60 Degree

Bevel cutting

9000mm x 4000mm

Cutting bed

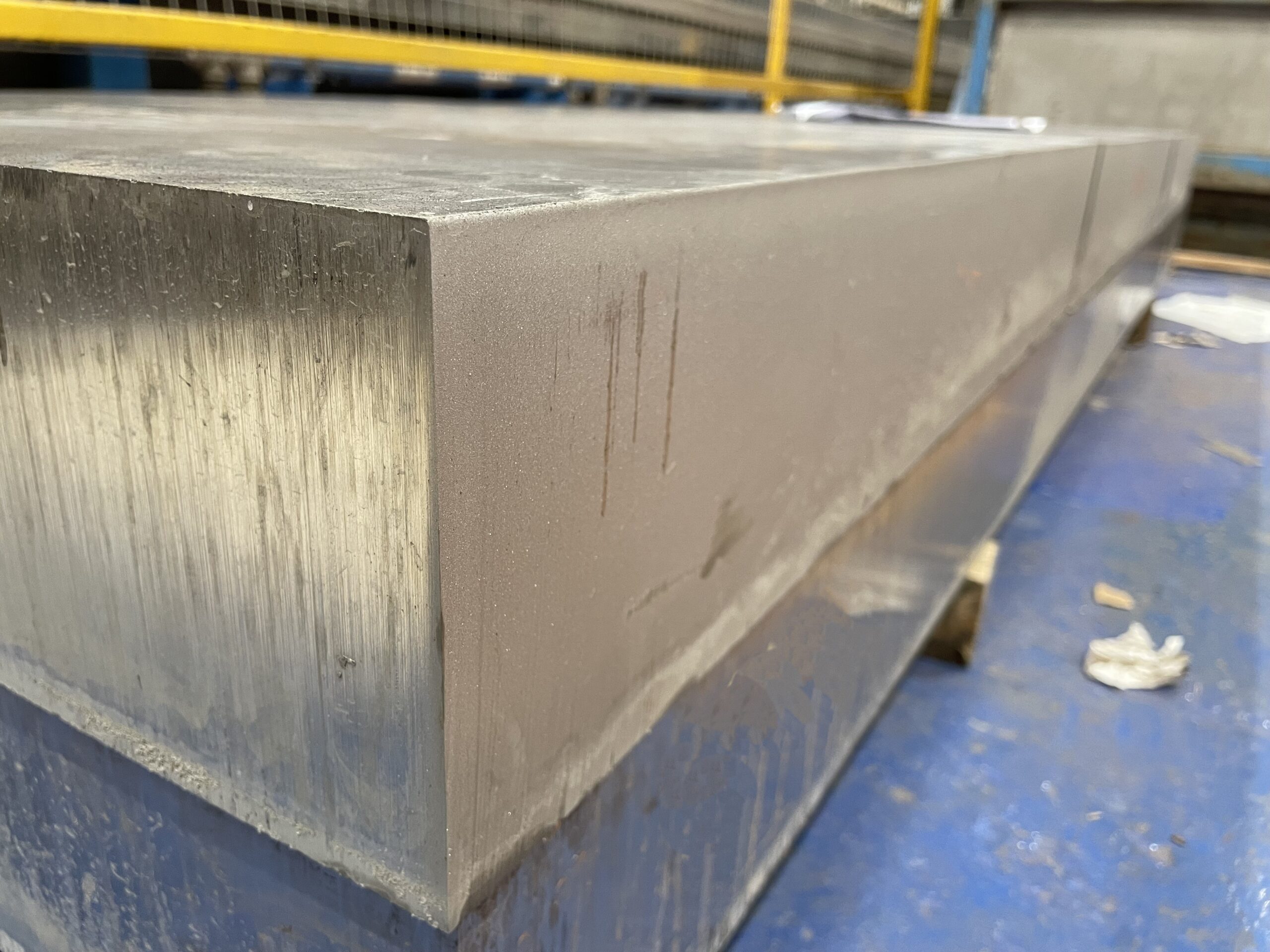

Up to 300mm

Cutting thickness

Efficient & Cost Effective

