Charles Day Limited of Sheffield, a long established specialist profiling and cutting operation with multi-installation laser cutting and flame cutting facilities, has recently placed an order with WJS (Water Jet Sweden) for a multi head water jet cutting machine with a cutting bed of 8m x 4m. The new machine will offer the UK’s largest subcontract water jet cutting bed with multi head cutting.

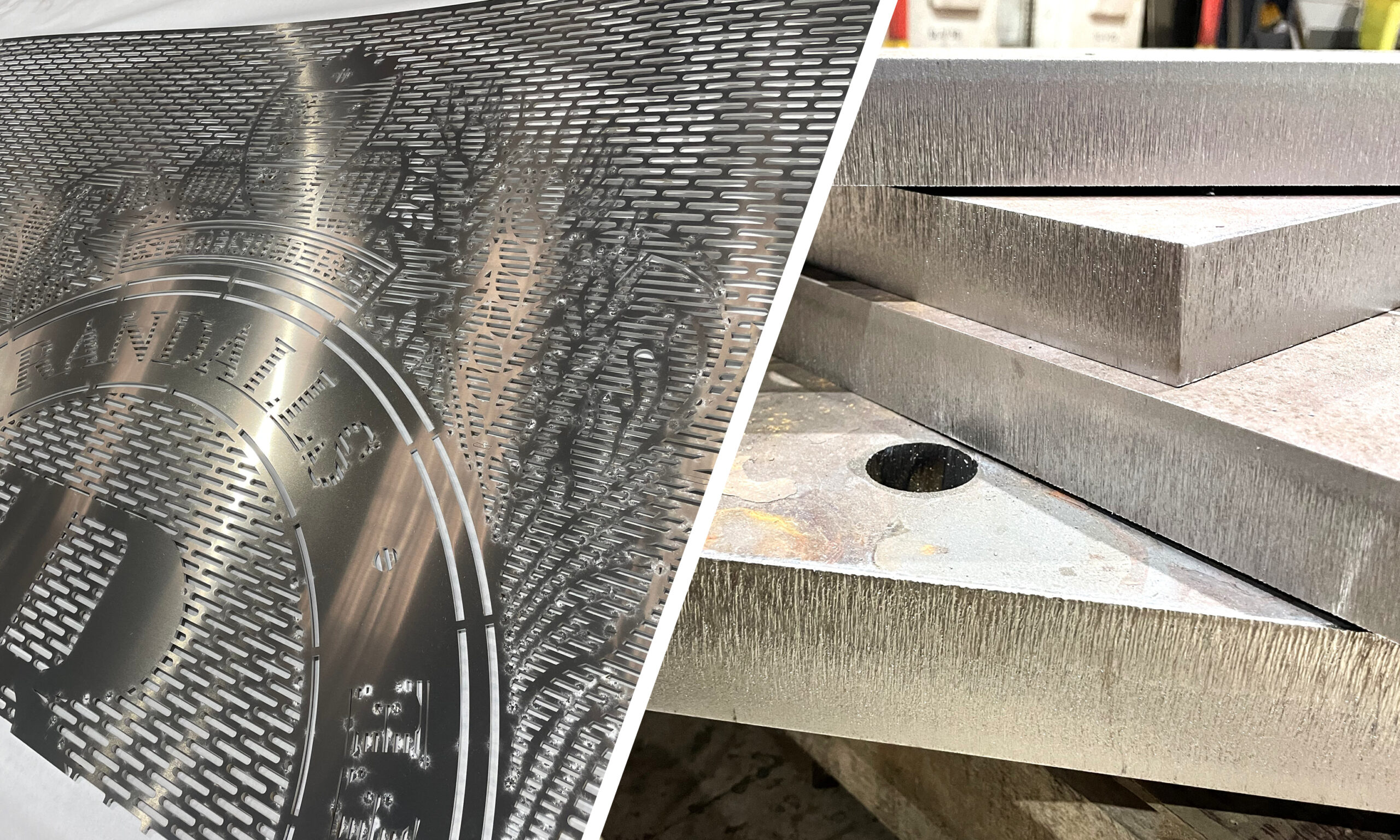

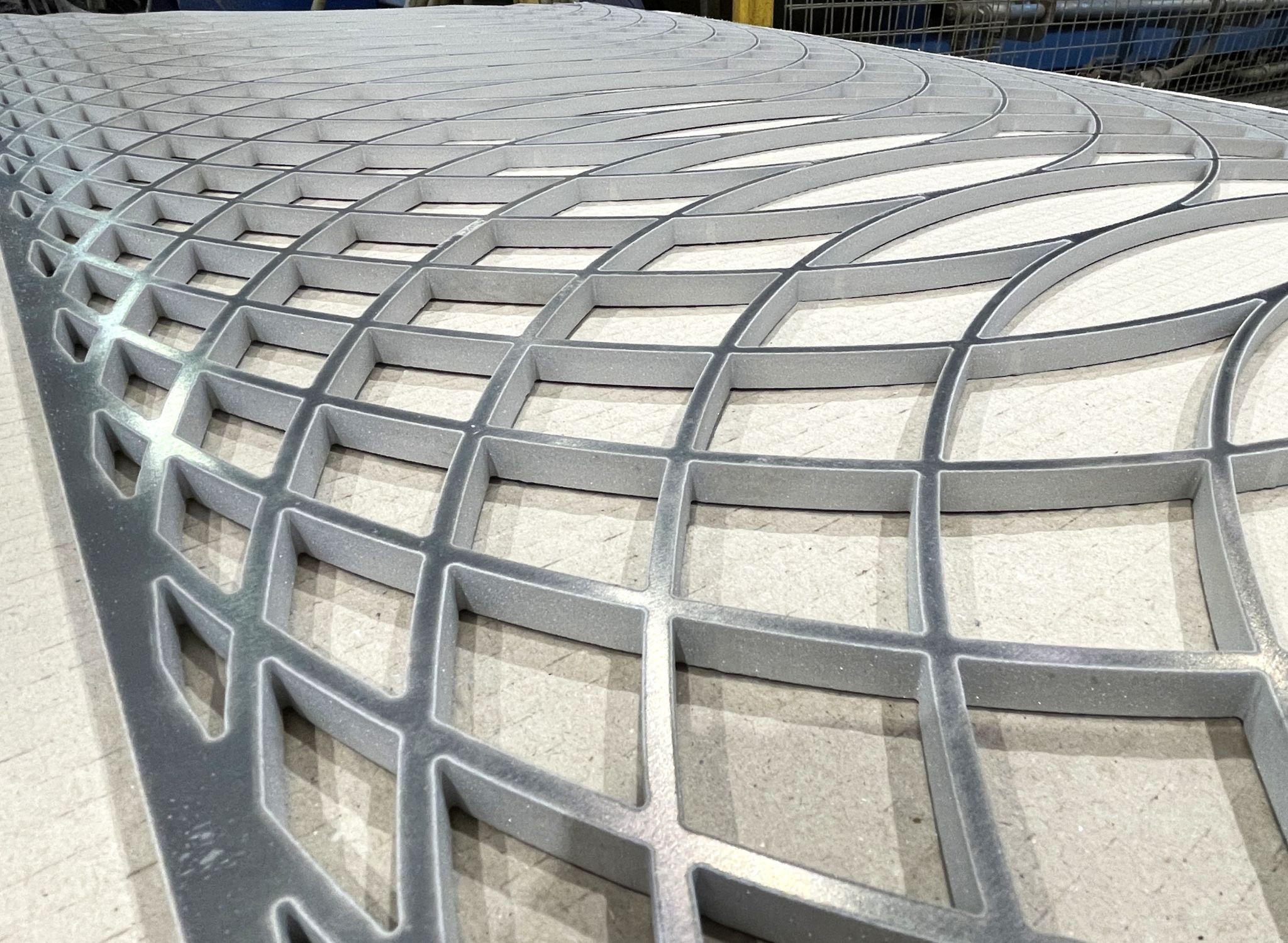

Now one of the fastest growing precision profile production methods world wide, water jet cutting has the advantage of cutting thicker aluminum and stainless steel in addition to a huge variety of engineering materials, with no heat-effected edges, compared to laser and flame cutting.

The new WJS water jet equipment not only allows Charles Day to offer its traditional engineering customers an alternative cutting technology, but also allows the company to apply its profiling skills to new materials and new markets. These advanced machines can cut glass, ceramics, rubber, wood, and plastics.

Charles Day has continued to invest in its quality control and in-house programming. Virtec Laser QC measuring systems ensure that complete dimensional checks against drawings are made for each component with batch inspection of finished components monitored through the system. An added advantage is that Laser QC can also reverse engineer components where there are no drawings.