Here at Charles Day Steels, our 40-plus years of industry experience and expertise inform all of our practices. As an industry leader, we recognise that steel cutting tolerances are a vital aspect of metal fabrication, and are the cornerstone of precision engineering.

The quality, functionality, and aesthetic appeal of the final product heavily rely on these tolerances, which is why it is essential to have a thorough and informed understanding prior to steel cutting and fabrication. With our series of cutting services, including laser, waterjet, flame, and plasma, we at Charles Day Steels aim to deliver leading services to accommodate even the most stringent, complex, and precise of projects.

Understanding Steel Cutting Tolerances

Steel cutting tolerances are the permissible variations in the dimensions and shapes of steel after it has been cut. These tolerances are typically specified as a range, for example, ±0.25mm, and represent the acceptable deviation from the intended size. This precision is critical for ensuring that parts fit seamlessly within final assemblies, which is essential for both the functional integrity and visual quality of the end product.

Factors influencing tolerances include:

- Type of Steel: Different steel grades have unique properties that affect how they respond to cutting.

- Cutting Method: Each cutting technique has its own set of precision capabilities.

- Material Thickness: Thicker materials may require larger tolerances due to increased difficulty in cutting.

- Machine Accuracy: The precision of the cutting equipment directly impacts tolerance levels.

- Industry Standards: Adhering to standards such as BS EN 10051:2010 ensures consistent quality across products.