Machining alternative

Cold Cutting

Process

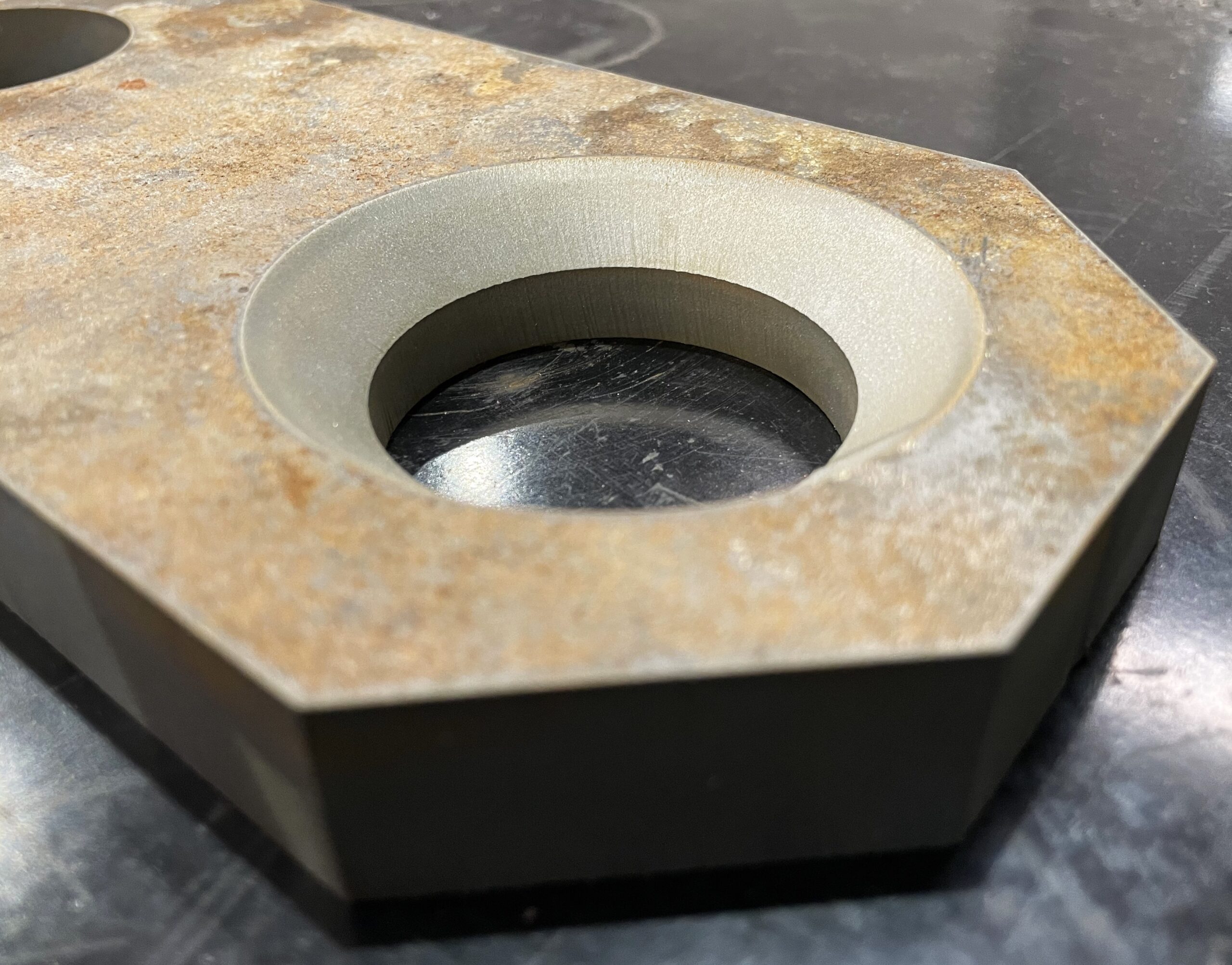

Discover Superior Precision and Versatility with Our Water Bevel Cutting Services

