Bevel Cutting Applications in Aerospace Engineering

The aerospace industry, known for its high standards and precision requirements, often turns to advanced cutting techniques to meet its unique needs. One such technique, bevel cutting, plays a crucial role in manufacturing and assembling components with intricate designs and demanding tolerances.

What is Bevel Cutting?

Bevel cutting involves cutting the edges of a material at an angle other than 90 degrees. This technique is used to prepare parts for welding, reduce the need for additional machining and improve the fit and finish of components. In aerospace engineering, bevel cutting is employed to achieve precise and clean cuts on various materials, including metals like aluminium, stainless steel and titanium.

Bevel Cutting Techniques and Technologies

Several cutting technologies are used for bevel cutting, each offering unique advantages:

Laser Bevel Cutting

Precision and Speed

Laser bevel cutting provides high precision and speed, making it ideal for cutting thin to moderately thick materials with minimal heat-affected zones (HAZ). The automated process ensures consistent quality and reduces the need for post-processing.

Applications

Used for cutting intricate shapes and contours in aerospace components such as brackets, mounts and structural parts.

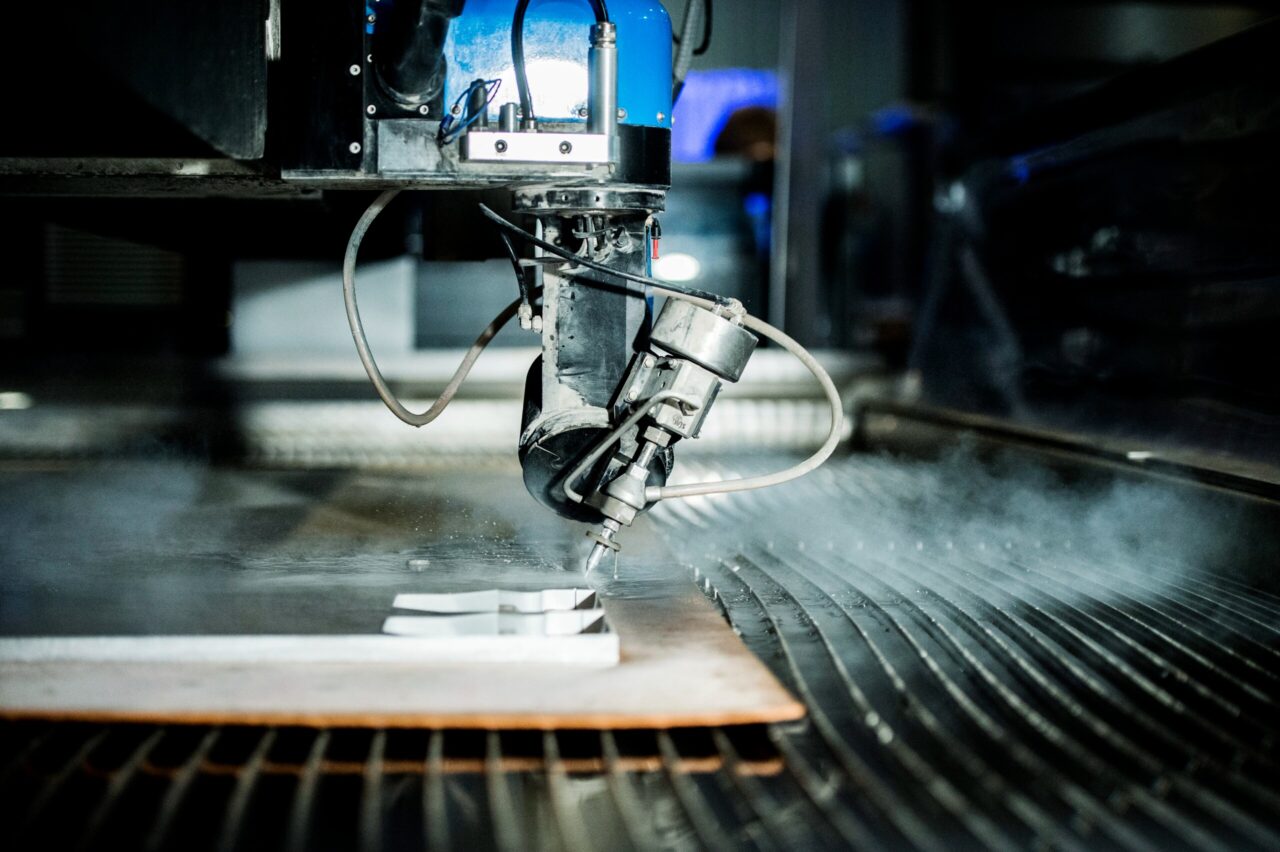

Waterjet Bevel Cutting

Versatility

Waterjet bevel cutting can handle a wide range of materials and thicknesses, from metals to composites, without introducing thermal stress. The ability to cut at angles up to 60 degrees enhances its versatility.

