Stainless steel is regarded as a highly durable and low-maintenance material, making it a popular and widely used metal across the globe due to its stand-out properties.

The UK steel industry contributed £2.3 billion to the UK economy in 2023, and is applicable across several industries as an indispensable resource, providing sterile small instruments to large full-scale building construction.

Stainless steels are categorised by their composition type and grade, which results in certain steel types providing the best solution for relevant applications. In this article, we get a detailed overview of stainless steels and their properties.

What is Stainless Steel?

Discovered in Sheffield, the home of Charles Day Steels, by Harry Brearley in 1913, stainless steels are a family of alloys known for their exceptional capability of being heat and corrosion-resistant.

Stainless steel is an alloy of iron and carbon, with a minimum of 10.5% chromium, the major contributor to the metal’s resistance properties. This is established when the chromium reacts with external elements such as water, humidity and air to form a passive layer, which also has a remarkable ability to repair itself when damaged.

Additionally, within the sphere of fabrication and metal profiling, stainless steel is a green material due to its durable lifespan and capability to be infinitely recycled.

The Properties of Stainless Steel

Several key properties of stainless steel make it an excellent material for a variety of processes, these include:

High Tensile Strength

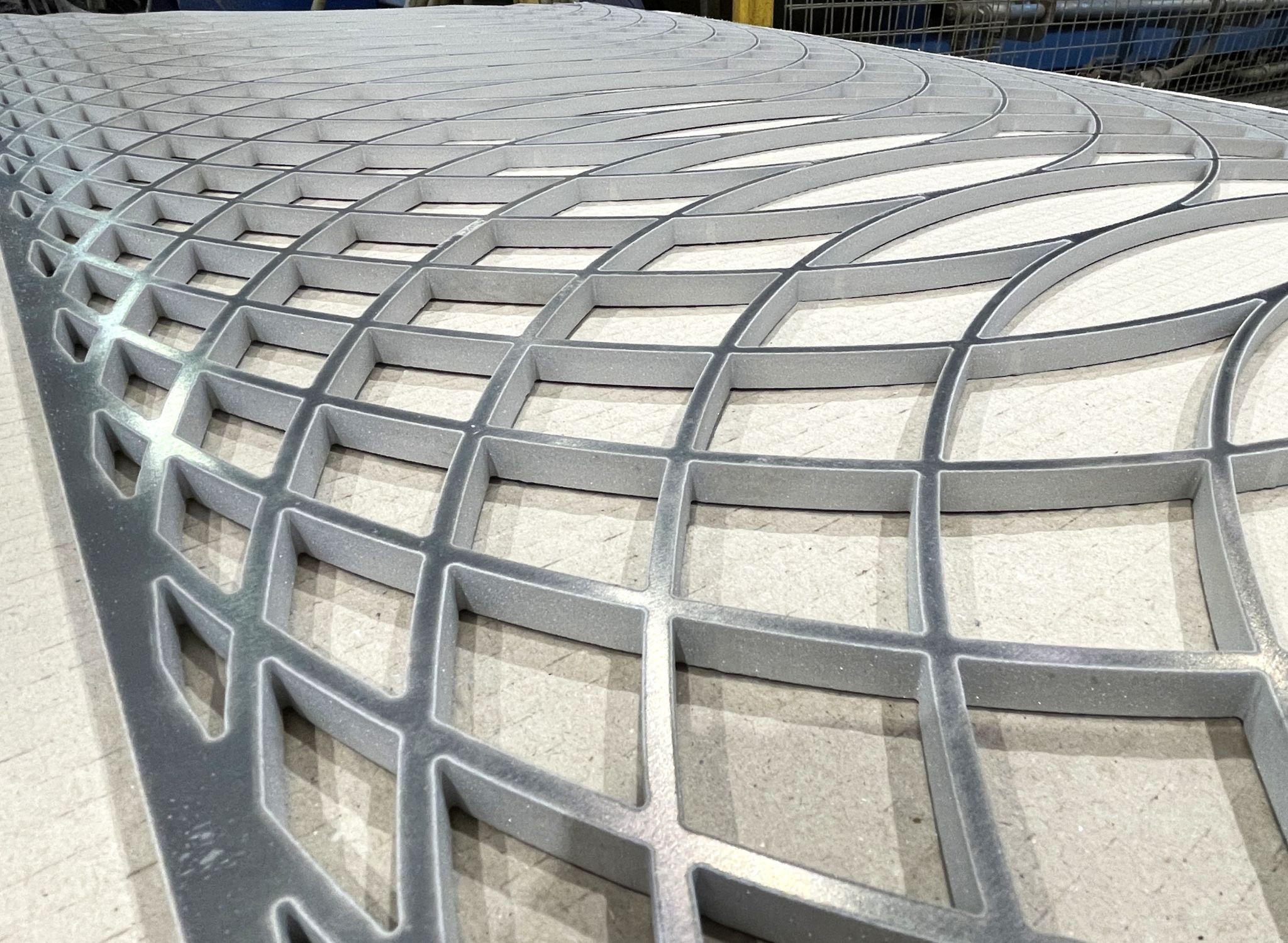

A higher tensile strength dictates the stress level of the material, which offers excellent durability and strength. The great aspect of stainless steel is that despite its strength, it is still malleable enough during bending, pressing and other fabrication processes.

