Here at Charles Day Steels, we’ve mastered the art of custom fabrication through cutting-edge technology and over 4 decades of expertise.

Metal forming plays a pivotal role in custom fabrication by enabling tailored solutions, fostering design freedom, ensuring seamless integration, enhancing strength, promoting efficiency and cost-effectiveness, accommodating diverse materials, and facilitating rapid prototyping and iteration. As a foundational process in the custom fabrication toolkit, metal forming empowers manufacturers to meet the unique challenges of custom projects with precision, efficiency, and innovation.

What is Metal Forming?

Metal forming is a manufacturing process that involves shaping metal into desired shapes and dimensions through mechanical deformation. It’s a broad category encompassing various techniques, each suited for different applications and producing different outcomes. The primary aim of metal forming is to alter the metal’s shape, thickness, or properties without removing material.

Why Metal Forming is Crucial in Custom Fabrication

When it comes to custom fabrication, each project presents unique challenges and requirements. Metal forming is essential for custom fabrication for a number of reasons, some of which include:

Tailored Solutions

Custom fabrication demands solutions that are precisely tailored to meet the specific needs of each project. Metal forming techniques offer the flexibility to shape raw materials into custom profiles, geometries, and sizes, ensuring that every component fits seamlessly into the larger assembly.

Design Freedom

Unlike off-the-shelf components, custom fabrications often require complex shapes and intricate designs. Metal forming empowers greater creativity, enabling the realisation of innovative concepts and unconventional geometries that would be impractical or impossible to achieve with standard parts.

Seamless Integration

In custom fabrication, every piece must fit together flawlessly to create a cohesive whole. Metal forming facilitates the creation of components with precise dimensions and tolerances, ensuring seamless integration into the overall assembly. Whether it’s bending, shaping, or extruding, metal forming techniques enable the production of parts that meet exact specifications with minimal variation.

Strength and Durability

Custom fabrications often serve critical functions in demanding environments, requiring components with exceptional strength and durability. Metal forming processes such as forging and extrusion impart superior mechanical properties to the finished parts, enhancing their resilience and longevity in service.

Efficiency and Cost-Effectiveness

While custom fabrication may entail higher upfront costs than off-the-shelf solutions, metal forming offers long-term benefits in terms of efficiency and cost-effectiveness. By optimising material usage, minimising waste, and streamlining production processes, metal forming helps to reduce overall project costs while maximising value and performance.

Adaptability to Diverse Materials

Custom fabrication projects often involve a wide range of materials, from steel and aluminium to exotic alloys and composites. Metal forming techniques are inherently versatile, capable of accommodating diverse materials and adapting to their unique properties, ensuring consistency and quality across different substrates.

Rapid Prototyping and Iteration

Metal forming enables rapid prototyping and iteration, allowing designers and fabricators to quickly refine designs, test concepts, and make adjustments. Whether it’s experimenting with different shapes or fine-tuning dimensions, metal forming facilitates agility and responsiveness throughout the fabrication process.

Types of Metal Forming Techniques

Metal forming techniques encompass a wide range of processes used to shape metal into desired forms. Some common metal forming techniques include:

Casting

Molten metal is poured into a mold where it solidifies into the desired shape. This can be done using various methods such as sand casting, investment casting, die casting, etc.

Forging

Metal is shaped by applying compressive force either manually or with the help of machinery. Forging can be done using different methods like hammer forging, press forging, drop forging, etc.

Rolling

Metal is passed through a pair of rotating rolls to reduce its thickness or change its shape. Rolling can be used for flat products like sheets and plates or long products like bars and rods.

Drawing

Metal is pulled through a die to reduce its cross-section and increase its length. Drawing is commonly used to produce wires, tubes, and other elongated shapes.

Extrusion

Metal is forced through a die to produce long, continuous shapes with a constant cross-section. Extrusion is widely used for producing profiles, tubes, and rods.

Stamping

Metal sheets are pressed between dies to cut or form them into desired shapes. Stamping is commonly used in mass production for producing components with high precision.

Spinning

A rotating blank is shaped over a mandrel using pressure applied by tools. Spinning is often used to produce cylindrical or conical shapes such as pots, pans, and decorative items.

