Family run since 1976

Why Charles Day?

Experience

With 45+ years at the forefront of specialist cutting, we make procurement easy.

Service

We make procurement easy with simple and transparent custom service and years of industry expertise. Your parts are our priority.

Environmental Initiatives

Fully ISO 14001 accredited we are committed to making your power supply chain greener with solar laser power.

Capacity and Reliability

Operating the UK's largest capacity 24/7 across all services, we guarantee short lead times for projects of all sizes.

Quality

Operating to ISO 9001 and CE Marking BS/EN 1090-1 EXC4, we are proud to provide a second to none service.

Laser Cutting

Waterjet Cutting

HD Plasma Cutting

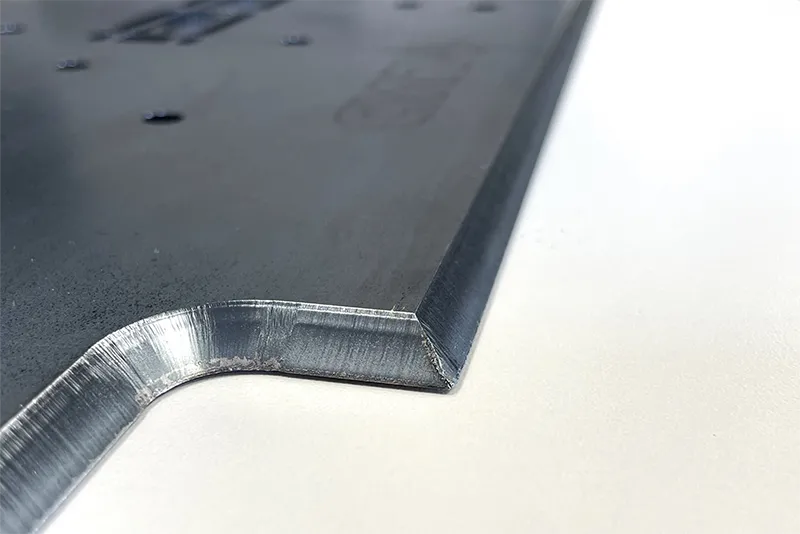

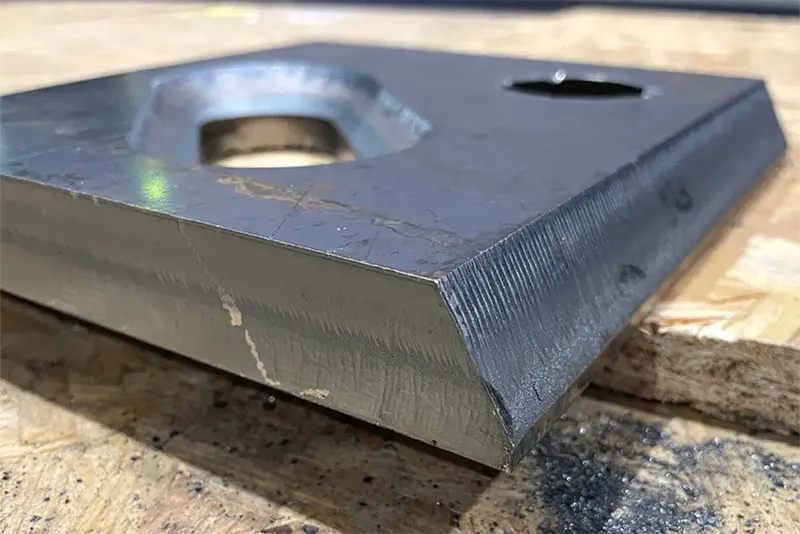

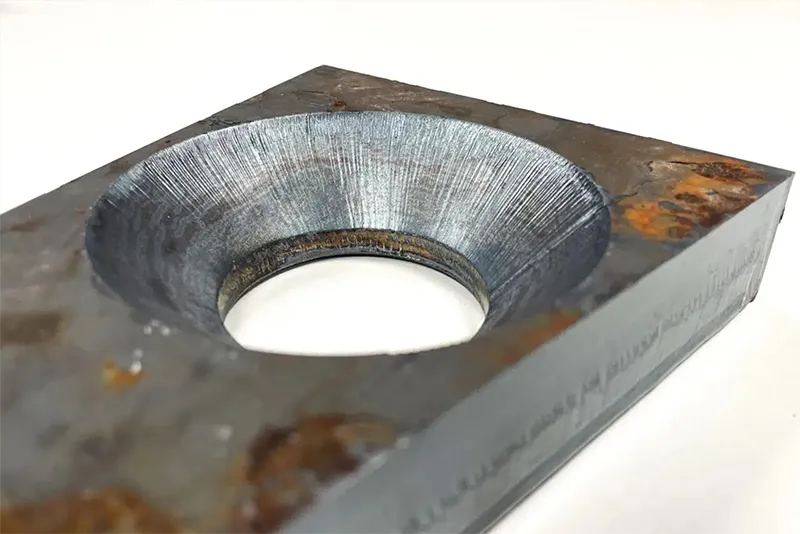

Chamfers & Bevels

Tube Laser Cutting

Flame Cutting

Profile Bending

Shot Blasting & Deburring

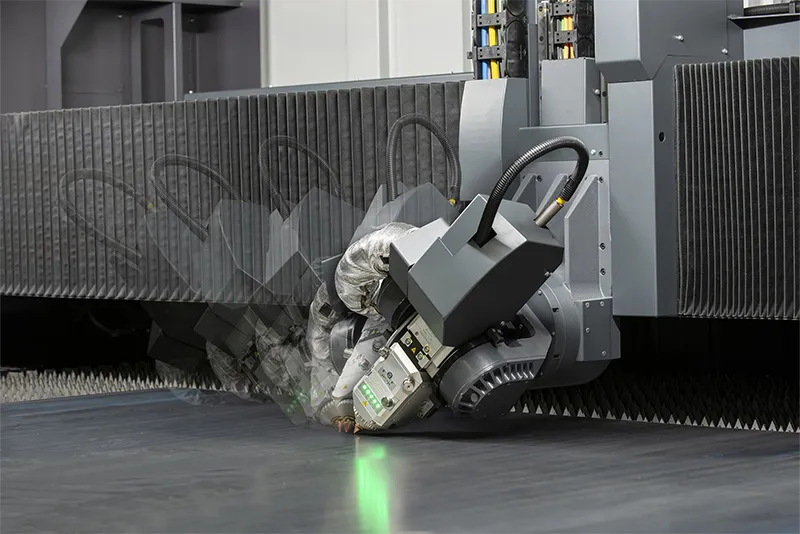

DYNAMIC Bevel, Countersink, and Weld Preparation Laser Cutting

- 50 degree bevel cutting on top and bottom edges

- 6510mm x 2600mm cutting bed

- Complex bevel geometries in up to 40mm thick material

Diverse Cutting

Flat and Tube Laser | Flame Cutting | Waterjet Cutting | Bevel Cutting

Quality and Expertise

BS EN 1090-1:2009 +A1 ISO 9001:2015 | ISO 14001:2015 | CE and UKCA Ready

Leading Capacity

24/7 Operation | High Volume and High Capacity | Innovative Technology

Value-Added Services

Design for Manufacture | Quality Materials and Finish Process | Exceptional Customer Service

Charles Day Steels

Diverse profile cutting services, combining state-of-the-art technology with industry leading capacity.

Established in 1976, Charles Day maintains a program of continuous investment, providing access to the latest technologies for companies choosing to outsource profile cutting. From drawing to delivery, Charles Day guarantees value through capability, speed, and accuracy.

Boasting the UK’s first 20kW laser cutting machine to the most powerful and largest waterjet cutting beds, Charles Day has become a true, one-stop profiling shop.

A range of finishing services removes the need for downstream weld preparation, delivering orders expertly finished and ready for assembly. Metal finishing services include the application of chamfers and bevels, deburring and shot blasting, and laser engraving.

Materials we cut

We can profile an extensive range of metal and non-metallic materials. With four different flatbed cutting methods under one roof, we can cut materials at depths between 0.1mm and 270mm. If a particular material is not in our exhaustive inventory, we can typically source it within 24-48 hours.