Heat Resistance

Unlike carbon steel, stainless steel offers continuous strength at temperatures as high as 500°C, with some grades exceeding this number without releasing toxic fumes.

Corrosion Resistance

By ensuring the minimum chromium content is 10.5%, stainless steel has superior corrosion resistance abilities due to the self-repairing passive layer that forms on the surface.

Aesthetics

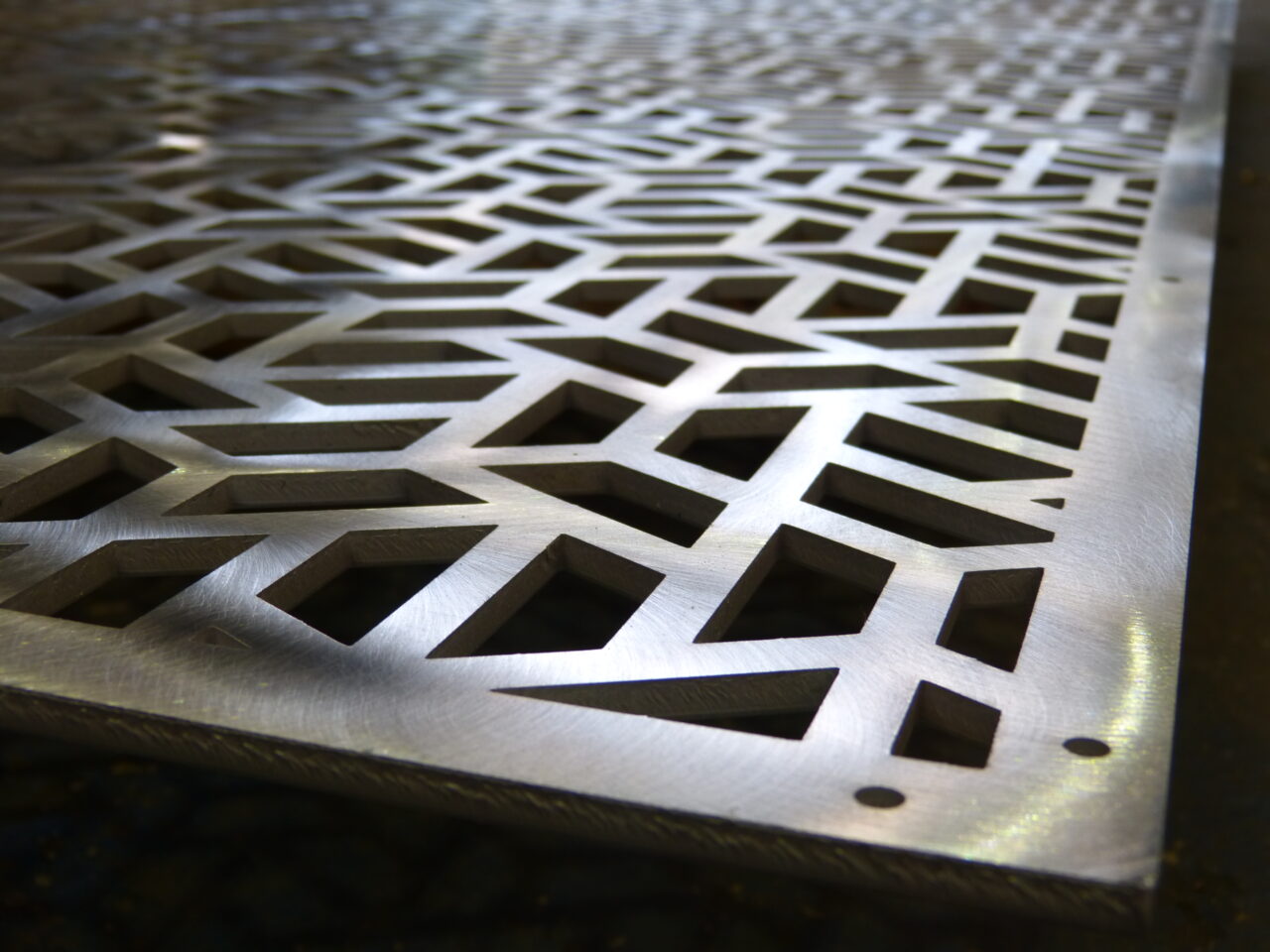

Stainless steel has excellent versatility, offering several options depending on the finish required. The metal can be brushed, tinted, polished, matte, engraved and tailored to meet a spectrum of design requirements.

