In the realm of manufacturing and fabrication, precision and efficiency are the cornerstones of success.

Here at Charles Day Steels, we understand more than most the importance of these factors during manufacturing processes, especially when efficiency and precision are of utmost significance. As industries become increasingly competitive and technology-driven, businesses are continuously seeking cutting-edge solutions to optimise their processes and deliver high-quality products.

Benefits of Laser Cutting

Offering industry-leading laser cutting solutions using our extensive suite of state-of-the-art laser cutting machines, our laser cutting services offer a host of benefits that not only elevate the quality of end products but also streamline operations and supply chains for enhanced efficiency.

Some of the many benefits of laser cutting include:

Unparalleled Precision

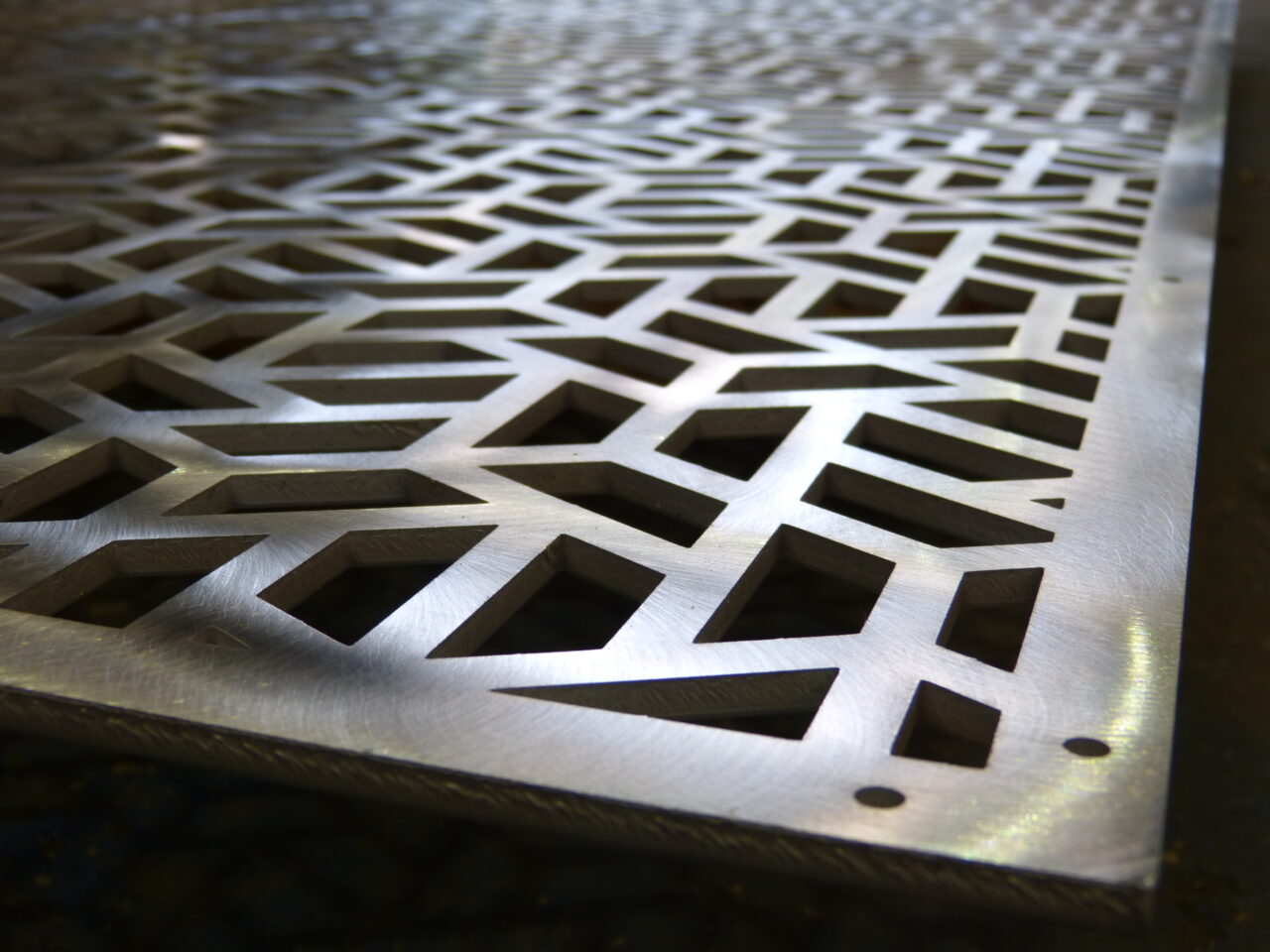

Laser cutting is renowned for its unparalleled precision. Unlike traditional cutting methods, which can result in jagged edges and material distortion, laser cutting employs a focused and concentrated beam of light to slice through materials with unparalleled accuracy. Our Fibre Laser cutting machines can achieve intricate patterns and delicate designs which can be reproduced flawlessly, enabling us to create products that align precisely with our client’s specifications.