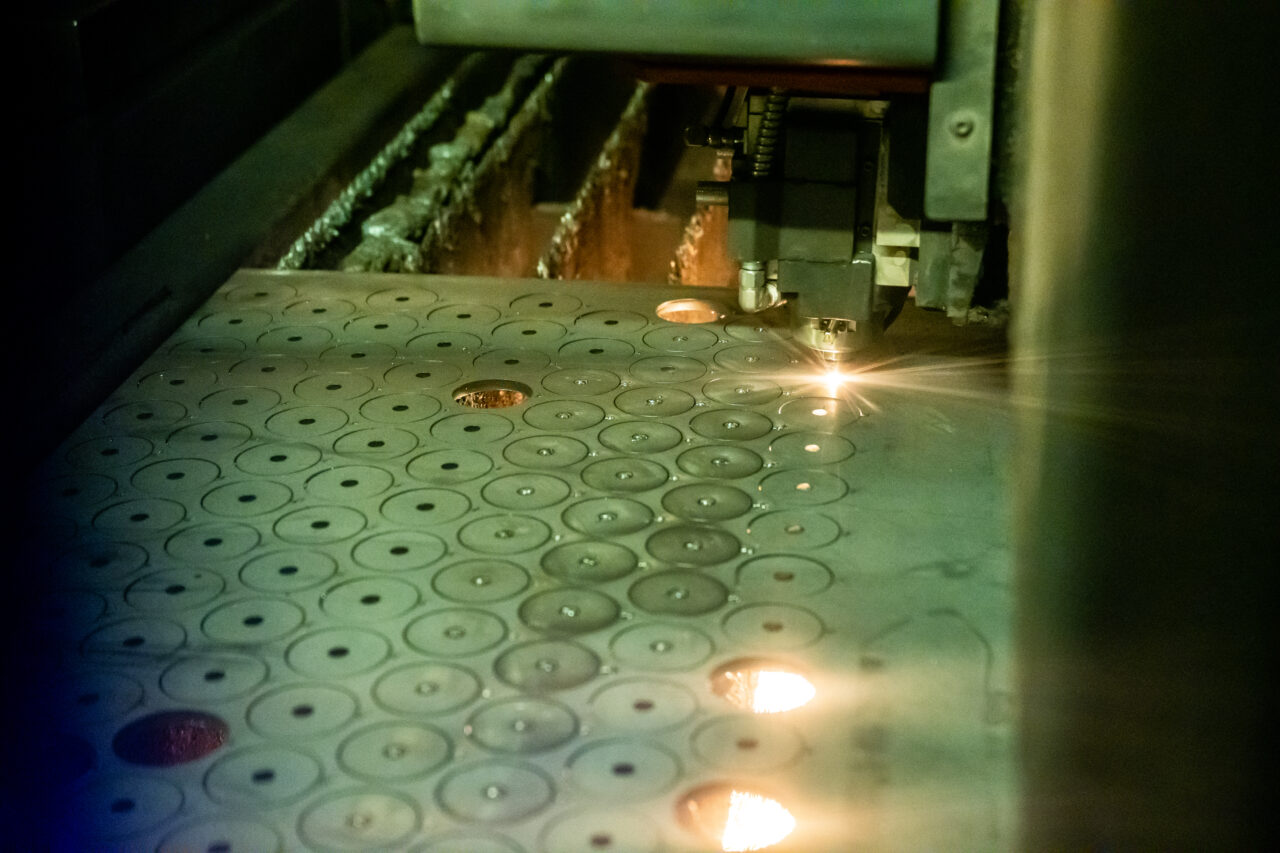

Laser Cutting: Precision in Steel Cutting Tolerances

Laser cutting stands out for its ability to handle intricate designs with exceptional precision. At Charles Day Steels, laser cutting is versatile, accommodating diverse materials and sizes up to 6 meters x 2.5 meters. The hallmark of this technique is its strict tolerance level, maintained at +/- 0.12mm. This precision makes laser cutting ideal for applications where accuracy is paramount, such as in the aerospace and medical industries.

