Profiling and cutting specialists Charles Day (Steels) Ltd have invested £1.5 million in three high powered machines from Bystronic UK.

The Sheffield based firm have added a Bycell Cross, 3kw BySprint Fiber 3015 and 6kw BySpeed Pro with full sheet and plate automation to their existing capacity of four flat bed laser machines, making Charles Day (Steels) Ltd one of the largest and diverse specialist profile cutting companies in the UK.

The motivation behind the ambitious investment is to establish the Charles Day (Steels) Ltd brand as the preferred destination for subcontract laser cutting of widgets, whilst also providing a platform for diversification into new industries. In addition to the firms traditional flame profile cutting service, the company now boasts a broad offering of flat bed, plasma cutting and waterjet cutting from a total of six laser cutting centres.

The increase in capacity is set to offer productivity across a full range of sheet thickness up to 25mm in carbon and stainless steel, in addition to the ability to process high volume cut components utilising the automation features of the 6kw BySpeed Pro. The result is a fully automated laser cutting cell incorporating sheet storage towers, eliminating downtime and reducing customer delivery lead times. The BySpeed Pro can optionally be equipped with either the ByLaser 4400 or with the ByLaser 6000, both of which guarantee a constantly high beam quality and impress through extremely low operating costs.

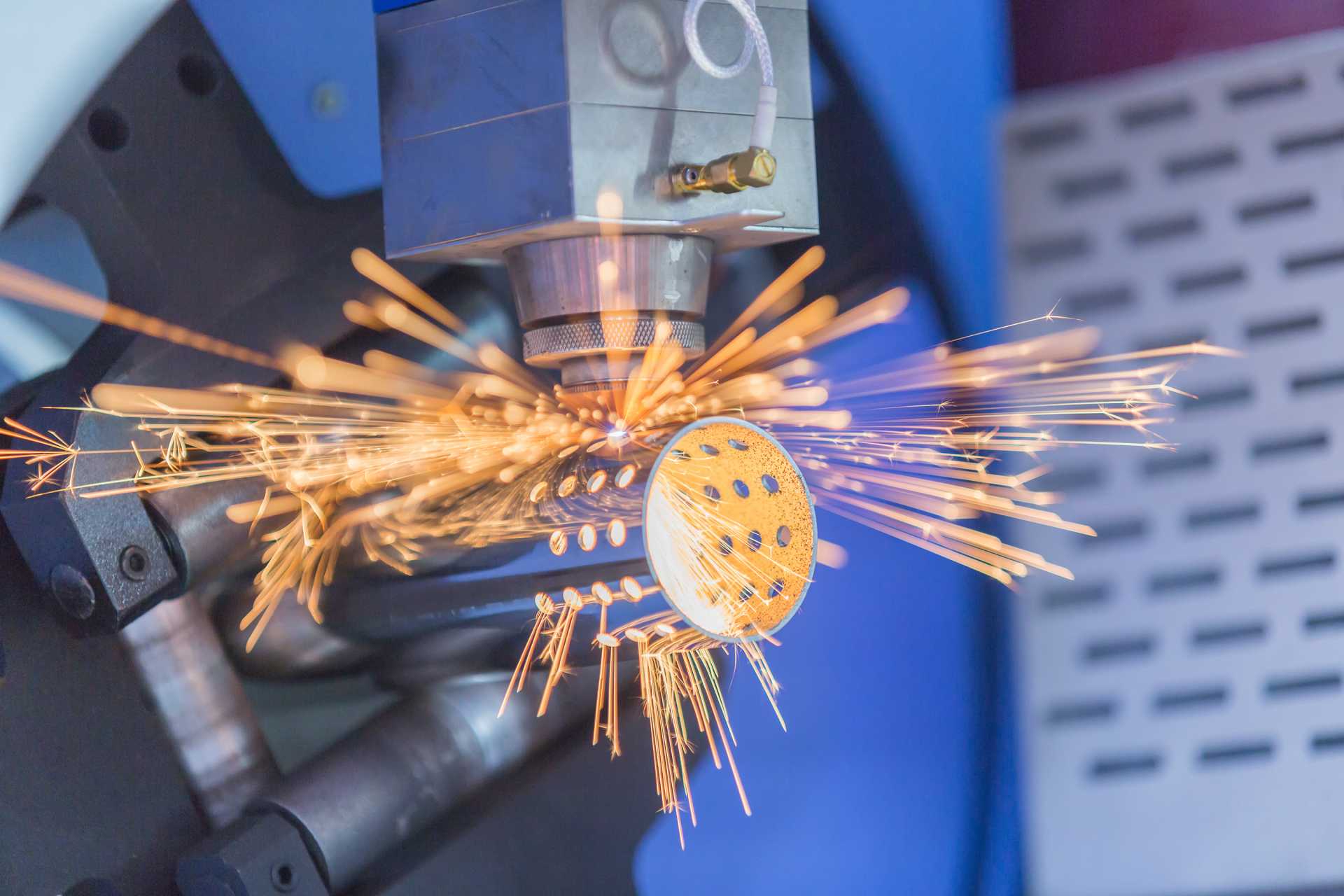

With the Bysprint Fiber 3015, Charles Day (Steels) Ltd have secured a machine based on the successful concept of the Bysprint Pro and one which is regarded as the swift sprinter in the Bystronic portfolio. Fiber laser cutting is an advanced alternative to conventional laser cutting processes, ideal when working with reflective materials or yellow metals such as brass and copper. In the thin sheet metal range up to four millimetres, the Bysprint Fiber 3015 ensures unprecedented parts output together with the highest precision of the parts.

The system’s drive and CNC concept guarantees high dynamics, so that the potential of the laser source can be converted into the fastest processing times whilst also having sufficient reserve so that sheets up to 12 millimetres thickness can be processed. The cutting head has been specially developed for fibre laser applications and the machine itself excels where traditional co2 lasers would struggle, something which Charles Day (Steels) Ltd believes will be complimented by their existing in house Waterjet cutting centre.

The company’s 8m x 4m cutting bed is the largest sub contract cutting bed in the UK, with multi head cutting is ideal for either short or continuous profiling. This allows for the cutting of thicker variations of brass, copper and bronze. The desired outcome is a move into new markets working with yellow metals, such as the medical or electronics sectors. Waterjet cutting is the fastest growing profiling method world-wide. Heat and gaseous materials free, the process brings accurate and cost effective cutting options to customers over a wide range of material, thickness and applications.

Charles Day Steels operate from a site which boasts hundreds of years of steel history and only minutes from the birthplace of stainless steel, which is celebrating 100 years in 2013 since its discovery by Harry Brearley.

In addition to the impressive portfolio of cutting and profiling services Charles Day have assembled, sister company, The Laser Cutting Co Ltd also boasts an offering of four dedicated tube, box, angle and channel laser cutting systems.

For more information on our laser cutting and prolfing service, please contact us and our Sales Team will be happy to help.