Hygienic

Due to the durability of stainless steel, it can handle routine sterilisation processes and be easily cleaned. This makes the metal exceptionally useful in the production of cutlery and medical equipment.

Recyclable

Stainless steel can be recycled an infinite amount of times without diminishing in quality and losing its properties. This makes the metal an incredible green resource in construction sectors and production processes.

The Categories of Stainless Steel

There are four major categories of stainless steel that are defined by their structure and intended purpose.

Austenitic

Austenitic stainless steels are the most commonly used, accounting for more than 70% of stainless steel production. Austenitic has a high nickel and chromium percentage, with great formability, corrosion resistance and high-strength properties. This stainless steel is not typically magnetic.

Ferritic

Ferritic stainless steel has a lower chromium percentage compared to austenitic and are typically nickel-free. Ferritic types resist corrosion well and offer ductility and formability. Unlike austenitic, ferritic types have a high amount of ferrite, which gives the stainless steel magnetic properties.

Martensitic

Martensitic offers excellent strength and hardness levels with great heat resistance. Corrosion resistance is moderate but can be improved when heat-treated, yet brittle when welded and typically, the higher carbon content in martensitic steel will result in decreased formability. The majority of martensitic stainless steel has magnetic properties.

Duplex

Duplex stainless steel is a combination of austenite and ferrite, offering a higher strength yield and occasionally greater corrosion resistance. Due to their high strength, duplex types have lower ductility and can be difficult to machine, therefore limiting some of the capabilities. Only certain compositions with higher ferrite content could establish magnetism.

Different Grades of Stainless Steel

Stainless steels are available in different grades, each offering properties that can serve unique purposes. The most common classification systems today utilise both AISI and SAE grading units – with the most common series listed below.

200 Series

- Austenitic family

- Appliances, cutlery, food/drink equipment, and interior components.

300 Series

- Austenitic family

- Highly-ductile

- Food processing equipment, medical devices, construction materials, and household appliances

400 Series

- Ferritic and martensitic family

- Cost-effective

- Automotive exhaust systems, knives, surgical equipment, and agriculture equipment

500 Series

- Martensitic family

- Heat-resistant

- Furnaces, boiler parts, heat shields, and turbine blades

600 Series

- Martensitic family

- Heat-resistance

- Aerospace, heaters, oil and gas equipment, medical devices, and heat treatment

The most common and popular grade of stainless steel is within the 300 series due to its versatility. The first of the two most utilised grades is 304, with a high chromium and nickel content to provide excellent strength and corrosion resistance.

316 is the second grade utilised which offers similar properties, but a higher molybdenum percentage, and provides further protection against chlorides and abrasives found in food manufacturing.

Applications of Stainless Steel

Depending on the material composition and grade type of the stainless steel, there are indispensable applications for the use of this popular metal, including:

