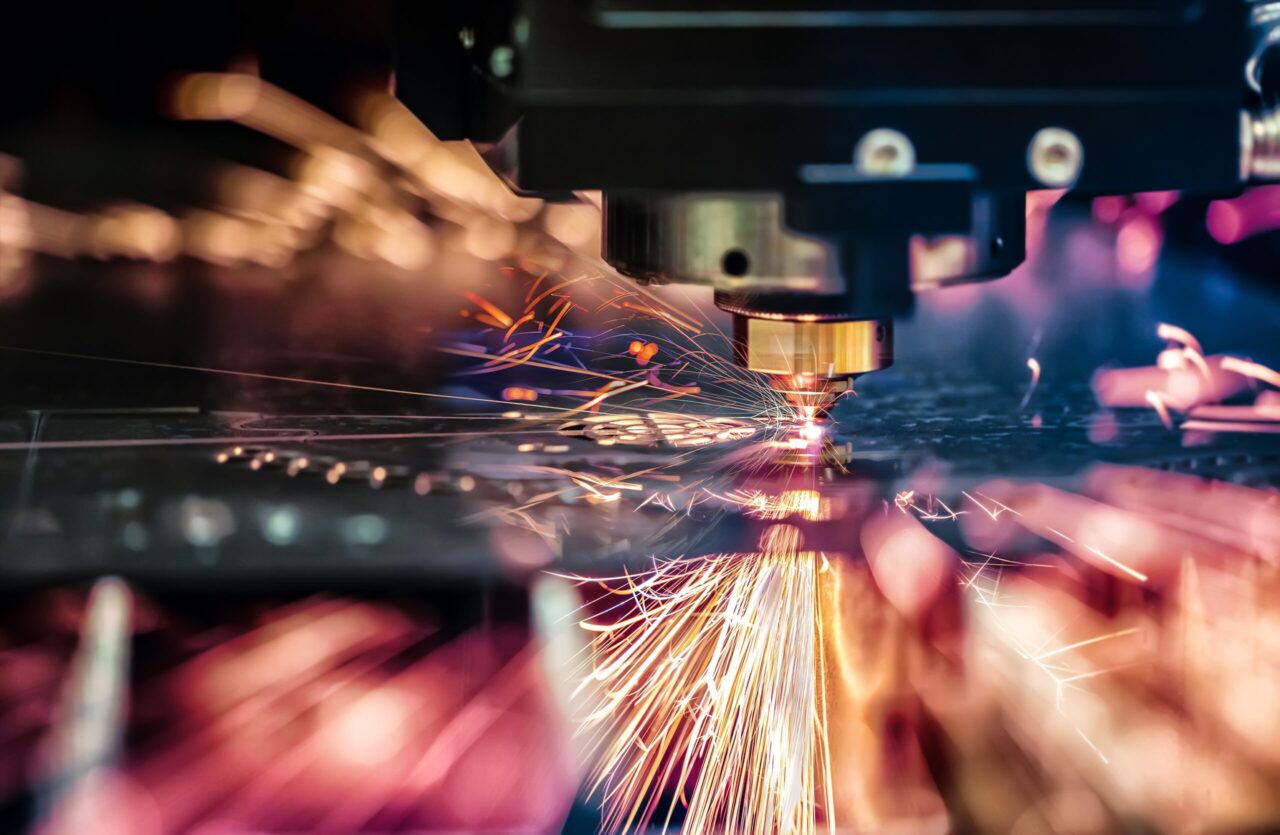

Here at Charles Day Steels, our extensive experience and expertise mean we understand more than most the significant impact laser cutting technology has made on the automotive manufacturing industry. As automotive technology and vehicles become more advanced, the demand for precision, efficiency, and innovative solutions in production processes has never been greater.

Our commitment to utilising state-of-the-art laser cutting technology positions us at the forefront of this evolution, enabling us to meet the complex needs of modern automotive manufacturing.

Applications in Automotive Manufacturing and Auto Parts

Laser cutting technology is extensively used in various applications within the automotive sector, highlighting its versatility and indispensability.

Body Panels

Laser cutting ensures the precise fabrication of exterior body panels, offering perfect fits and reducing the need for extensive finishing work.

Chassis and Frames

The technology aids in the accurate cutting of chassis and frame components, contributing to the structural integrity and safety of vehicles.

Interior Components

From dashboard panels to intricate trim pieces, laser cutting provides the precision necessary for high-quality interior parts.

Exhaust Systems

Laser cutting is crucial in producing complex exhaust system components, ensuring tight tolerances and optimal performance.

Electrical Systems

The production of electrical system components, such as connectors and brackets, benefits from the precision and efficiency of laser cutting.

Prototyping and R&D

Laser cutting supports rapid prototyping and research and development, allowing for quick iterations and innovations in automotive design.