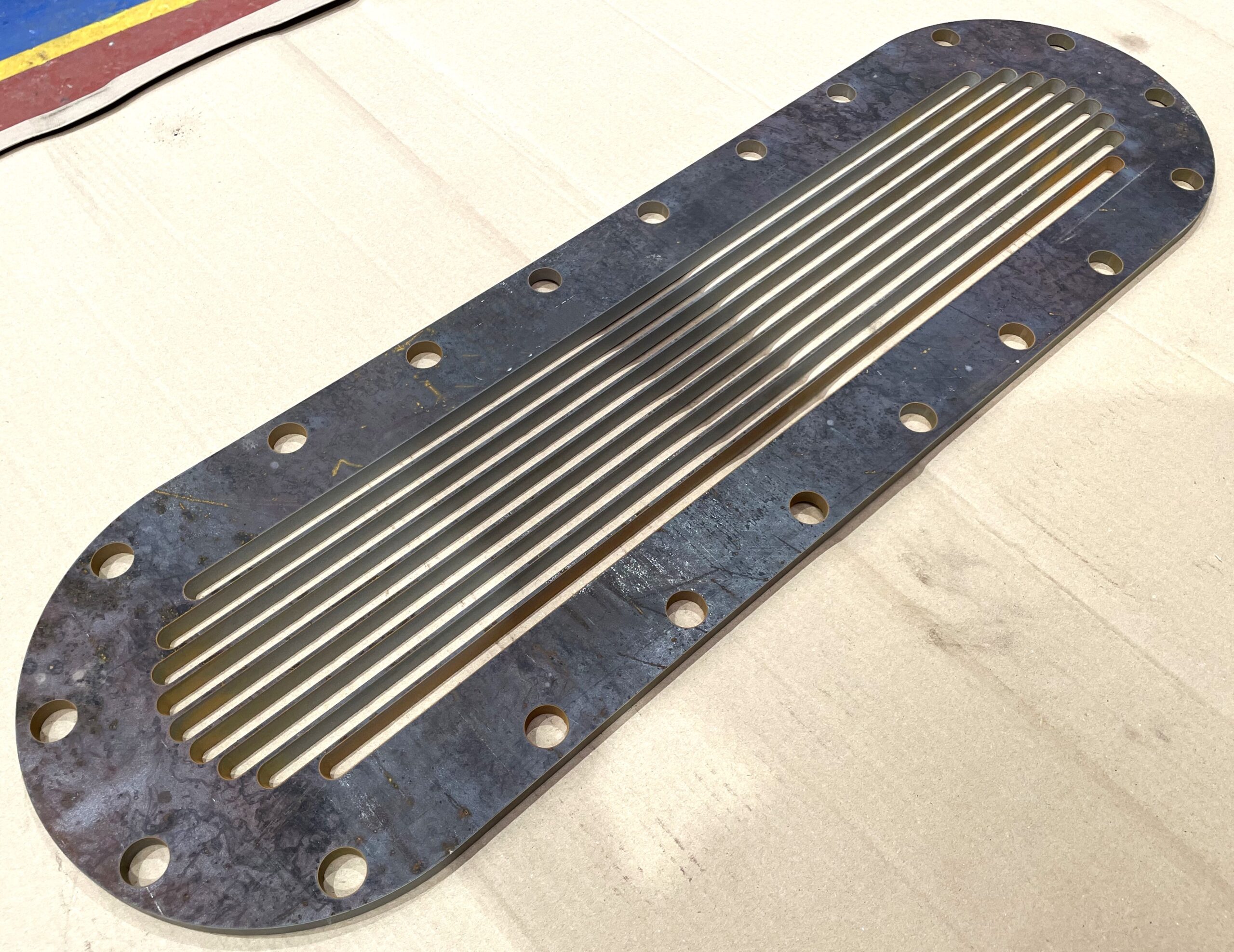

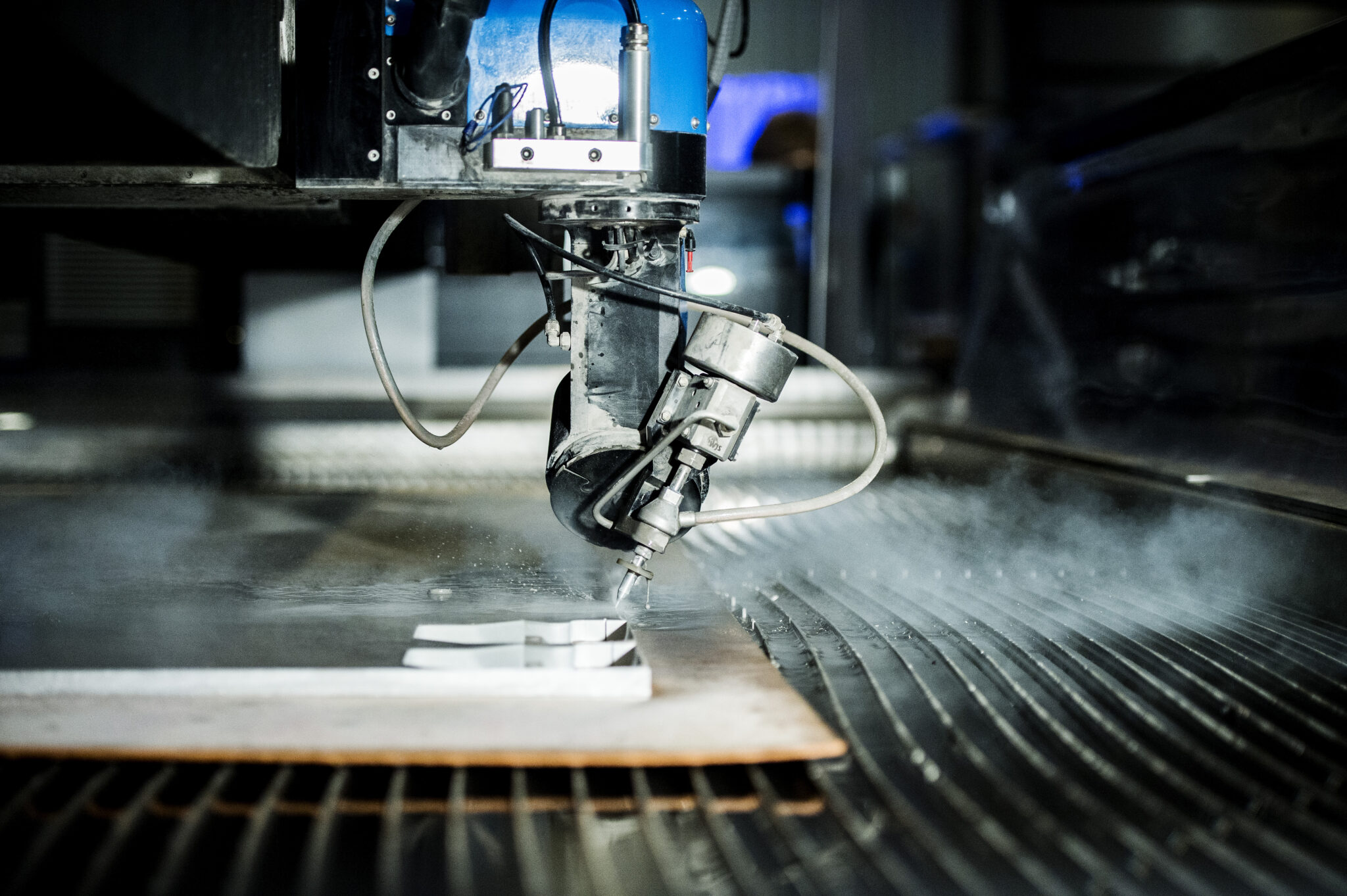

At Charles Day Steels, we are excited to offer our state-of-the-art waterjet bevel cutting services, bringing you unmatched precision and versatility. Our investment in the revolutionary Waterjet Sweden Beveljet 60 cutting head and 125hp pump positions us at the forefront of the metal profiling industry, delivering top-tier quality and performance.

Why Choose Water Bevel Cutting?