- Food Industry

- Construction

- Aerospace

- Medical Industry

- Transportation

- Power Generation

Discover Exceptional Metal Profiling with Charles Day Steels

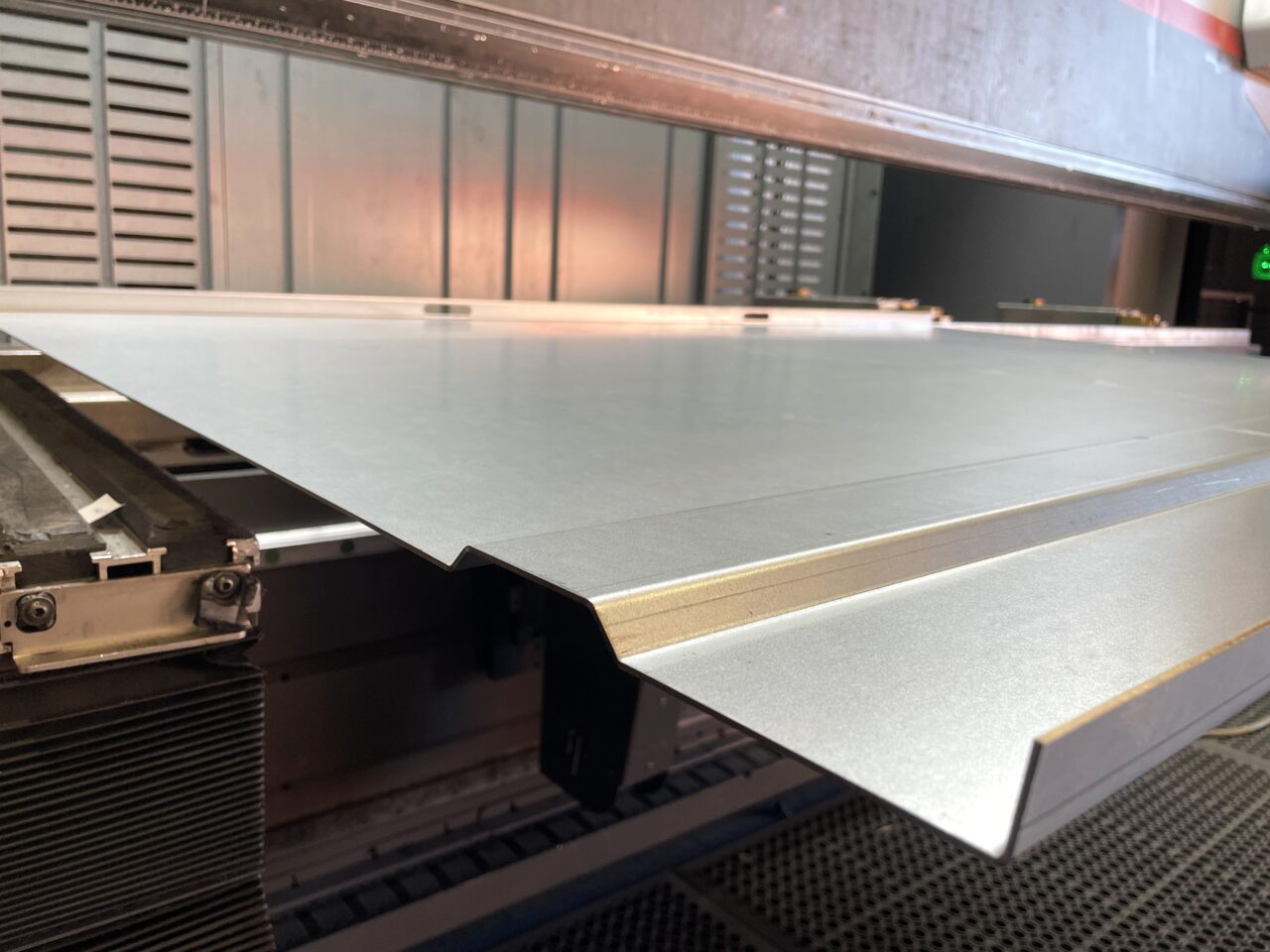

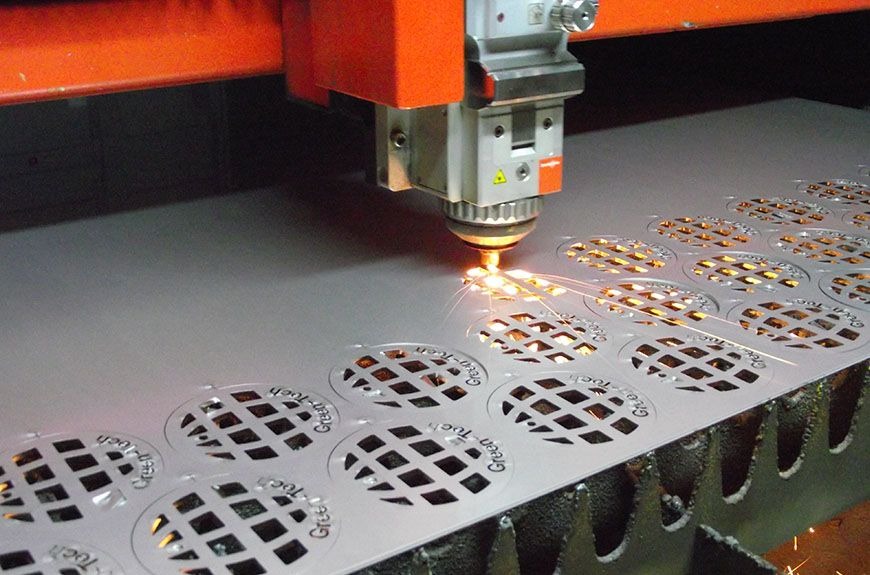

Based in the birthplace of stainless steel, Charles Day Steels offers quality flame, plasma, waterjet and laser cutting in the heart of Sheffield, the steel city. We can cut stainless steel, regardless of complexity and scale, with the ability to source materials within 24-48 if we do not carry what you require from our large inventory.

Selecting experts in metal profiling guarantees an in-depth understanding of various metal properties, tolerances, and what is suitable depending on project objectives. With over 40 years in the industry, we are confident in our portfolio of cutting and profiling services, which is why we continuously invest in the latest technology for our clients.

If you’re looking for superior metal profiling and quality service, get in touch with a member of our expert team today to discuss your project requirements for a no-obligation quote.