Benefits of Laser Cut Automotive Parts

Precision and Versatility in Automotive Components

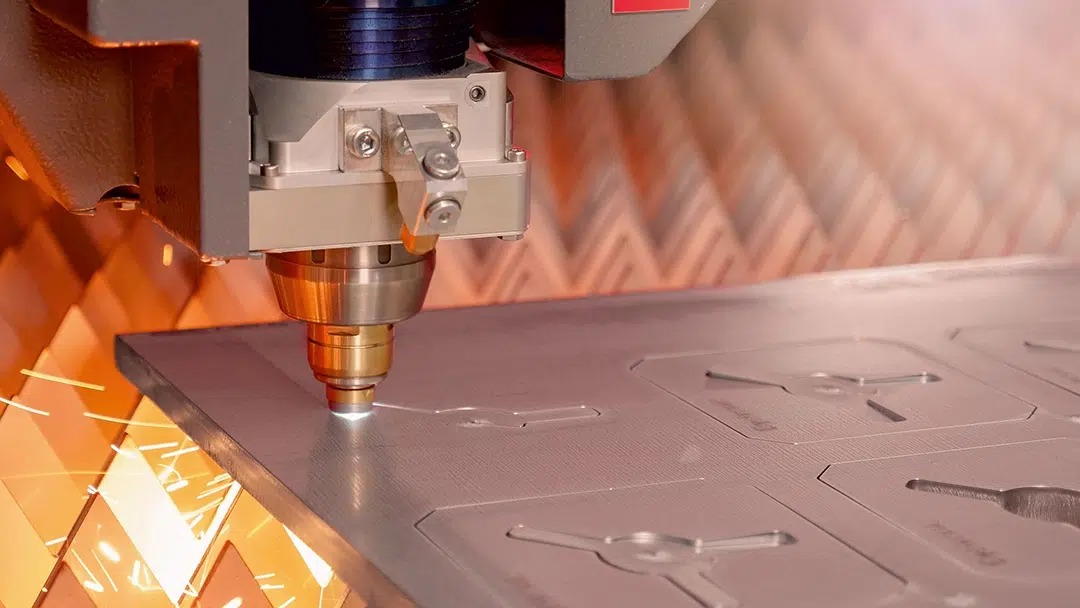

Laser cutting is renowned for its unparalleled precision, which is crucial in the production of automotive components. At Charles Day Steels, we utilise advanced fibre lasers capable of cutting various materials such as steel, aluminium, stainless steel, copper, and brass with exceptional accuracy. This precision ensures that each part meets exact specifications, reducing the need for additional processing and enhancing overall production efficiency.

Key Advantages

- High Accuracy: Our fibre lasers can achieve cutting tolerances as tight as +/- 0.12mm to +/- 0.75mm, ensuring components fit perfectly and function flawlessly.

- Material Diversity: From body panels to intricate engine parts, our laser cutting services handle a wide range of materials, supporting the diverse needs of automotive manufacturers.

Enhancing Fuel Efficiency with Lightweight Materials

The automotive industry’s push towards lightweight materials to improve fuel efficiency and reduce emissions is well-supported by laser cutting technology. Our fibre lasers excel in processing thin sheet metals and reflective materials like aluminium and copper, which are critical for creating lightweight yet durable vehicle components.

Benefits Include

- Minimal Distortion: The low heat generation of fibre lasers minimises material distortion, maintaining the structural integrity of lightweight components.

- Speed and Efficiency: Faster cutting speeds translate to shorter production times, allowing manufacturers to meet stringent deadlines without compromising quality.

Handling Complex Geometries and Customisation

Modern vehicles feature increasingly complex designs, necessitating a high degree of customisation. Charles Day Steels’ suite of seven laser cutting machines, including the UK’s first 20kW fibre laser, offers the flexibility to handle both high-volume production and highly intricate projects.

Capabilities

- Complex Geometries: Our advanced laser cutting technology can create precise cuts in complex shapes, supporting innovative automotive designs.

- Customisation: Whether producing unique prototypes or custom parts, our laser cutting services provide the adaptability required by the automotive industry.

Efficiency and Rapid Turnaround

In the competitive automotive sector, production speed is a significant advantage. Laser cutting technology supports rapid turnaround times, with our 24/7 operation ensuring continuous production and swift delivery.

Operational Efficiency

- 24/7 Production: Continuous operation allows us to meet high demand and tight schedules, ensuring timely delivery of high-quality components.

- Cost-Effective Production: The efficiency of our laser cutting processes reduces operational costs, offering competitive pricing without sacrificing quality.

Improving Downstream Processes

Laser cutting not only enhances the initial manufacturing phase but also streamlines downstream processes. By delivering parts that are accurately cut and ready for assembly, we help automotive manufacturers reduce additional machining and welding steps.

Streamlined Production

- Weld-Prepared Parts: Components are delivered fully weld-prepped for welding, simplifying assembly and reducing production time.

- Reduced Post-Processing: The precision of laser cutting minimises the need for further modifications, enhancing overall efficiency.

Commitment to Quality and Standards

At Charles Day Steels, our operations are guided by industry standards such as BS EN 1090 and ISO 9001, reflecting our dedication to quality and precision. Our continuous investment in cutting-edge technology ensures that we provide the highest quality laser cut car parts for the automotive industry.

Quality Assurance

- Rigorous Inspections: We conduct detailed inspections at every stage of the process to ensure compliance with specifications and standards.

- High Standards: Our commitment to quality ensures that each component meets the highest standards of excellence, contributing to the reliability and performance of automotive products.

Trust Charles Day Steels for Laser Cut Automotive Parts

At Charles Day Steels, we are proud to lead the way with our cutting-edge laser cutting services, helping automakers achieve their goals of high-quality, cost-effective, and efficient production. By continuously investing in the latest technologies, we ensure that our customers reap the benefits of accurate, high-quality profiling, setting a new standard in the automotive manufacturing industry.

For further information and guidance, contact Charles Day Steels for efficient, effective, and professional laser cutting services.