At Charles Day Steels, we understand more than most the critical importance of precision in metal fabrication and profiling processes. This extends across various industries, including construction, aerospace engineering, and the production of industrial machinery, where the accuracy of metal components is crucial.

Our approach to ensuring this precision lies in our comprehensive quality assurance program, which serves as the backbone of our metal profiling services. Quality assurance at Charles Day Steels is not just a procedural step; it is the foundation upon which our operations are built. From the initial customer inquiry to the final delivery of precision-engineered metal components, our process is underscored by rigorous quality control measures aimed at guaranteeing the highest standards of excellence.

The Significance of Quality Assurance in Metal Profiling

As professionals in metal profiling with over four decades of experience, we believe that accuracy and precision are non-negotiable elements in metal fabrication. The reliability and performance of structures, devices, and machinery depend significantly on the quality of their metal components.

Quality assurance acts as a protective measure, ensuring that every fabrication process from laser cutting to welding adheres to stringent precision standards, thereby maintaining the structural integrity and functionality of the components produced.

Why Quality Assurance in Metal Profiling is Important

Quality assurance in metal profiling is vital for ensuring the integrity, reliability, and safety of metal components used across various industries. Some reasons why include:

Precision and Accuracy

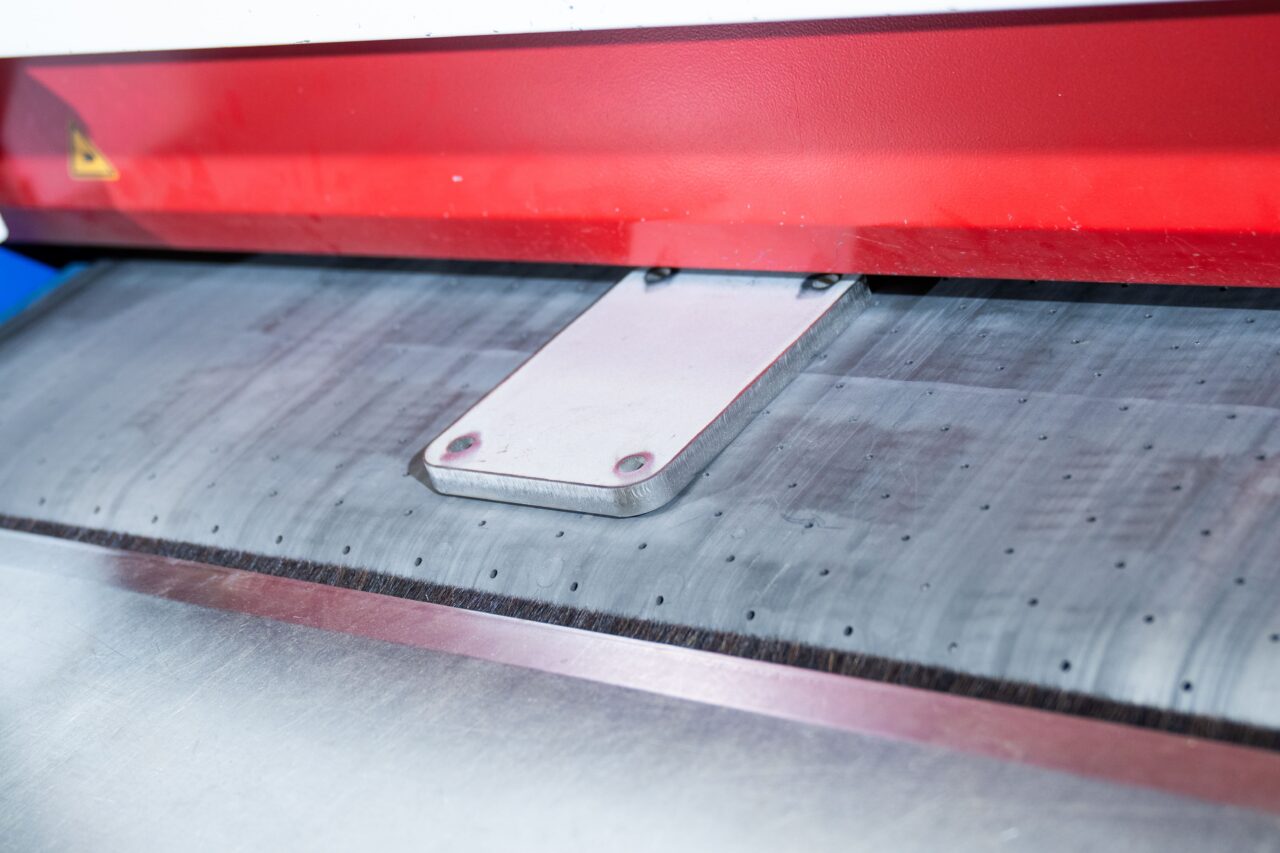

Metal profiling involves cutting, shaping, and forming metal according to precise specifications. Even a minor deviation from these specifications can lead to defects or failures in the final product. Quality assurance processes ensure that the profiling machinery is calibrated correctly and that each cut or shape meets the required dimensions with high accuracy.

Material Consistency

Different grades of metal have varying properties such as strength, hardness, and corrosion resistance. Quality assurance verifies the consistency of the metal material being used for profiling to ensure that all components fabricated from it will perform consistently and reliably under operational conditions.

Mechanical Properties

The mechanical properties of metal, including tensile strength, ductility, and toughness, are critical factors in determining the performance and durability of metal components. Quality assurance involves testing these properties to ensure that the profiled metal meets the specified requirements and can withstand the intended mechanical stresses without failure.

Surface Finish and Quality

The surface finish of metal components not only affects their aesthetic appeal but also their functionality and performance. Quality assurance processes monitor and control factors such as surface roughness, burrs, and defects to ensure that the finished profiles meet the required standards for appearance and functionality.

Compatibility and Interchangeability

In many applications, metal components need to fit together precisely or interface with other parts. Quality assurance ensures that profiled metal components are manufactured to standardised dimensions and tolerances, allowing for seamless assembly and interchangeability of parts without the need for additional machining or modifications.

