Sustainable Precision Laser Cutting

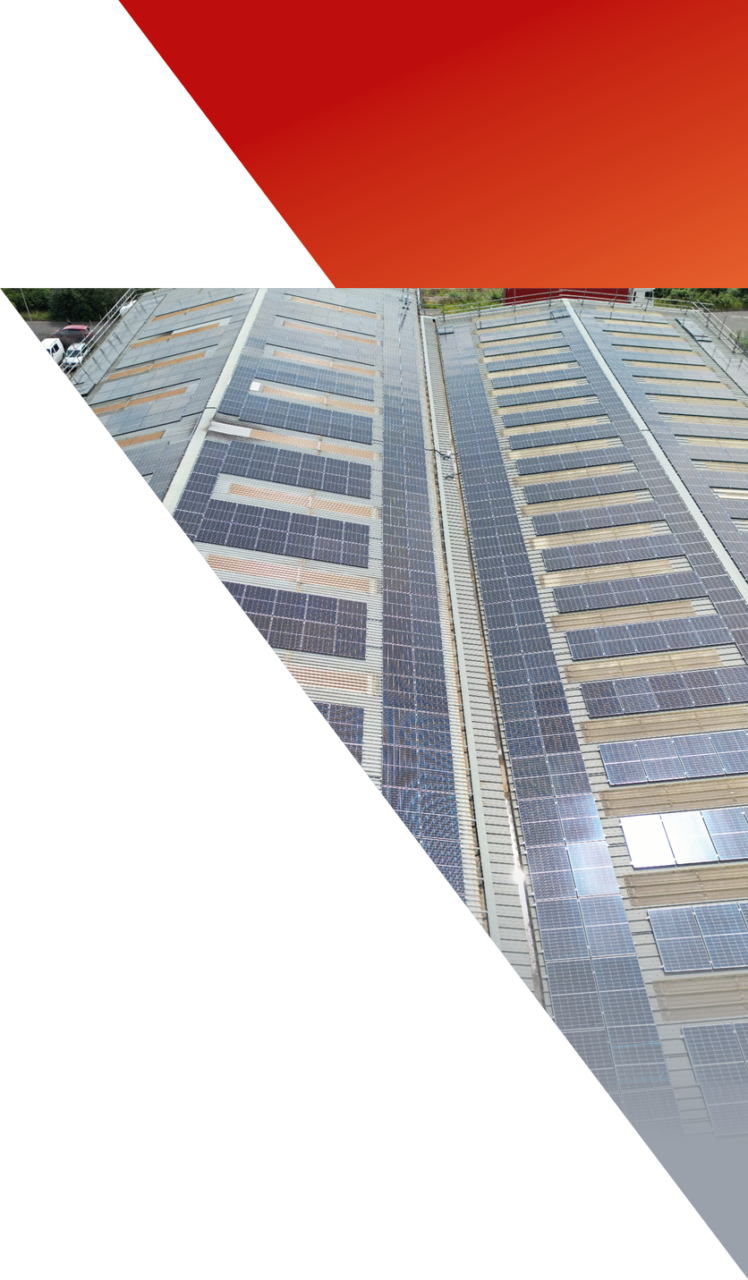

Charles Day Steels offers industry-leading laser cutting with seven state-of-the-art machines, including the UK’s first 20kW fibre laser, ensuring short lead times and high-quality results. Our expertise encompasses tube, sheet metal, and structural steel cutting, handling projects of all sizes. We also prioritise sustainability, with solar-powered facilities and electric forklifts which has contributed to us achieving ISO 14001:2015 accreditation.

Materials we cut

-

Stainless steel

50mm

-

Steel

50mm

-

Aluminium

40mm

-

Brass & Copper

20mm

-

Titanium

10mm

Key Benefits

Handle metal sheet sizes up to 6510mm x 2600mm cutting bed

Metal cutting up to 50mm thick

Operating to ISO 9001 and CE Marking BS/EN 1090- 1 (level 4), we are proud to provide a second to none service.

Full capacity running 24/7

Large in-house stock providing shorter lead times and competitive prices.