Material Versatility

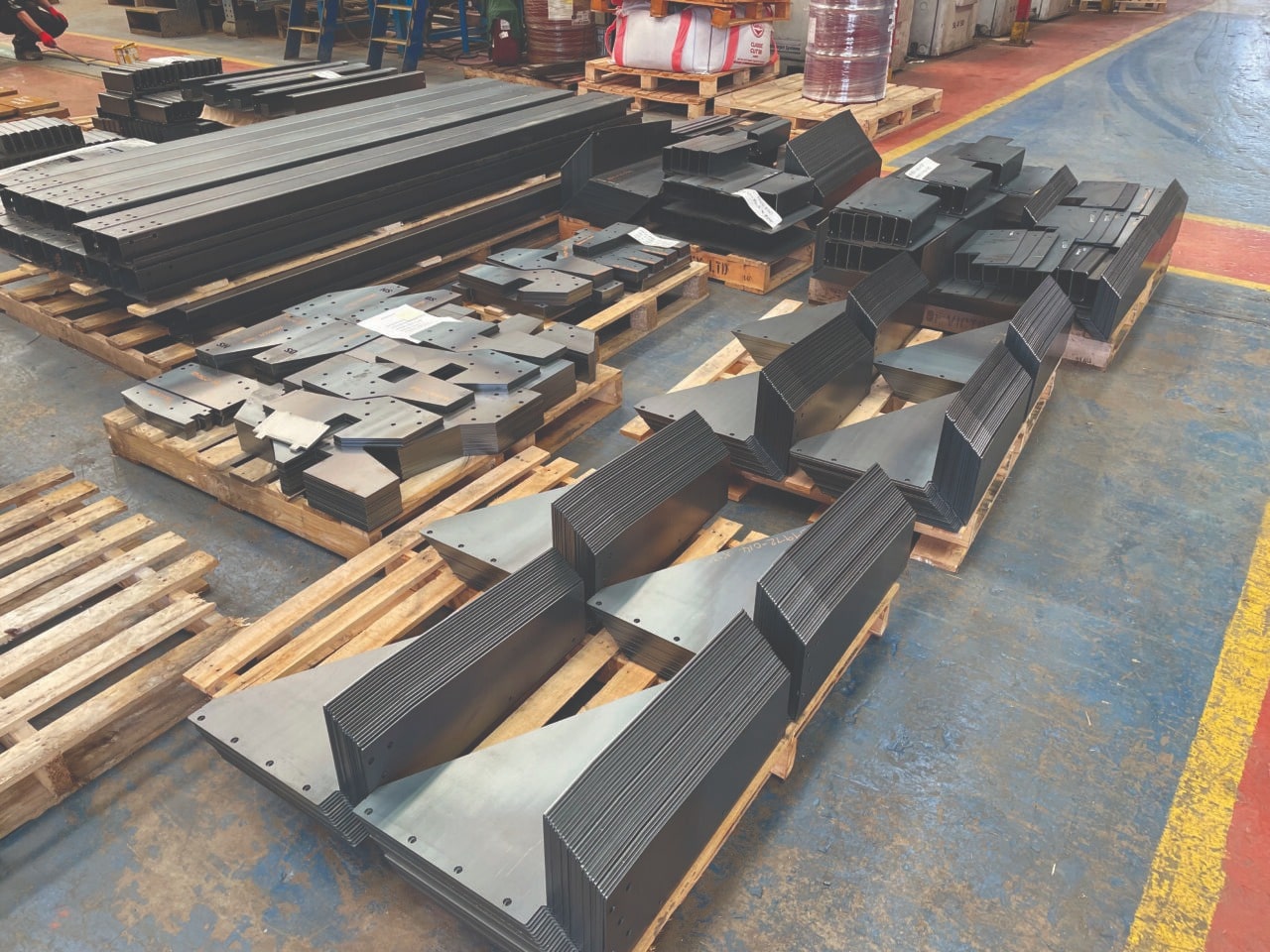

One of the standout advantages of laser cutting is its ability to tackle a diverse range of materials. Perfect for thin sheet metal and reflective materials like stainless steel, carbon and mild steels, titanium, copper, brass and bronze, aluminium and alloys, laser cutting offers remarkable versatility. This eliminates the need for multiple cutting tools or processes, streamlining production and reducing setup times. Manufacturers can seamlessly transition between materials, allowing for greater flexibility in design and quicker response to market demands.

Minimised Waste

Traditional cutting techniques often result in substantial material wastage due to wider kerfs and inefficient cutting paths. Laser cutting’s narrow and focused beam significantly reduces wastage by ensuring precise cuts that maximise material utilisation. This not only conserves resources but also contributes to cost savings €”a crucial consideration for any manufacturing operation.

Intricate Designs Made Effortless

Our laser cutting services enable the creation of intricate and complex designs that were once deemed unattainable or highly labour-intensive. The precision of laser cutting technology means that even the most intricate of patterns can be accurately reproduced, unleashing a realm of creative possibilities such as laser etching and engraving, which can be taken advantage of by architects, artists, and manufacturers alike.

Swift and Efficient Processing

At Charles Day Steels, we recognise that efficiency is a hallmark of laser cutting. The speed at which the laser beam traverses the material, combined with the ability to pre-program cutting paths, results in rapid and consistent processing. This translates into shorter production cycles, reduced lead times, and a higher output capacity €”a definite advantage in today’s fast-paced business environment.