Plastics and Acrylics

8250mm x 4000mm

Thickness

Up to 230mm

Quality Assurance

Excellence. Accuracy. Compliance.

Got Questions? We have anwers

What types of metal profiling services does Charles Day Steels offer?

We provide a range of profiling services including laser cutting for flat and tube materials, waterjet cutting, plasma cutting, and flame cutting.

What materials can be profiled at Charles Day Steels?

Charles Day Steels is capable of profiling a wide range of materials such as steel, aluminium, stainless steel, copper, brass, bronze, titanium, and more.

What are the advantages of using waterjet cutting at Charles Day Steels?

Waterjet cutting at Charles Day Steels is ideal for materials that are sensitive to high temperatures. It leaves no heat-affected zone (HAZ), making it suitable for aerospace and nuclear applications.

How does Charles Day Steels ensure quality in our metal profiling services?

Charles Day Steels maintains certifications like BS EN 1090-1:2009 +A1, ISO 9001:2015 and ISO 14001:2015 to ensure adherence to high-quality standards and regulatory compliance. We also invest in the latest technologies for precise and efficient profiling.

Can Charles Day Steels handle complex and high-volume metal profiling projects?

Yes, we are equipped to handle both high complexity and high volume projects, with facilities like the UK’s first 20kW laser cutting machine and Waterjet Sweden BevelJet 60.

What finishing services are available after metal profiling?

Charles Day Steels offers a range of finishing services, including bevel cutting, deburring, shot blasting, laser engraving, and shot blasting.

What makes Charles Day Steels’ laser cutting services unique?

Our laser cutting service is known for rapid turnaround times and competitive costs with the latest technology, capable of handling large parts, high volume jobs, and complex projects without compromising on quality.

Does Charles Day Steels offer custom metal profiling solutions?

Yes, we provide customised solutions, working from drawings to delivery, and offering design for manufacture services to meet specific client requirements.

What is the lead time for metal profiling projects at Charles Day Steels?

We offer rapid turnaround times due to our 24-hour operation, although specific lead times may vary based on the project’s volume and complexity.

For more information, contact the team at Charles Day Steels today.