Sustainable profiling with full-site solar-powered services

Fast and accurate cutting

Heavy gauge pressing up to 4300mm

Unrivalled cutting capability

Request a free no-obligation quote

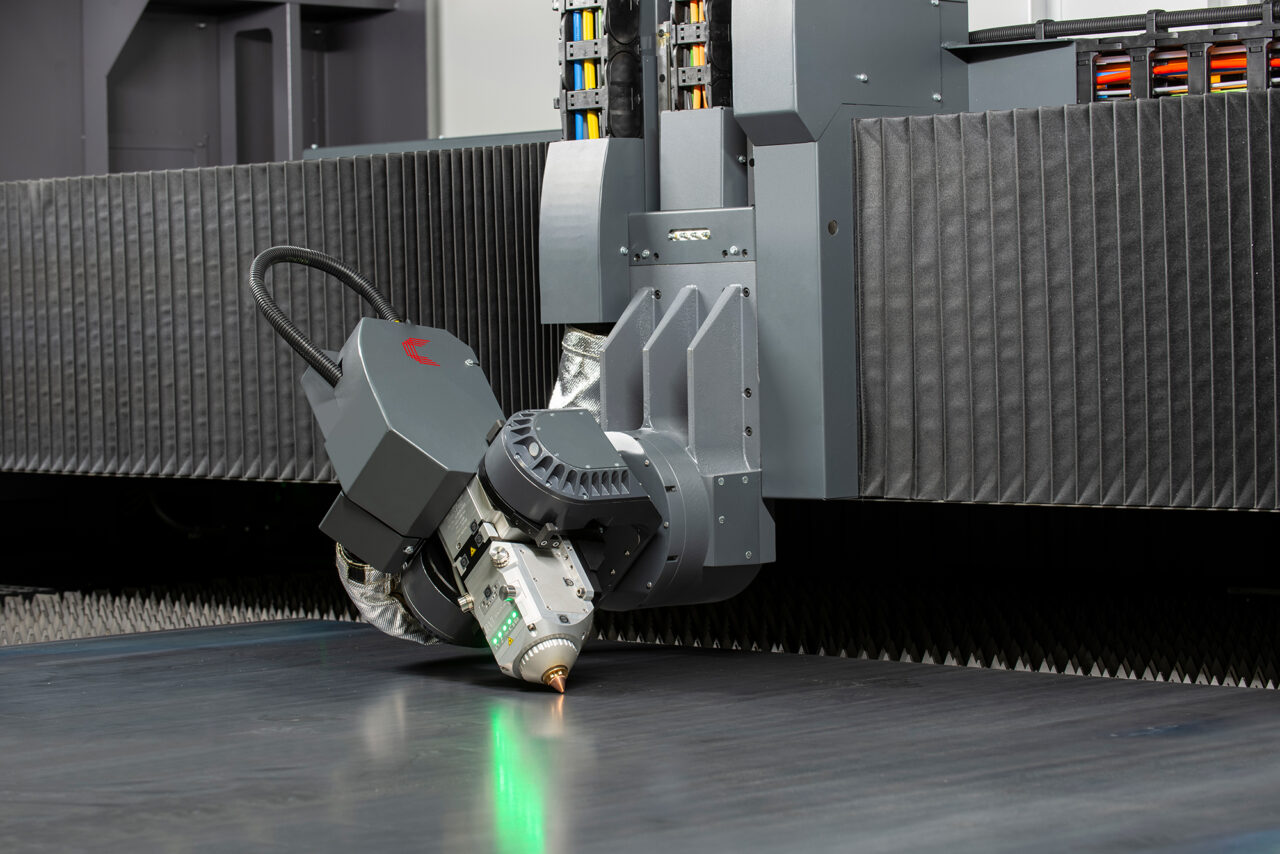

Our in-house Laser cutting services

- Fibre laser cutting

- Sheet metal laser cutting

- Tube laser cutting (3D cutting)

