A pioneer in metal profiling, Charles Day Steels, proudly announces the launch of their progressive 50-degree Laser Bevel Cutting machine.

This innovative addition to their extensive suite of laser cutting and profiling services promises to redefine efficiency and precision in metal fabrication.

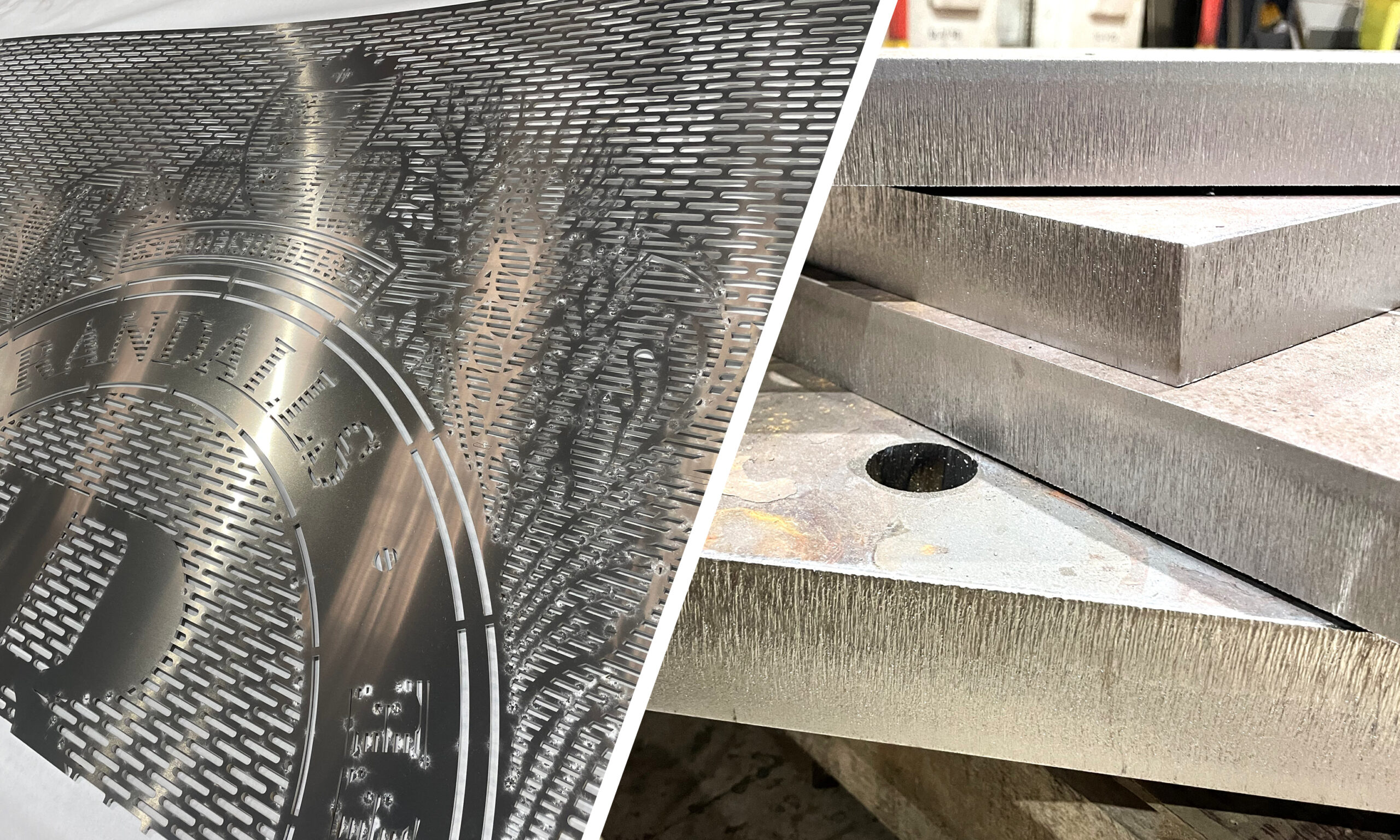