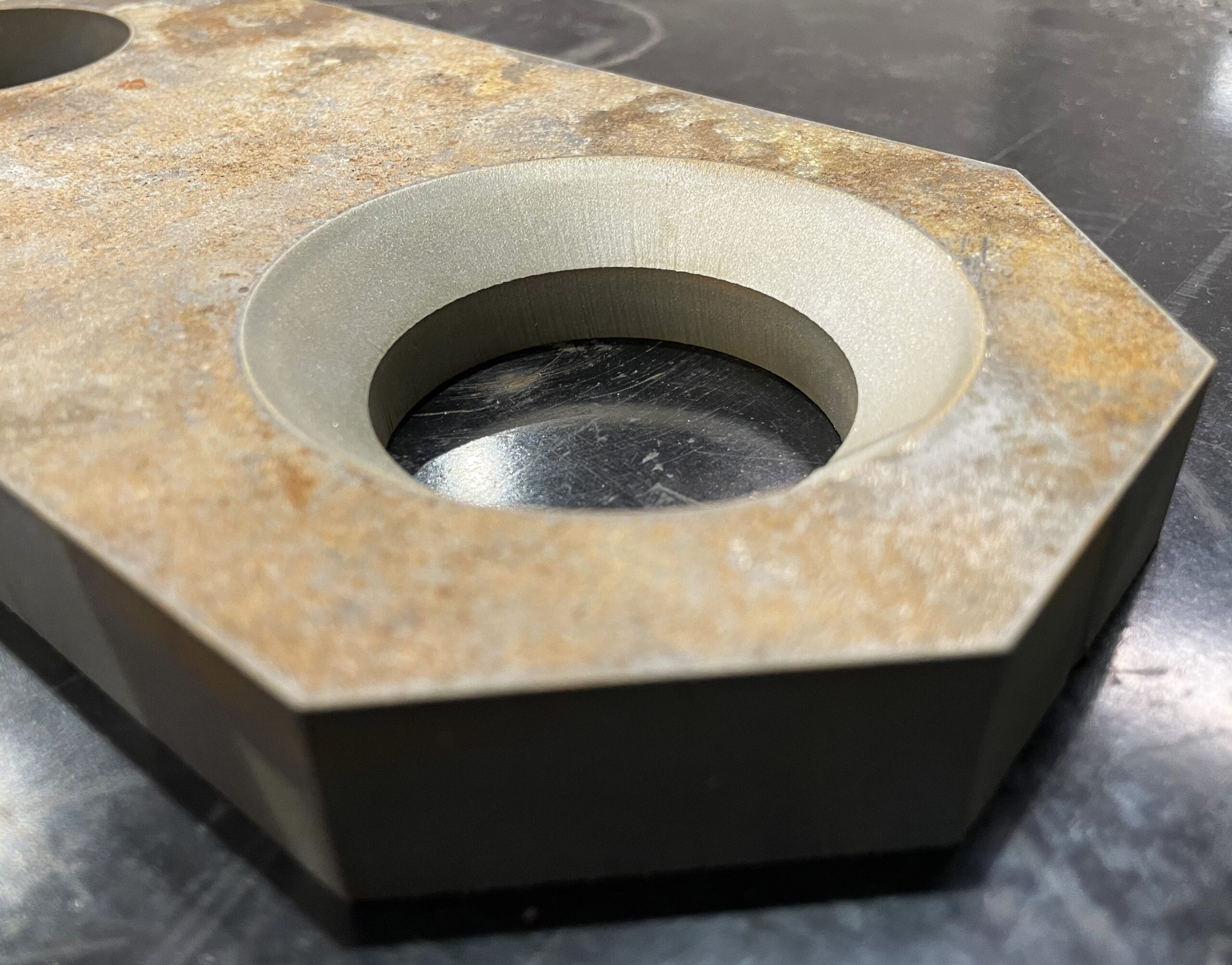

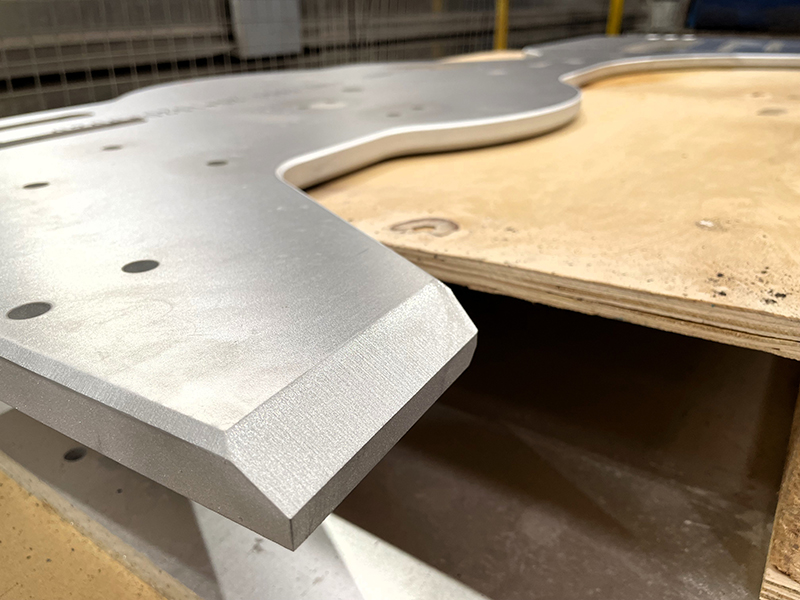

Waterjet bevel cutting is an efficient and economical method, ideal for large-scale production with tight lead times. It delivers precise cuts with an accuracy of ±0.25mm and eliminates the need for grinding, making it a superior alternative to conventional cutting techniques.

Harness the Power of Water Bevel Cutting

Our water bevel cutting services are engineered to tackle the most intricate cuts with remarkable accuracy and efficiency. Some benefits include:

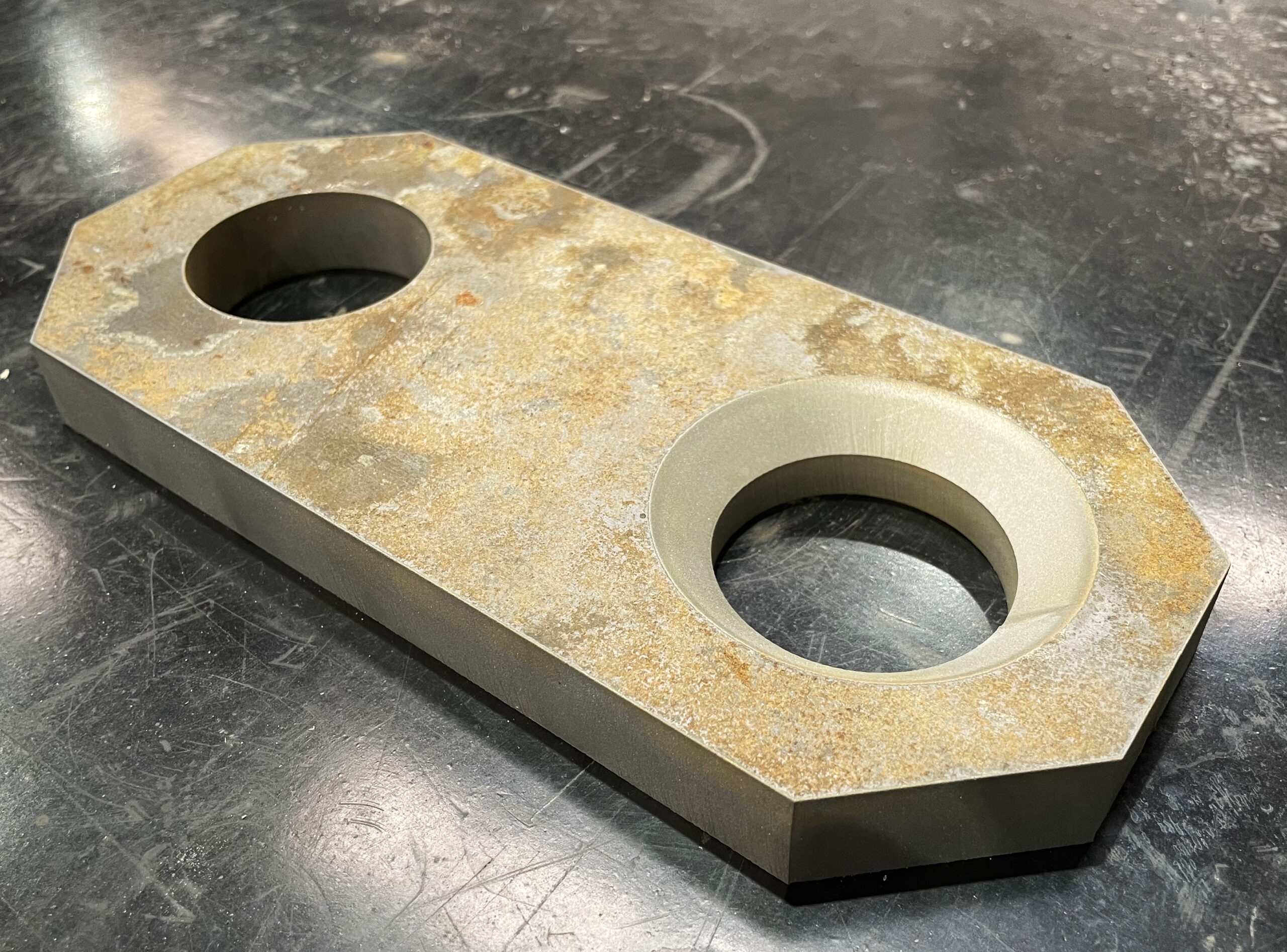

Flexible Cutting Angles

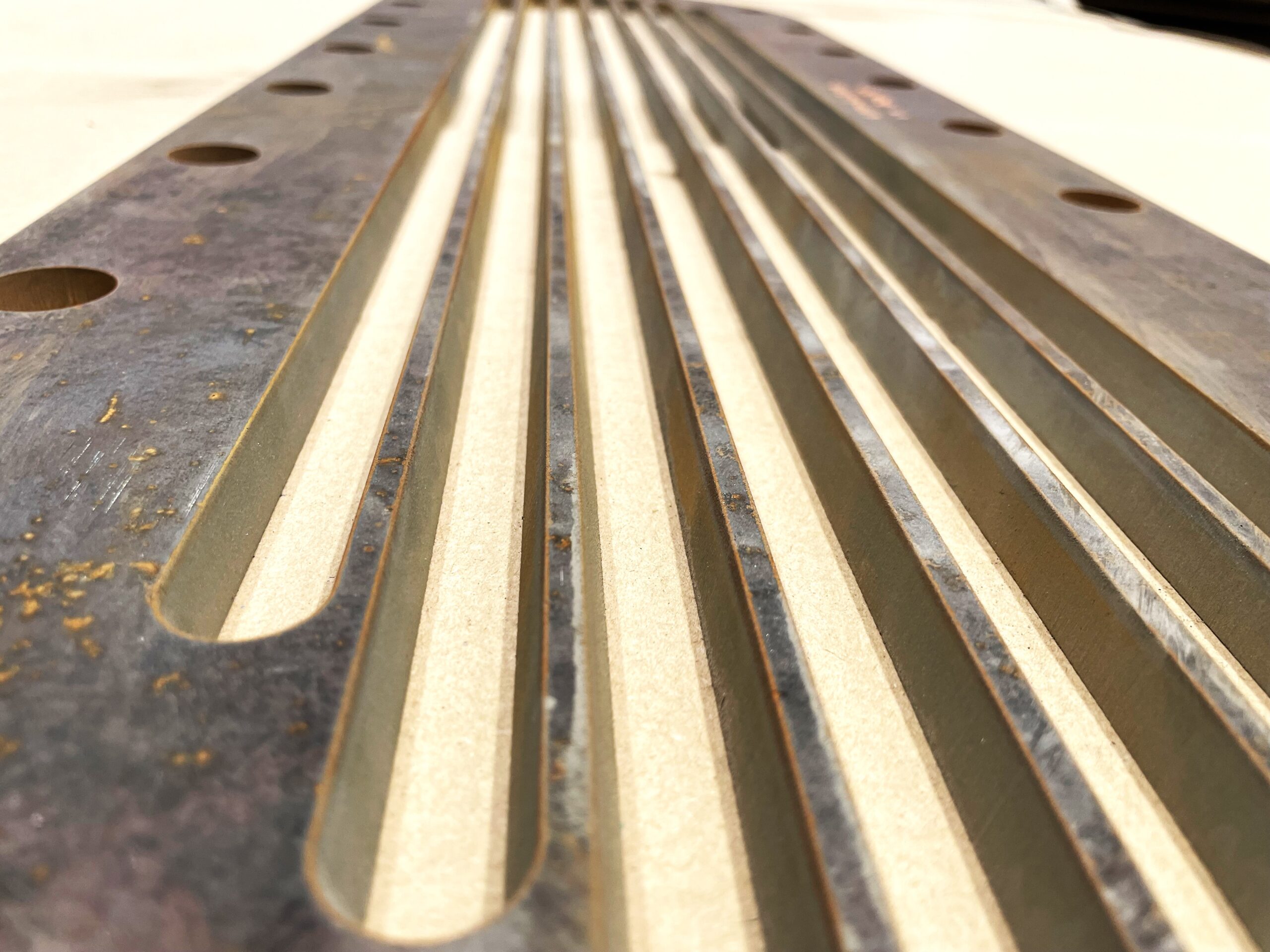

Capable of processing materials at angles up to 60 degrees, our waterjet technology handles a range of materials including mild steel, alloys, and stainless steel. This flexibility reduces the need for secondary operations like machining, saving you time and resources.