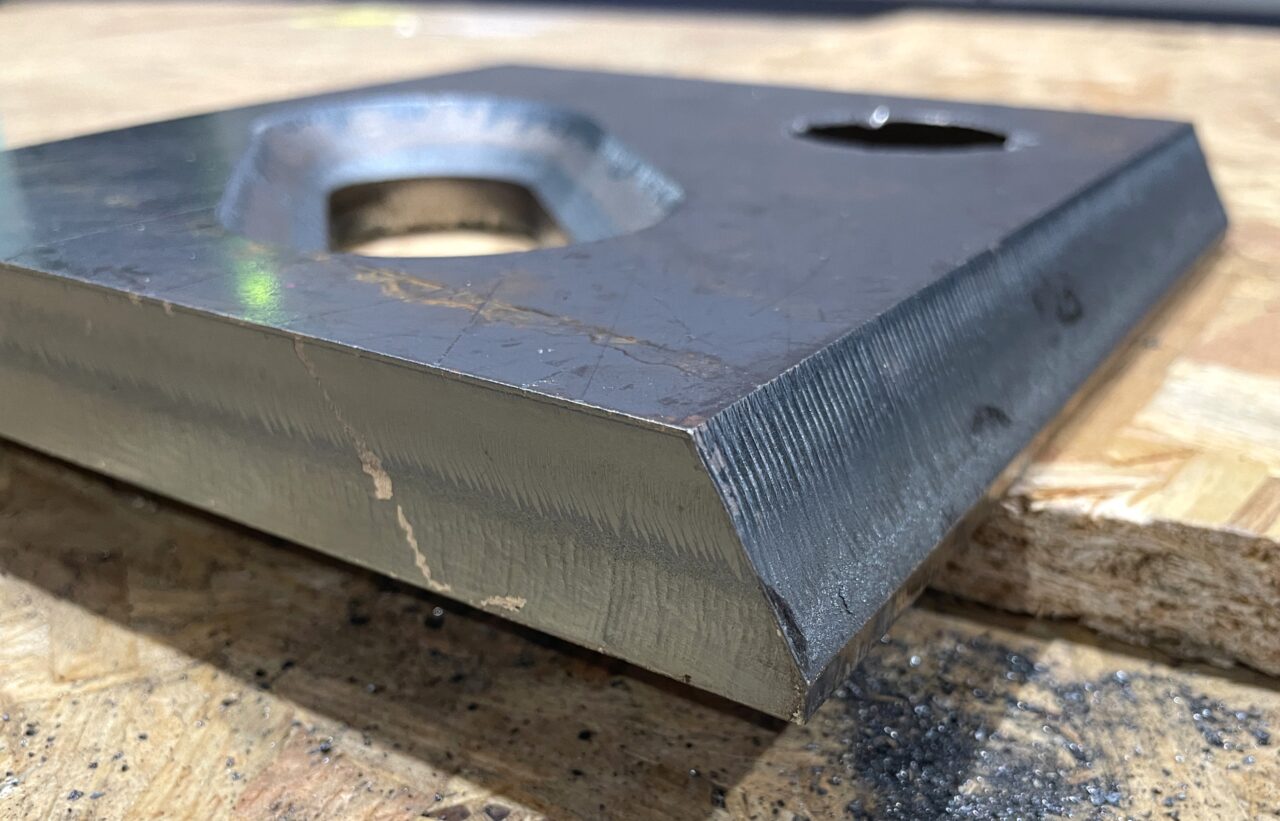

- Bevel and countersink

- Large and open section cutting

- Flow drilling and tapping

Why Charles Day?

Experience

With 45+ years at the forefront of specialist cutting, we make procurement easy.

Service

We make procurement easy with simple and transparent custom service and years of industry expertise. Your parts are our priority.

Environmental Initiatives

Fully ISO 14001 accredited we are committed to making your power supply chain greener with solar laser power.

Capacity and Reliability

Operating the UK's largest capacity 24/7 across all services, we guarantee short lead times for projects of all sizes.

Quality

Operating to ISO 9001 and CE Marking BS/EN 1090-1 EXC4, we are proud to provide a second to none service.

THE ALL-IN-ONE

Boost Efficiency with Laser Bevel Cutting!

Save time and reduce costs with our advanced 50-degree Laser Bevel Cutting. Get fabrication-ready parts with built-in weld preps, eliminating manual grinding and speeding up assembly. Stronger joints, faster turnaround, lower costs.

Laser Cutting FAQs

How Does Laser Cutting Work?

Laser cutting is a non-contact process that uses a high-powered focused beam to rapidly heat the material and create thermal separation. It is applicable to various materials and projects and offers meticulous tolerances and complex designs.

What Are the Capabilities of Laser Cutting?

Laser cutting ensures precise results across diverse metal profiling and finishing services. Capable of conducting tube laser cutting, sheet metal laser cutting, structural steel open-section cutting, and many more projects, regardless of scale and complexity.

What is the Maximum Thickness That Laser Can Cut?

Our laser cutting machines can cut sheet metal across various thicknesses with a profiling tolerance between +/- 0.12mm to +/- 0.75mm. Typical metal cutting abilities include:

- Steel – 50mm

- Stainless Steel – 50mm

- Aluminium – 40mm

- Brass – 20mm

- Copper – 20mm

How Precise is Laser Cutting?

Our laser cutting services offer high precision; with tolerances between +/-0.12mm and +/-0.25mm (depending on material thickness). This level of accuracy makes it suitable for intricate designs and precise cutting requirements.

What Does Kerf Mean in Laser Cutting?

Kerf is the result of how much material is removed during the laser cutting process and the measurement of the width between each cut. Although this typically has a minuscule impact, it’s imperative to consider kerf laser cutting across the overall dimension of your project.

How Long Does Laser Cutting Take?

Fibre laser cutting provides rapid results, handling sheet sizes up to 6m x 2.5m with the ability to pre-program cutting paths, ensuring consistency across the project. Charles Day Steels operates 7 fibre laser machines 24 hours a day, 7 days a week.

How is laser cutting quality ensured?

Charles Day Steels ensures quality through efficient machine setup and frequent maintenance. Our team takes special care to adhere to stringent operating parameters relevant to the material and desired outcome. Additionally, we conduct regular visual and dimensional inspections throughout the production process, whilst ensuring we maintain BS/EN IS0 9001:2015 Quality Accreditation.

What materials can be laser cut?

Our in-house capabilities mean that we can cut and process a spectrum of materials, including stainless steel, mild steel, aluminium, copper, brass, bronze and titanium.

What is the difference between laser and waterjet cutting?

Waterjet cutting utilises a high-pressure stream of water that is combined with an abrasive medium to cut through material without the use of heat. Also known as a cold-cutting process, waterjet cutting is perfect for heat-sensitive materials. Alternatively, laser cutting generates heat to create clean edges, minimal post-processing and rapid lead times for a large majority of metals.

How can I get a quote for laser cutting services?

You can request a quote for our laser cutting services by contacting us directly with your project details, including material type, thickness, and design specifications. Get in touch with Charles Day Steels today and our team will provide a detailed and competitive quote.