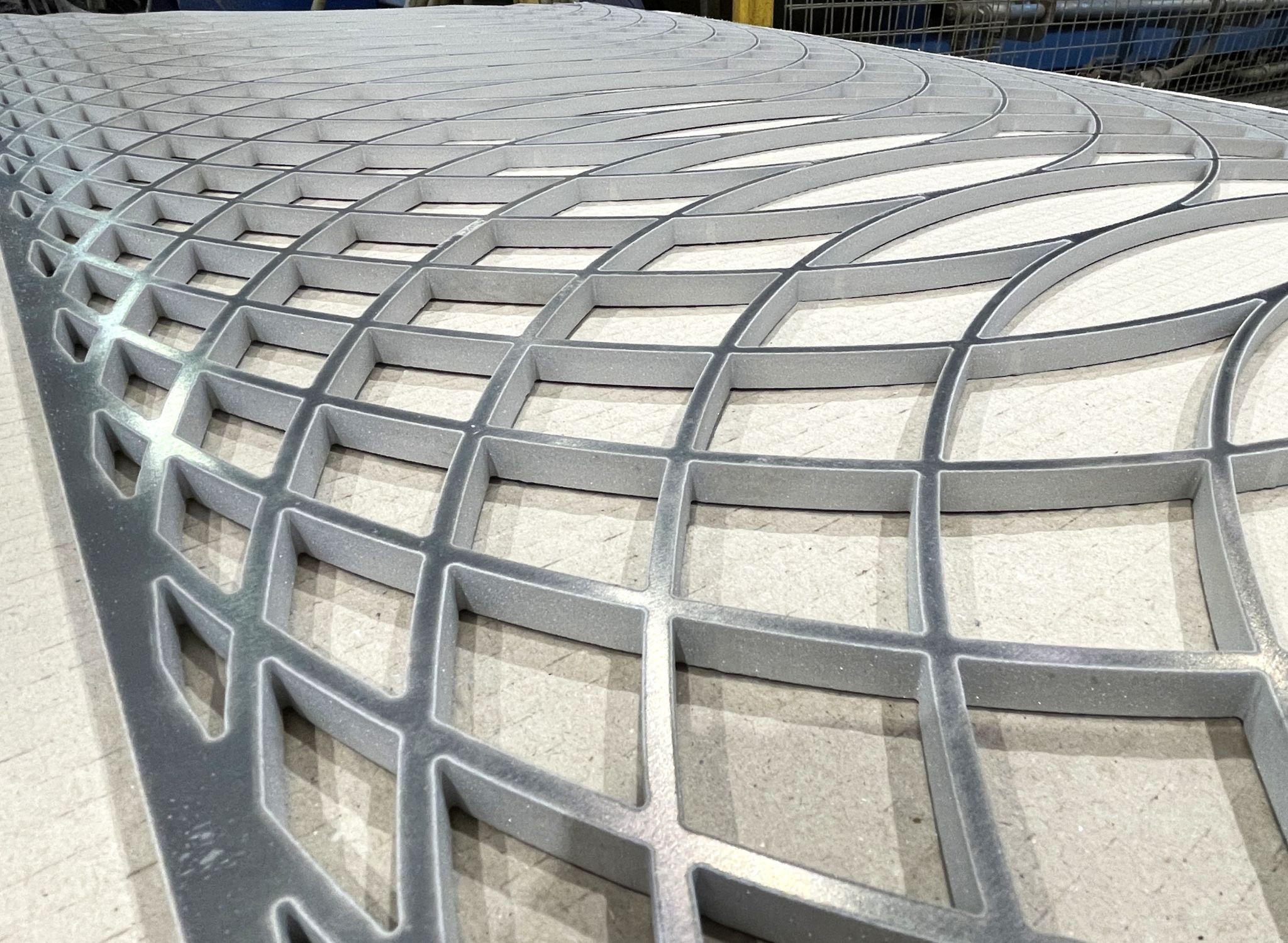

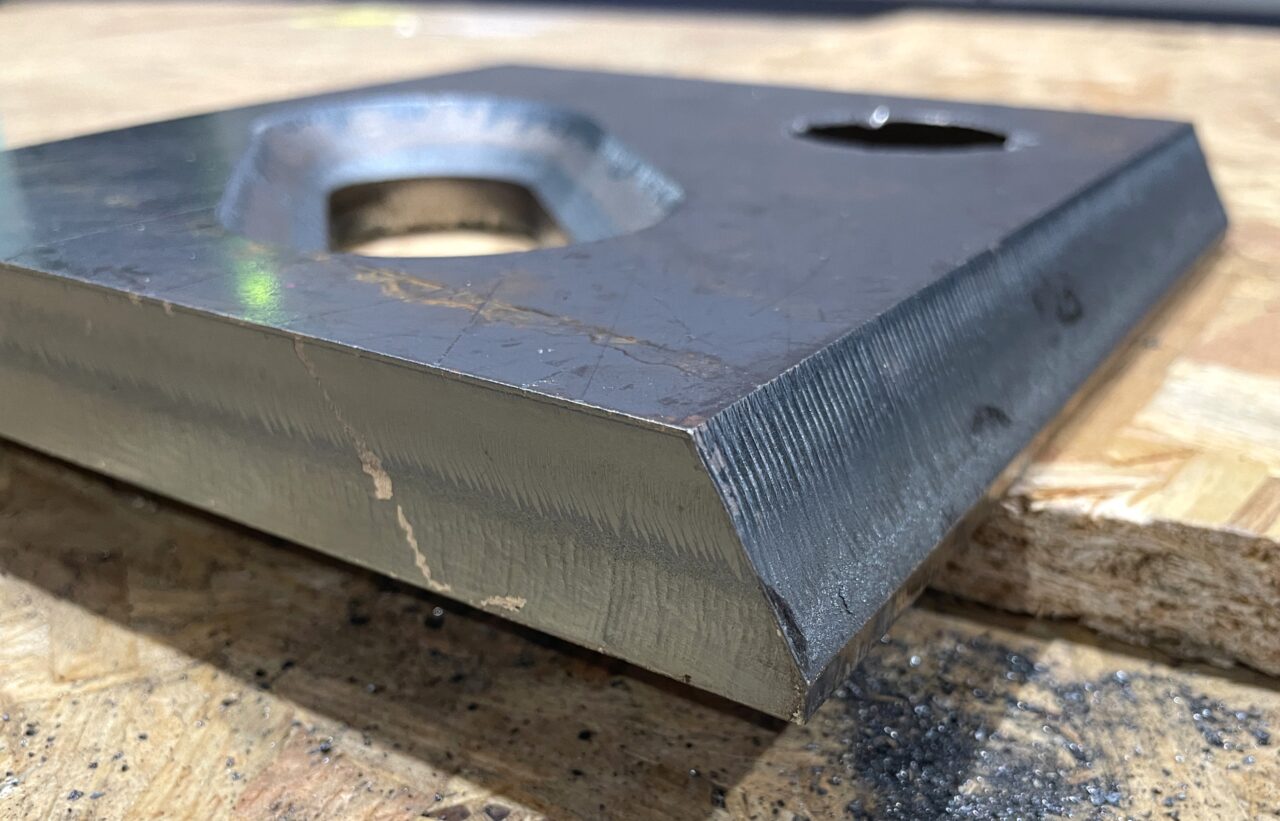

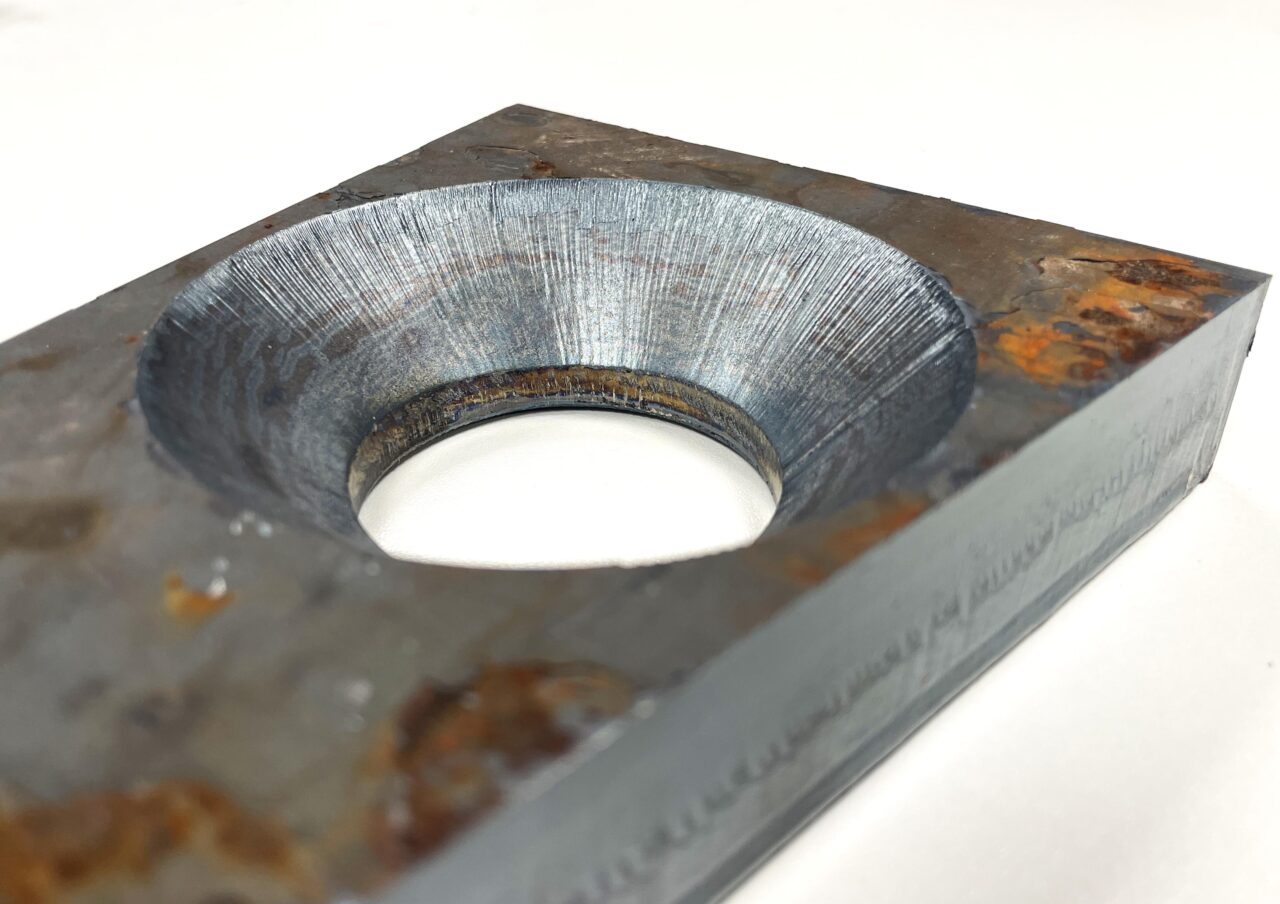

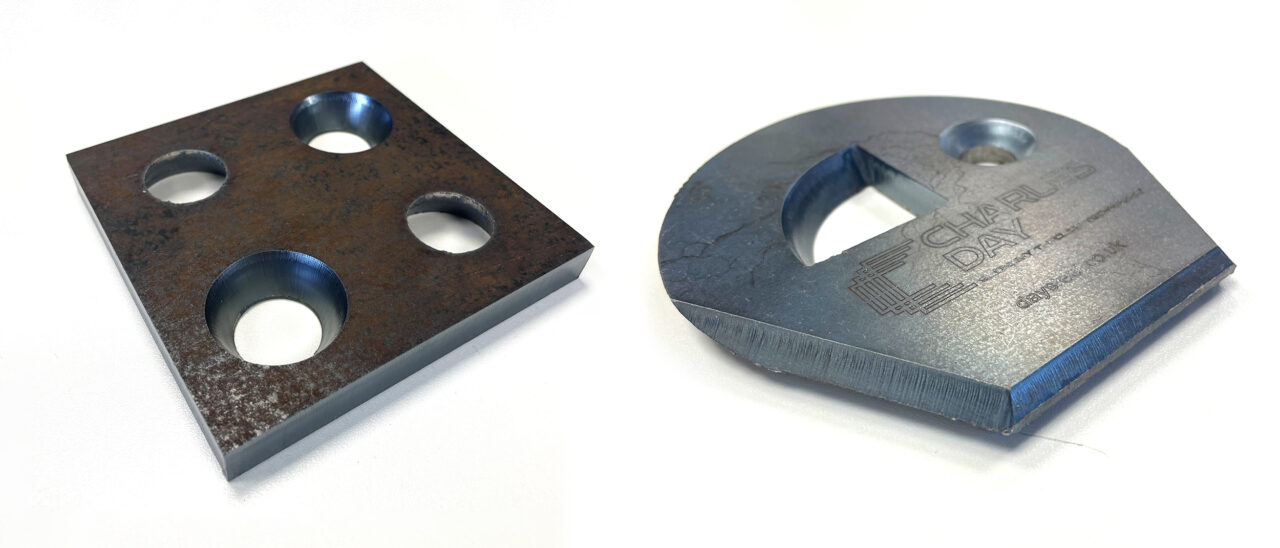

One of the stand-out features of the new laser is its unparalleled versatility, enabling cuts at any angle up to 50 degrees from a 12kw laser power source. Set to revolutionise the industry with its ability to eliminate the need for manual grinding and weld preparation, this investment serves as a powerful complement to their existing Waterjet Bevel capabilities.