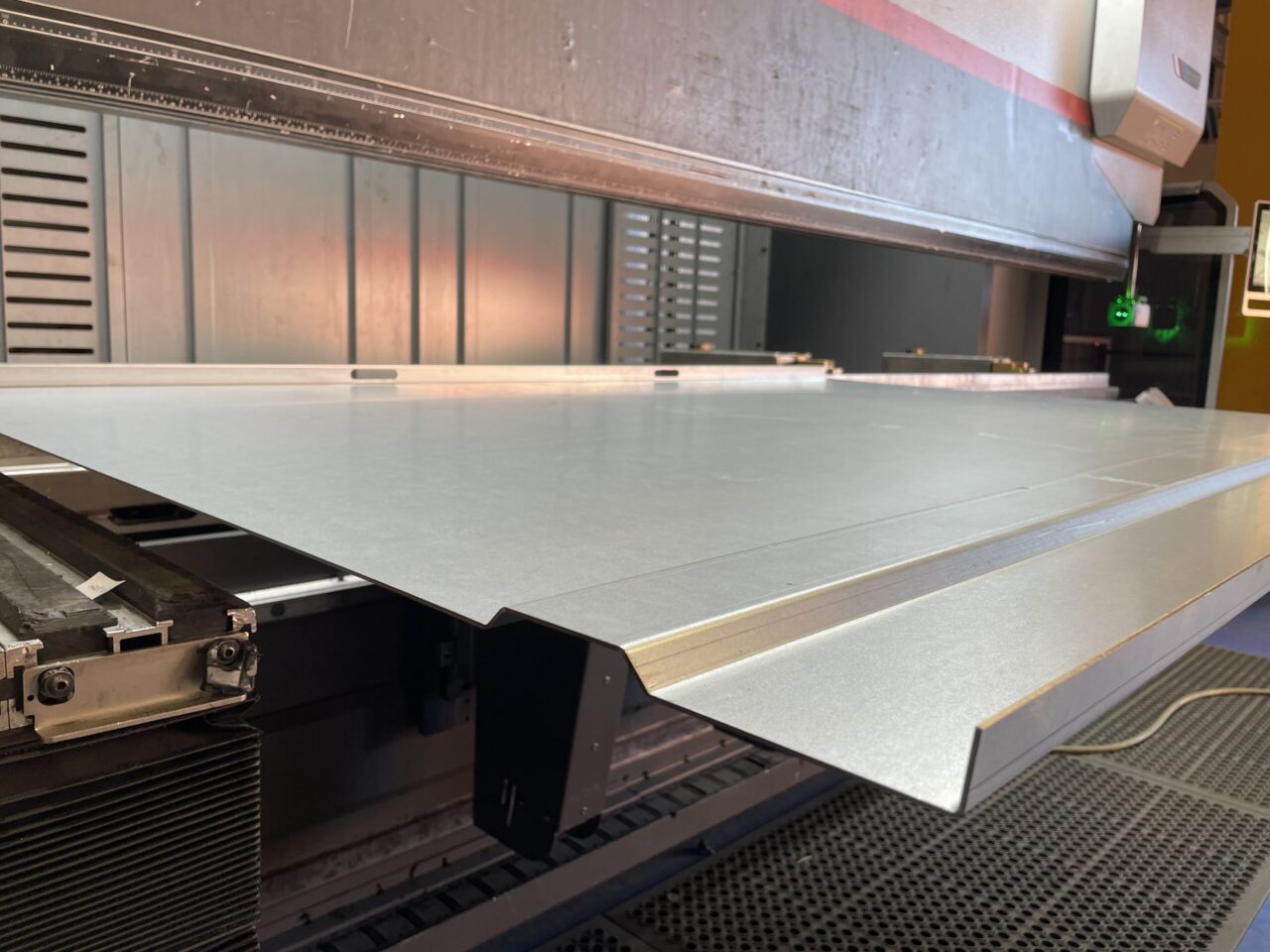

Bending & Pressing

Metal is bent to achieve desired angles or shapes using tools such as press brakes, rollers, or specialised bending machines.

Hydroforming

Fluid pressure is used to shape metal sheets or tubes into complex forms using a die. Hydroforming allows for the production of lightweight and structurally efficient components.

Powder Metallurgy

Metal powders are compacted into desired shapes and then sintered to bond the particles together. Powder metallurgy is used for producing parts with complex shapes or materials that are difficult to process by conventional methods.

These techniques can be combined or modified to suit specific manufacturing requirements, and advancements in technology continue to expand the possibilities within the field of metal forming.

Beyond Cutting: The Power of Metal Forming

At Charles Day Steels, our arsenal of cutting technologies includes tube laser cutting, waterjet cutting, flame cutting and plasma cutting. Each method offers unique advantages, from the unrivalled accuracy of laser cutting to the efficiency of flame cutting for high-volume production runs. With cutting tolerances ranging from +/- 0.25mm to +/- 6.0mm and the ability to handle materials up to 270mm thick, we ensure that every piece meets the highest standards of quality and craftsmanship.

But metal fabrication is more than just cutting, and that’s where our metal forming capabilities come into play. Our profile bending services allow us to mould metal with precision, handling even the most challenging geometries and heavy-duty materials with ease. Whether it’s creating structural components or intricate architectural features, our suite of brake press machines and extensive tooling library ensures that every bend is executed flawlessly.

Adding the Finishing Touches

No project is complete without the finishing touches, and at Charles Day Steels, we offer a range of value-added services to elevate your fabrication experience. From applying chamfers and bevels to shot blasting and deburring, we ensure that every piece is expertly finished and ready for assembly. By reducing downstream manufacturing processes and improving part longevity, our finishing services streamline production and enhance overall efficiency.

The Charles Day Steels Advantage

What sets Charles Day Steels apart is not just our cutting-edge technology or industry-leading capacity—it’s our commitment to quality and expertise. With certifications including BS EN 1090-1:2009 +A1 and ISO 9001:2015, we adhere to the highest standards of excellence in everything we do. From rapid turnaround times to personalised design for manufacturing services, we strive to exceed our customers’ expectations at every turn.

Whether you’re shaping steel, aluminium, stainless steel, or exotic alloys, trust Charles Day Steels to deliver unparalleled quality and craftsmanship every step of the way. Get in touch with us today and discover the difference that metal forming can make in your custom fabrication projects.