With over 4 decades of experience in the industry, we recognise that metal finishing is an essential process in the manufacturing and crafting of metal products. It not only enhances the appearance of the metal but also improves its durability, resistance to corrosion, and surface friction.

Here at Charles Day Steels, we not only provide a host of metal profiling services trusted across the UK and beyond, but we also offer exclusive metal surface finishing services such as Deburring and Vibro Deburring and Shot Blasting; enhancing your profiled parts for an array of industries and applications.

Understanding Metal Finishing

Metal finishing is a broad term that refers to the process of altering a metal’s surface to achieve specific properties. It can involve cleaning, polishing, and coating the surface of the metal. The primary goals of metal finishing are:

Enhancing Appearance:

Polishing and plating can provide a shiny, smooth, or even textured surface.

Increasing Durability:

Certain finishes protect the metal from wear and tear, corrosion, and environmental factors.

Improving Electrical Conductivity:

Some finishes are used to increase the conductivity of the metal.

Reducing Surface Friction:

Finishes like electroplating can reduce friction, making the metal more suitable for moving parts.

Types of Metal Finishing Processes

Electroplating

Electroplating uses electrical current to coat metals with a layer of another metal, like nickel or chromium, enhancing corrosion resistance and aesthetics.

Powder Coating

A dry finishing process where powder material is sprayed and cured on the metal, resulting in a thick, durable coating.

Anodizing

Used mainly for aluminium, it forms a corrosion-resistant oxide layer and allows dyeing in various colours.

Sandblasting

This involves propelling abrasive material against the metal to clean and prepare its surface.

Buffing and Polishing

These are used to smooth the metal’s surface for a mirror-like finish, often for decorative purposes.

