Mild Steel Laser Cutting Services: Efficient and Reliable Profiling

An efficient and reliable material, mild steel is a popular choice for laser cutting due to its versatility and robustness. Laser cut mild steel has been the prime choice of many of our customers since we installed our first sub-contract laser cutting machine back in 1999. Laser cutting mild steels is preferred to other methods as it offers excellent cut edge quality, short lead times and is considered more economical when compared to other profiling methods.

Over the years we have profiled all grades of this versatile metal for numerous industries from creative design to structural steelworkers. Our state-of-the-art laser cutting facilities can easily handle a full range of carbon and mild steels in thicknesses up to 50mm and sheet sizes to 6m x 2.5m. Running 24 hours a day, our suite of laser cutting machines can easily handle virtually any requirement.

We keep popular thicknesses and sheet/plate sizes in stock and commonly cut thicknesses from 0.25mm up to 20mm. However, if we don’t have your desired material or thickness available, we can usually source it within 48 hours. We can also laser cut your free-issue steel, and test certificates can be supplied when requested.

If you require laser cut carbon steel profiles, contact our experienced Sales Team today for further help and guidance.

Why Choose Charles Day Steels for Mild Steel Cutting?

With over four decades of metal profiling expertise, we here at Charles Day Steels take immense pride in being one of the UK’s leading metal profiling companies. Equipped with some of the best mild steel cutting facilities available in the industry, our commitment to continuous self-reinvestment is underscored by our comprehensive series of in-house metal profiling facilities; always going the extra mile to provide our customers with an efficient, reliable and professional service every time.

Our dedication to quality assurance, commitment to diverse cutting and profiling capabilities, 24-hour production, extensive range of metals in varying sizes and thicknesses, and competitive pricing, exemplify our commitment to excellence.