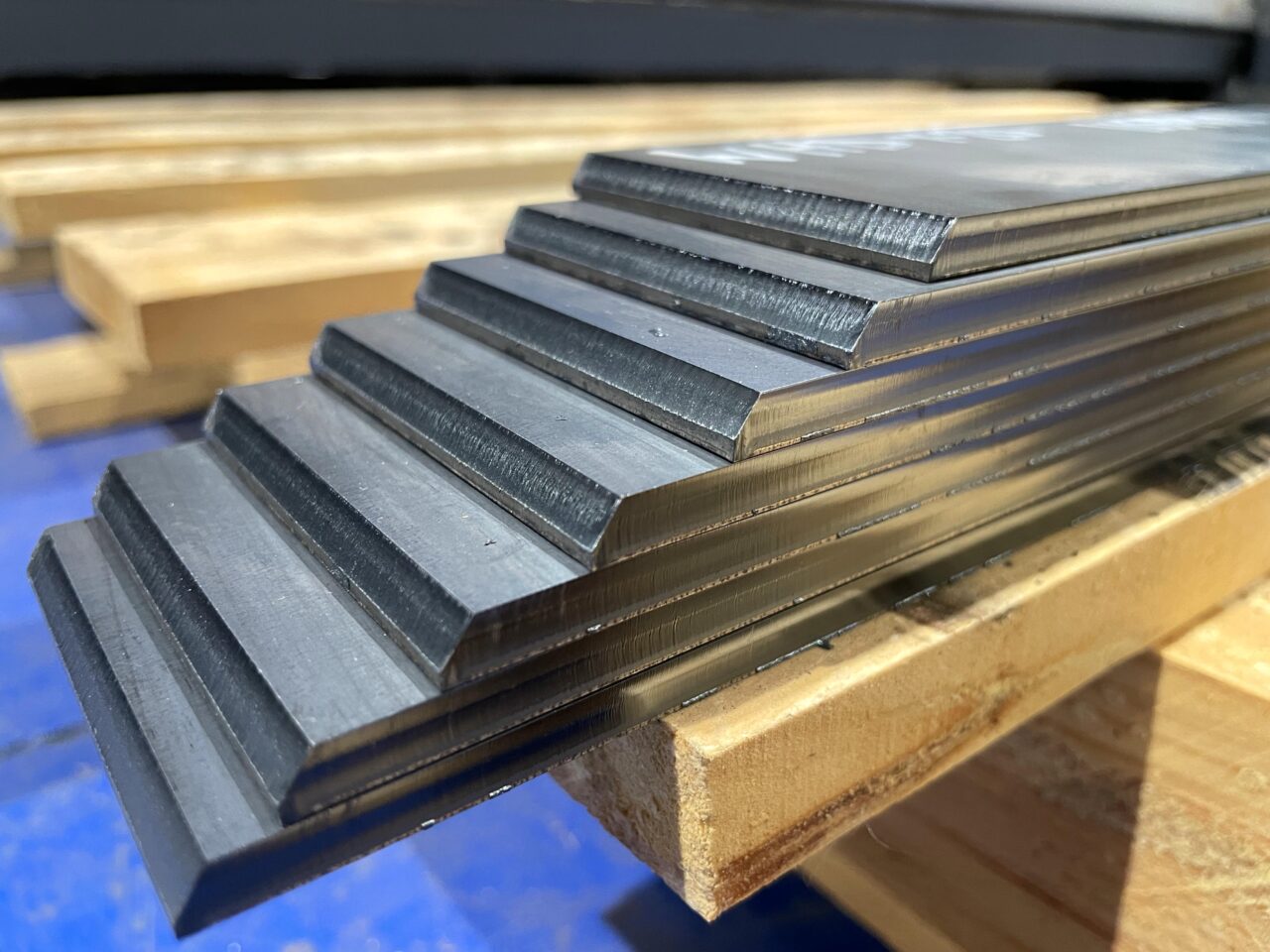

The new machine boasts a large 6510mm x 2600mm bed, allowing for the rapid processing of substantial bevel parts up to 40mm thick. This advancement ensures a seamless transition from cutting to assembly, offering drastically reduced post-processing time and labour costs.

The ability to laser bevel cut offers two key benefits. First, it significantly cuts costs for downstream fabrication by providing parts that are already prepped for fabrication with weld preps. This eliminates the need for additional preparation, saving both time and money.

Second, it efficiently handles parts that would otherwise require bevelling or countersinking through traditional machining methods, which are both expensive and time-consuming. By incorporating laser bevel cutting, the process becomes more streamlined and cost-effective. This is particularly effective when dealing with harder material such as wear and amour plate which carry with them the challenges of machining harder materials.

Charlie Day, grandson of the Founder and Sales and Business Development Director at Charles Days, spoke about their latest investment:

“With the launch of our new Laser Bevel Cutting technology, we are taking a significant step forward in our service capabilities by providing fabrication-ready parts in a single process. This addition means we can offer clients the very best value not just in our cutting service, but also through reducing their downstream production costs.”

Established in Sheffield, the city of steel, Charles Day continues to lead the way in profile-cutting innovation, leveraging over four decades of expertise and cutting-edge technology to serve their customers across various sectors, including construction, automotive, and aerospace, all with industry leading capacity and reliability.