Minimal Finishing Work

Laser cutting’s clean and precise cuts often translate to finished pieces that require minimal, if any, post-processing. The absence of burrs, sharp edges, and heat-affected zones reduces the need for time-consuming and costly finishing work. This means that we can allocate our resources more efficiently and deliver end products to our customers without delay, by taking advantage of our Deburring and Vibro-deburring service.

Environmental Friendliness

As the world increasingly gravitates towards sustainable practices, laser cutting emerges as an eco-friendly option. Compared to traditional cutting methods that generate more waste and emissions, laser cutting is a cleaner alternative. Its energy efficiency and reduced material wastage align seamlessly with our environmentally conscious manufacturing practices.

Trust Charles Day For Laser Cutting Precision

In the realm of modern manufacturing, laser cutting stands out as a masterpiece of precision and efficiency. The benefits of laser cutting speak for themselves, and its ability to carve intricate designs, navigate various materials, and expedite production processes makes it a vital asset for industries seeking to excel in a competitive market.

Key features of Charles Day’s fibre laser cutting services include:

- Handle sheet sizes up to 6m x 2.5m

- Metal cutting up to 50mm thick

- Faster than CO2 with exceptional precision and output

- Minimal distortion due to low heat generation

- 7 fibre lasers cutting 24 hours a day, 7 days a week

- Competitive price per part.