Applications

Ideal for cutting complex parts where precision and material integrity are critical, such as turbine blades, engine components and composite panels.

Key Bevel Cutting Applications in Aerospace Engineering

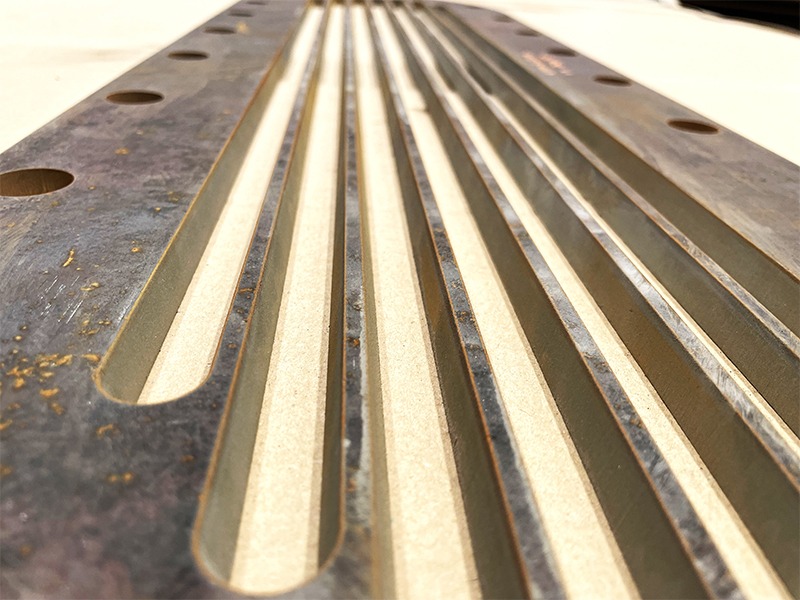

Welding Preparation

Bevelled Edges for Strong Welds

Bevel cutting prepares the edges of metal sheets and plates for welding, ensuring a strong and clean weld joint. This is crucial in aerospace manufacturing, where weld integrity affects the overall safety and performance of the aircraft.

Assembly of Complex Structures

Precision Fit

Aerospace components often have complex geometries that require precise fitting during assembly. Bevel cutting ensures that parts fit together perfectly, reducing gaps and enhancing structural integrity.

Reduction of Post-Processing

Minimised Machining Needs

By using bevel cutting, manufacturers can reduce the need for additional machining processes. This not only saves time but also minimises material wastage and production costs.

Improving Aerodynamics

Streamlined Designs

Bevel cutting allows for the creation of streamlined edges and surfaces, which can improve the aerodynamic performance of aircraft components. This is particularly important for parts exposed to airflow, such as wings and fuselage sections.

Component Lightweighting

Efficient Material Use

Bevel cutting can be used to remove excess material without compromising the strength of the component. This is essential for aerospace applications, where reducing weight can lead to significant improvements in fuel efficiency and payload capacity.

Advantages of Bevel Cutting in Aerospace

High Precision

Bevel cutting technologies, especially laser and waterjet, offer high precision, ensuring that components meet strict aerospace standards.

Material Versatility

The ability to cut various materials, including metals and composites, makes bevel cutting adaptable to different aerospace applications.

Enhanced Strength

Properly bevelled edges contribute to stronger welds and joints, enhancing the overall structural integrity of the aircraft.

Cost Efficiency

By reducing the need for additional machining and minimising material waste, bevel cutting contributes to cost savings in the manufacturing process.

Trust Charles Day Steels for Professional Bevel Cutting for Aerospace Applications

Bevel cutting is a vital technique in aerospace engineering, enabling the production of high-precision, high-strength components essential for modern aircraft. With advancements in cutting technologies like laser cutting and waterjet cutting, the aerospace industry can achieve greater efficiency, accuracy and performance.

For further information and guidance regarding our bevel cutting capabilities, contact Charles Day Steels today.