Exceptional Power and Precision

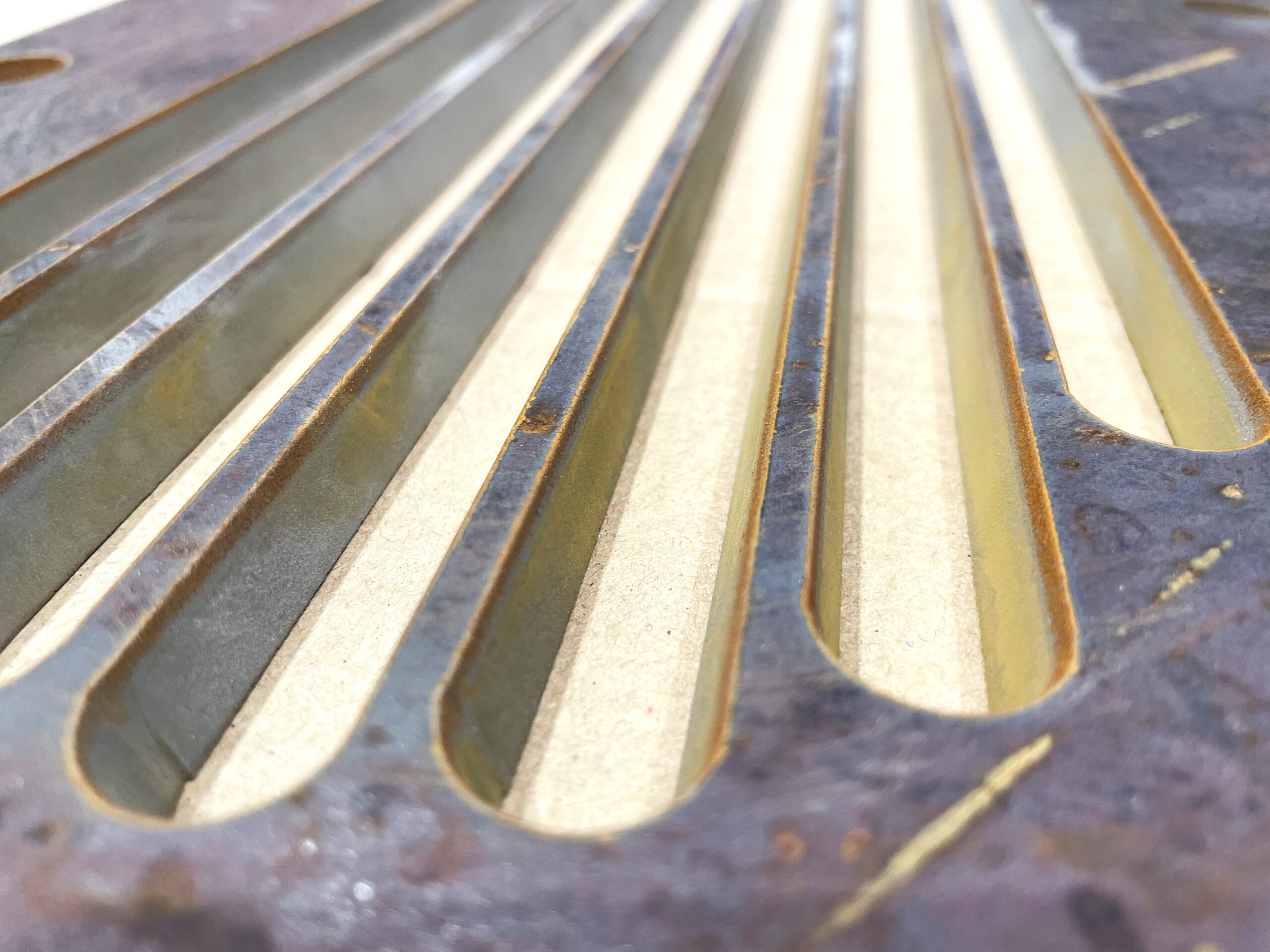

The Waterjet Sweden Beveljet 60’s 125hp pump delivers an impressive 6,200 bar of pressure, ensuring precise cuts across various material thicknesses with unparalleled accuracy.

Dual Cutting Heads

The innovative dual-head design allows for simultaneous 3D and 2D cutting, enhancing productivity and reducing production times.

Benefits of Our Waterjet Bevel Cutting Services

Opting for Charles Day Steels for your waterjet bevel cutting requirements comes with significant benefits:

Precision Guaranteed

Our automated systems ensure high precision with zero margins for error, providing consistent and accurate results every time.

Streamlined Fabrication Process

Our advanced waterjet technology minimises the need for post-processing, offering you parts that are ready for immediate assembly, thus reducing overall project time and costs.

Rapid Turnaround

Operating around the clock, we ensure quick and efficient delivery without sacrificing quality, even for large-scale and complex projects.

Cost Efficiency

By eliminating additional weld preparation steps, we offer a cost-effective solution that translates into savings for our customers.

Comparing Waterjet Bevel Cutting to Laser Bevel Cutting

We also provide laser bevel cutting services to address a broader range of materials and project requirements. Here’s a comparison of the two methods:

Waterjet Bevel Cutting

- Best suited for thicker materials (up to 270mm)

- Uses a cold-cutting process, ideal for heat-sensitive applications

- Ensures accuracy to ±0.25mm

- Features multi-head cutting for enhanced productivity

Laser Bevel Cutting

- Highly efficient and cost-effective

- Provides precise cuts to ±0.25mm

- Ideal for high-volume production

- Offers quick turnaround without post-cutting grinding

Contact Us Today

Explore the potential of waterjet bevel cutting with Charles Day Steels. Reach out for a free quote and learn how our advanced services can benefit your next project.

For more information about our Water Bevel Cutting services and to discuss your project requirements, click here to get in touch.

Water Bevel Cutting FAQs

What is water bevel cutting?

Water bevel cutting is a precise cutting method that uses high-pressure water jets mixed with abrasive materials to cut and shape materials at various angles. This technique is commonly used to create bevelled edges on materials like metal, glass, stone, and composites.

What materials can be cut using water bevel cutting?

Water bevel cutting is versatile and can be used on a wide range of materials, including metals (such as steel, aluminium, and titanium), glass, ceramics, stone, composites, and even some plastics.

What are the advantages of water bevel cutting compared to other cutting methods?

Water bevel cutting offers several advantages:

- Precision: High accuracy and detailed cuts.

- No Heat-Affected Zones: Unlike laser or plasma cutting, it doesn’t produce heat, which can alter material properties.

- Versatility: Can cut various materials and thicknesses.

- Environmentally Friendly: Uses water and natural abrasives, reducing hazardous waste.

What are the typical applications of water bevel cutting?

Common applications include:

- Architectural Components: Creating decorative edges and precise cuts in building materials.

- Industrial Manufacturing: Cutting parts for machinery and equipment.

- Automotive: Shaping and cutting components for vehicles.

- Aerospace: Precision cutting for aircraft parts.

- Art and Design: Crafting intricate designs in various materials.

How does water bevel cutting work?

Water bevel cutting uses a high-pressure water jet, often mixed with an abrasive substance like garnet, to erode material along a specified path. The water jet can be angled to create bevel cuts, allowing for precise control over the angle and shape of the cut edge.