Safety and Reliability

In industries such as aerospace, automotive, and construction, the failure of metal components can have serious consequences, including accidents, injuries, and financial losses. Quality assurance in metal profiling is essential for minimising the risk of component failure and ensuring the safety and reliability of the end products.

Regulatory Compliance

Many industries are subject to strict regulations and standards governing the quality and performance of metal components. Quality assurance processes ensure that profiled metal products meet these regulatory requirements, enabling manufacturers to demonstrate compliance and avoid potential legal or financial penalties.

Customer Satisfaction

Ultimately, quality assurance in metal profiling is about meeting or exceeding customer expectations. Consistently delivering high-quality, defect-free metal components builds trust and confidence among customers, leading to long-term relationships and repeat business.

Commitment to Standards and Precision

Here at Charles Day Steels, our operations are guided by our commitment to industry standards such as BS EN 1090 (of which we are EXC 4 accredited) and ISO 9001, reflecting our dedication to maintaining exemplary quality levels in all our endeavours. To achieve unparalleled precision in metal profiling, we leverage cutting-edge technology and machinery, enabling us to meet the demanding accuracy requirements of our projects. Some of the many ways Charles Day Steels ensures unrivalled quality and precision include:

Comprehensive Quality Checks

Quality assurance at Charles Day Steels is an ongoing commitment. Our team conducts detailed inspections at every stage of the metal profiling process to ensure compliance with specifications and standards. This meticulous attention to detail ensures that we deliver products that meet our high standards.

Adaptability to Client Requirements

Understanding that project requirements vary, we offer a broad range of materials and specifications to cater to diverse needs. Our capability to manage both small and large-scale projects showcases our versatility and commitment to client satisfaction.

Efficiency and Timely Delivery

In recognition of the importance of timeliness in today’s business landscape, we have implemented an efficient production model that ensures prompt delivery of our services without compromising quality. Our commitment to efficiency is a testament to our dedication to meeting our clients’ needs reliably and punctually.

Quality Assurance in Metal Profiling: The Charles Day Steels Difference

What distinguishes Charles Day Steels is our profound commitment to quality, precision, and client satisfaction. We recognise the significance of meticulous attention to detail and are dedicated to ensuring that each component we produce aligns with the highest standards of excellence. Our state-of-the-art facilities and skilled team members are united in this commitment, making us the trusted partner for precision metal profiling needs.

With over four decades of industry experience, our reputation for excellence is well-established. Regardless of the service – be it laser cutting, waterjet cutting, flame cutting, or plasma cutting – clients can rely on us for outcomes that surpass their expectations.