THE ALL-IN-ONE

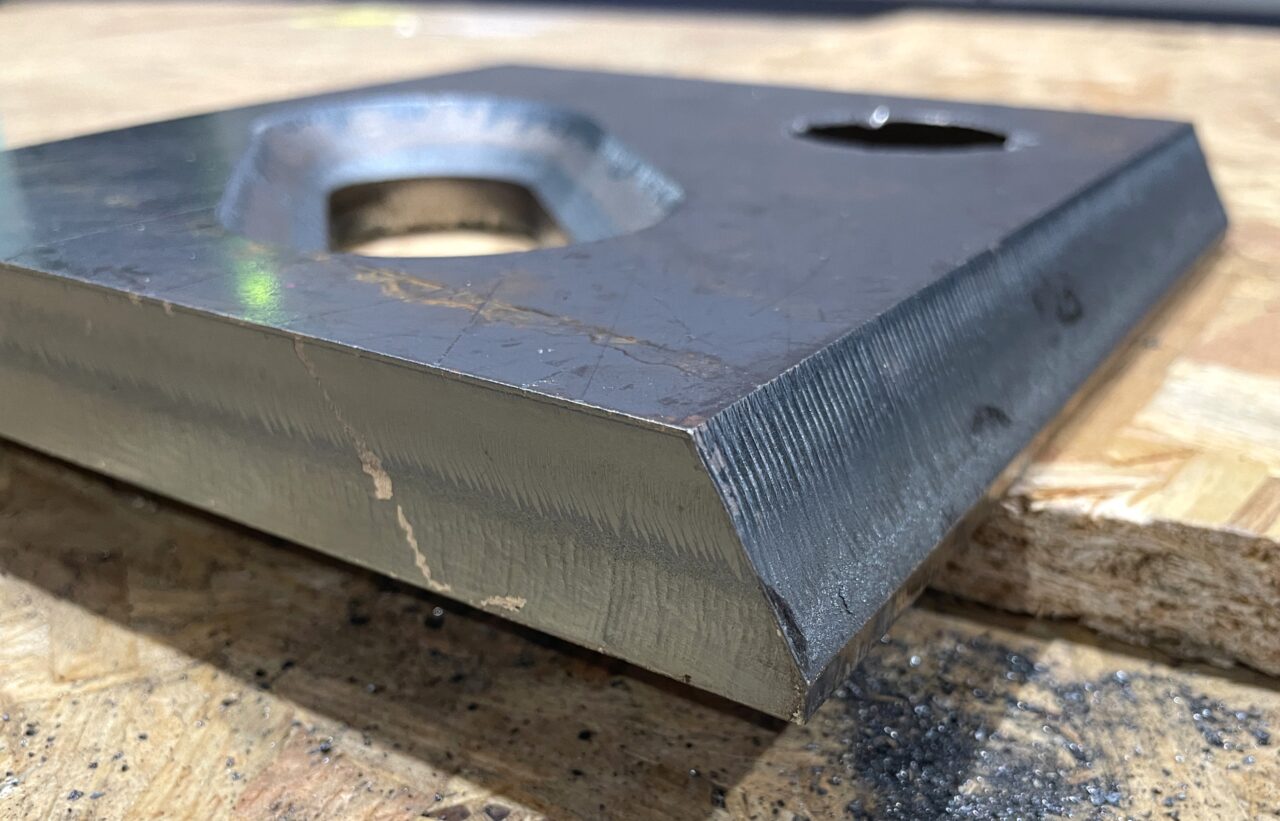

Boost Efficiency with Laser Bevel Cutting!

Save time and reduce costs with our advanced 50-degree Laser Bevel Cutting. Get fabrication-ready parts with built-in weld preps, eliminating manual grinding and speeding up assembly. Stronger joints, faster turnaround, lower costs.

Benefits of Laser Cut Mild Steel by Charles Day Steels

Laser cutting aluminium steel offers a diverse array of benefits, from cost-effectiveness to versatility, aluminium cutting is the preferred material across various industries for its robust nature and light weight. Some of the key advantages of laser cut aluminium include:

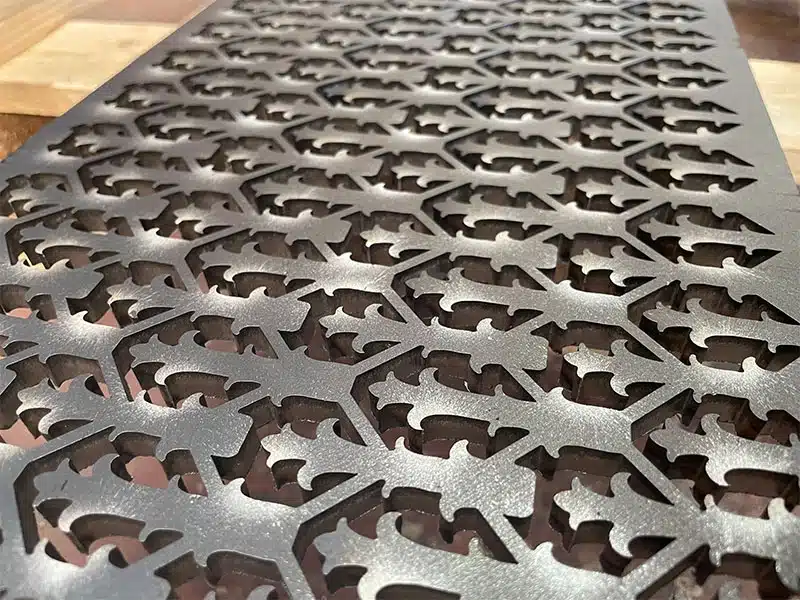

Precision Cutting

Mild steel can be cut with high precision and accuracy, allowing for intricate and complex designs to be cut with minimal error

Versatility

Mild steel is highly versatile and can be easily fabricated into different shapes and sizes, making it suitable for various applications, and providing flexibility in design and construction.

Clean Cuts

Laser cutting produces clean, smooth edges without the need for secondary finishing processes, reducing the need for additional machining or deburring. This helps save time and labour costs.

Affordability

Mild steel is relatively inexpensive compared to other metals, making it a cost-effective choice for many applications; making it accessible for a wide range of projects and industries.

Minimal Material Waste

Laser cutting minimises material waste due to its precision cutting capabilities. This helps optimise material usage and reduce costs associated with material scrap.

Non-contact Cutting

Laser cutting is a non-contact process, which means there is no direct mechanical force applied to the material. This reduces the risk of material distortion or damage.