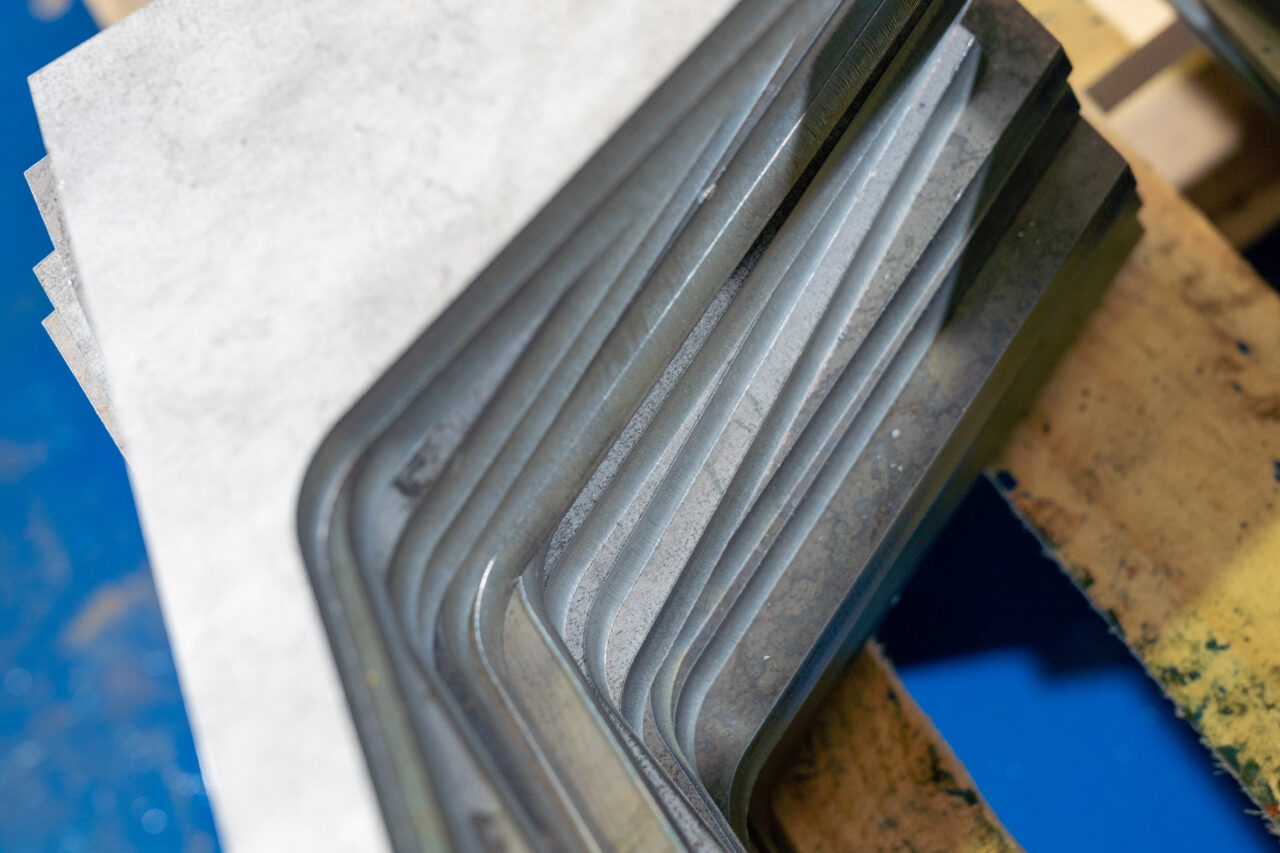

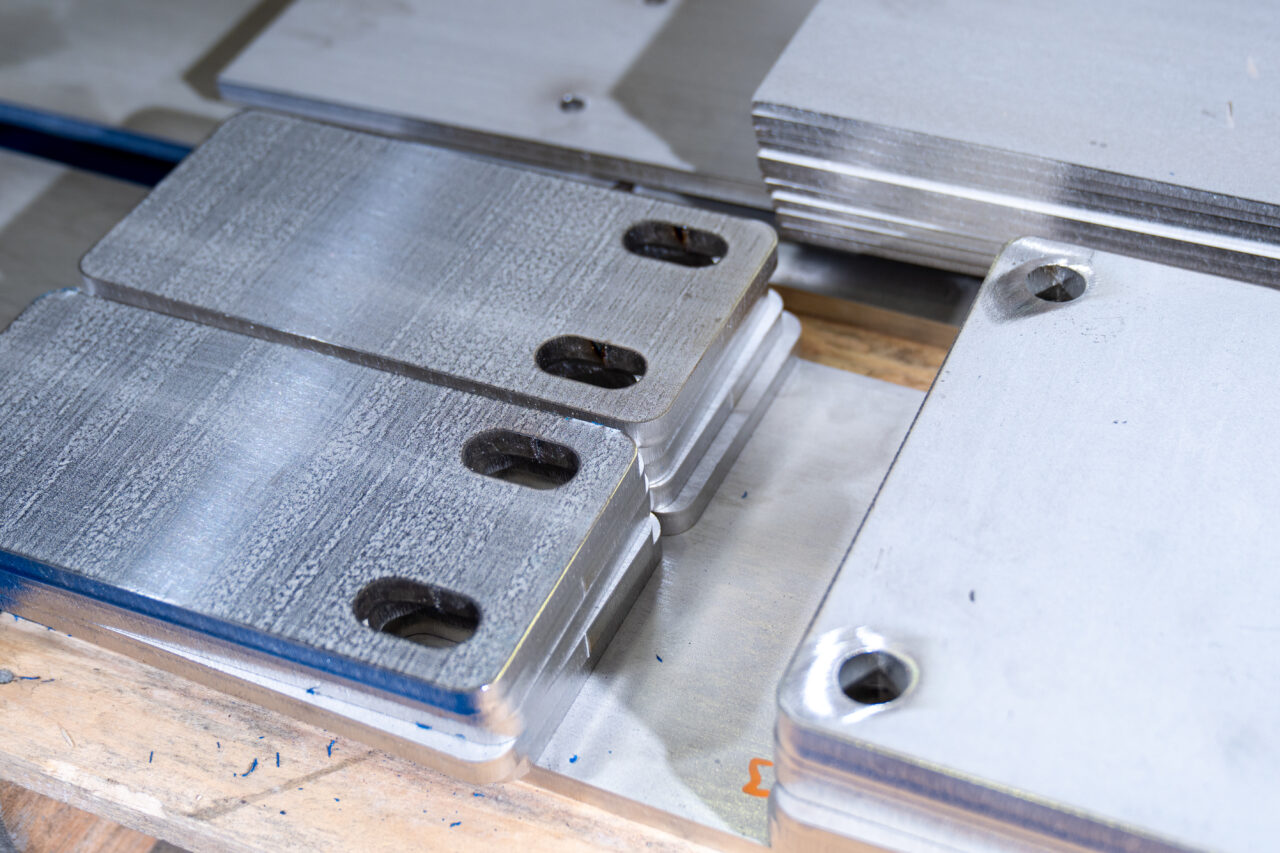

Deburring & Vibro Deburring

Deburring and Vibro-Deburring is crucial for removing rough edges or protrusions on metal. It’s essential for safety, functionality, and aesthetics. Techniques include manual deburring with tools, vibratory finishing, and thermal deburring.

Shot Blasting

Shot Blasting cleans, strengthens, or polishes metal. It involves propelling small steel or mineral particles against the metal surface at high speed. This process is excellent for preparing metal for further finishing, removing surface contaminants, and inducing surface compressive stress for increased strength.

Choosing the Right Metal Finishing Process

Factors to consider:

Material Type:

Different metals have different finishing needs.

Desired Outcome:

Prioritise durability, aesthetics, or corrosion resistance.

Environmental Conditions:

Consider the exposure of the metal.

Cost and Time Efficiency:

Balance the budget and timeline with the process choice.

Applications of Metal Finishing

Automotive Industry:

Parts need durability and aesthetics.

Aerospace Industry:

Precision and corrosion resistance are key.

Consumer Electronics:

For durable, attractive finishes.

Construction:

Architectural elements require both functionality and aesthetics.

Metal Finishing Services at Charles Day Steels

Metal finishing, including Deburring and Vibro-Deburring and Shot Blasting, is vital for modern manufacturing, significantly enhancing the performance, durability, and appearance of metal products. With advancing technology, the field is rapidly evolving, offering new possibilities for innovation.

For professional metal profiling and metal finishing services, contact the team at Charles Day Steels today. We are always happy to lend our expertise and services wherever possible.