Typical Mild Steel Cutting Applications

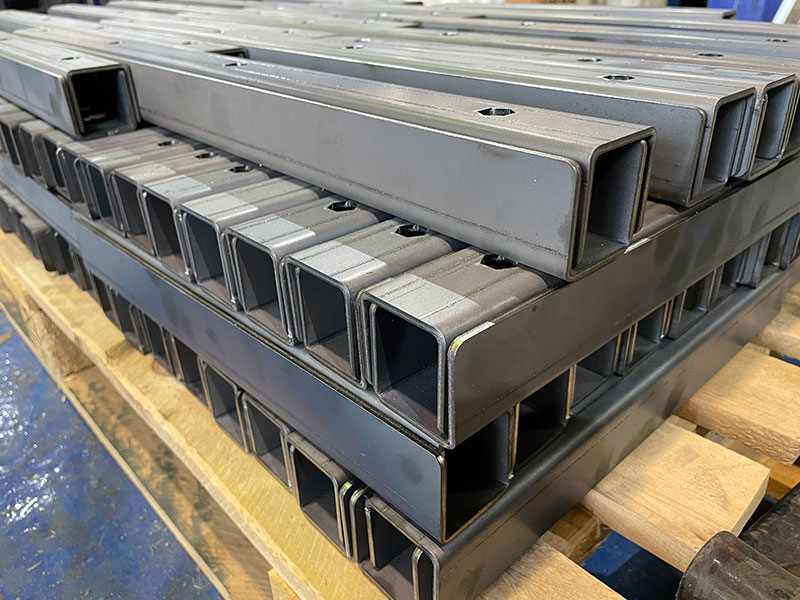

Mild steel cutting finds applications across a broad spectrum of industries due to its versatility and durability. Mild steel profiling makes up a large percentage of what we cut here at Charles Day, for this reason, we get involved with a whole spectrum of industries; including, but not limited to:

- Structural Fabrication & Components (beams, columns, frames)

- Automotive Manufacturing (chassis, body panels, frames)

- Machinery and Equipment (gears, shafts, brackets)

- General/Architectural Fabrication (gates, fences, railings)

- Agricultural Equipment (plows, cultivators, trailers)

- Storage Tanks and Containers (storage tanks, containers, silos)

- Furniture Manufacturing (furniture frames, shelves, and other structural components)

- Refuse & Recycling (waste compactors & crushers)

- Creative Industries (artwork, sculptures etc)

Sheet Metal Laser Cutting Thicknesses

With a plethora of in-house laser cutting capabilities, we can laser cut sheet metal in a variety of thicknesses depending on the material selected.

Laser Cut Thickness (mm)

Steel Contamination Prevention Measures

At Charles Day Steels, we understand the importance of maintaining the integrity of materials to prevent contamination and subsequent rusting. Stainless steel can be susceptible to contamination by mild steel, which compromises its corrosion-resistant properties.

To mitigate this risk, we implement rigorous measures:

Segregated Storage

We store mild steel separately from stainless steel to avoid any potential contact and subsequent contamination.

Specialised Cutting Surfaces

Our cutting facilities utilise stainless steel bed slats instead of mild steel slats. This prevents any splatter from mild steel during the cutting process, reducing the risk of contamination.

By implementing these measures, we ensure that our laser cutting services uphold the highest standards of quality and reliability, safeguarding the purity of steel materials and meeting the stringent requirements of our customers.

Mild Steel Cutting Grades and Capabilities

Mild Steel Laser Cutting Capabilities

Maximum Cutting Size

6m x 2.5m (6000mm x 2500mm) – Larger sheet sizes can be handled by our waterjet, flame and plasma machines.

Maximum Material Thickness

50mm

Minimum Material Thickness

0.25mm (Depending on material)

Complex Details

Our CNC laser machines are incredibly accurate and can easily process the most complex and intricate profiles (Thickness of steel may impact certain details).

Cutting Tolerances

View our laser cutting tolerances here.

Cutting Edge Quality

We can achieve a good edge quality when we laser cut mild steel up to 20mm thick. (As the thickness increases the striations on the cut-edge become more prominent.)

Mild Steel Cutting Grades

We’re able to laser cut aluminium plates and sheets in all grades as well as numerous aluminium alloys. Some of the more common grades we get asked to cut include:

- S275

- S355

- CR4 – Cold Reduce

- EN8

- 400 Wearplate / 400 Brinell

- S690QL High Yield

- Weathering Steel / COR-TEN

- Galvanised

- Tool Steel

- Durbar/Floor Plate