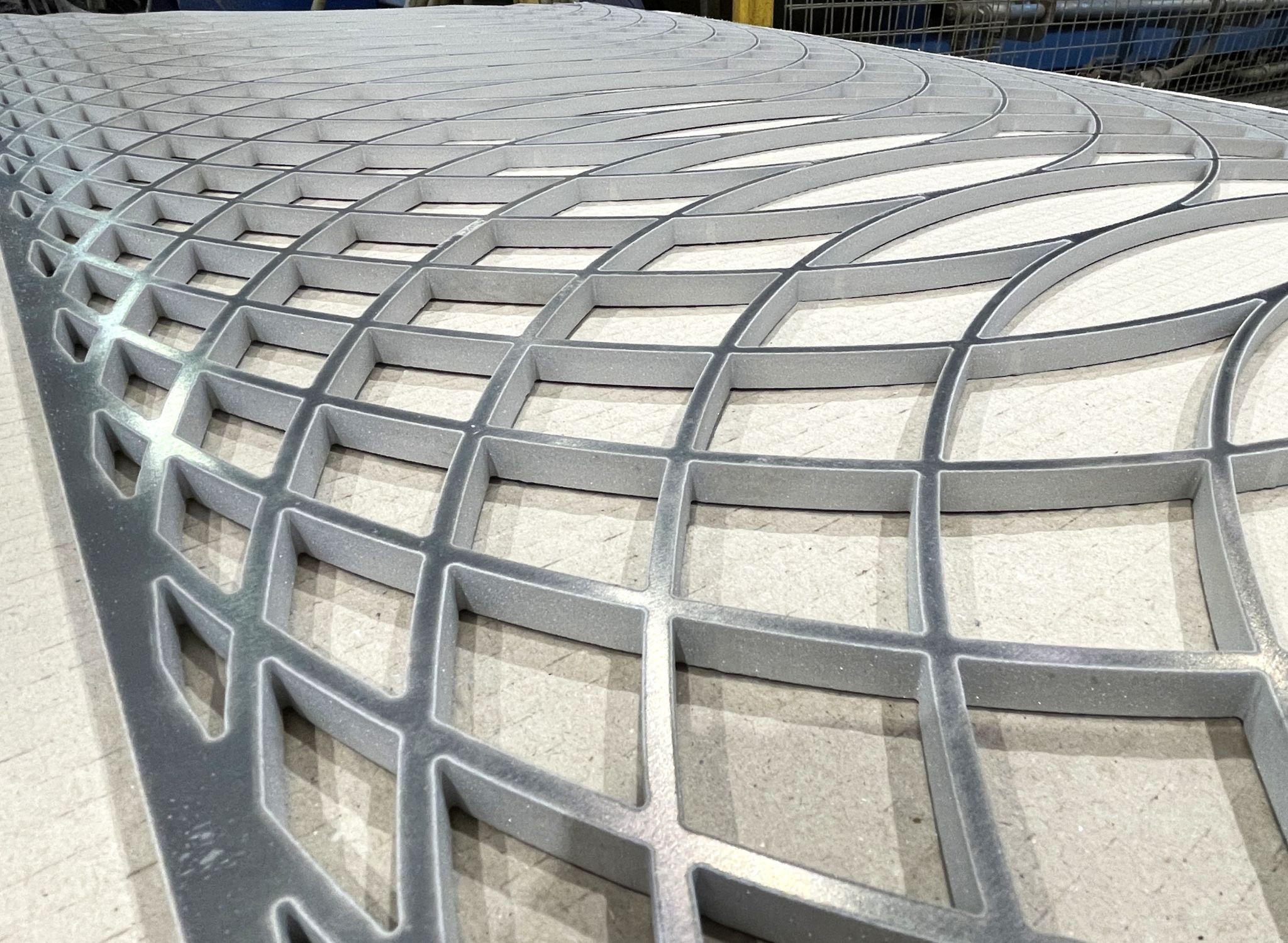

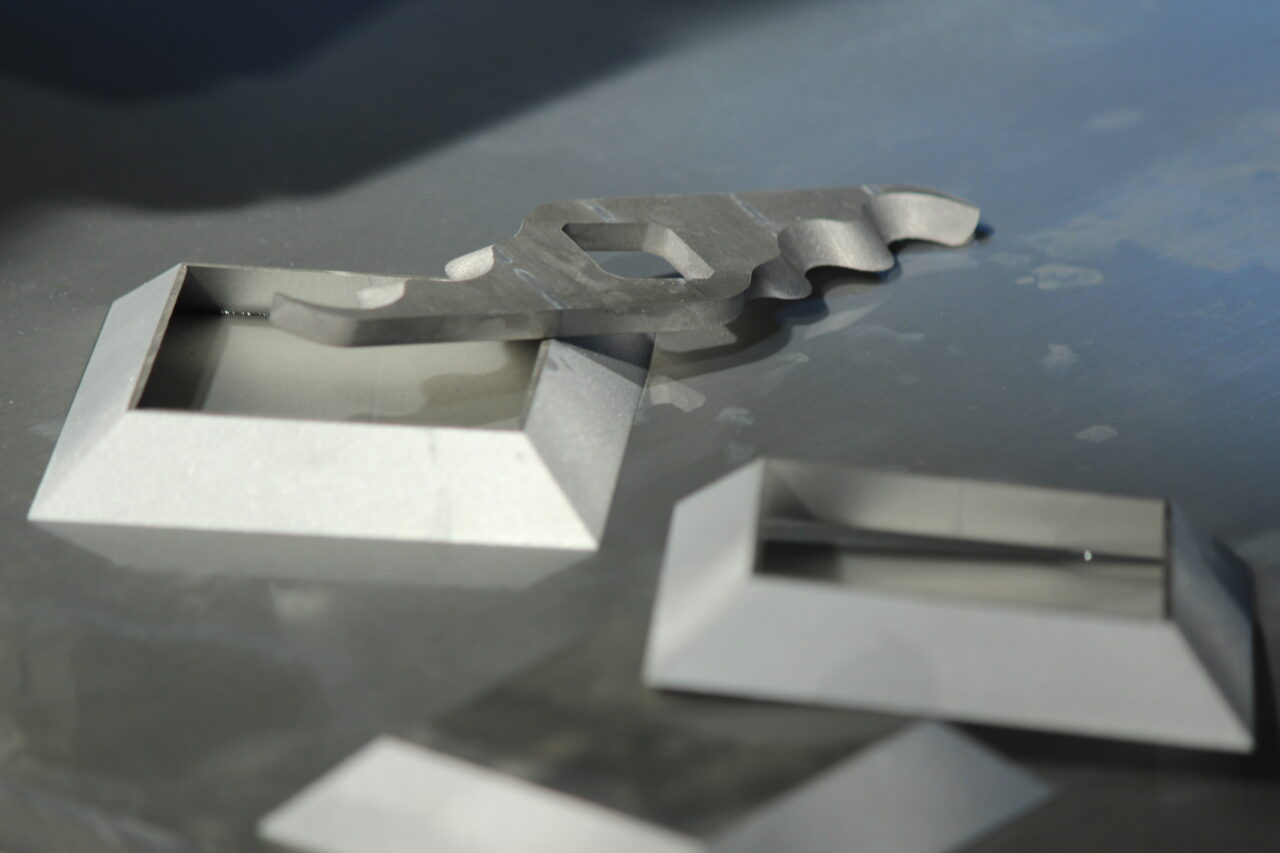

Waterjet Cutting: Versatility in Steel Cutting

Waterjet cutting is renowned for its versatility and is particularly effective for materials sensitive to high temperatures. Charles Day Steels’ waterjet cutting capabilities extend to large sizes up to 9 meters x 4 meters. The tolerances in waterjet cutting vary from +-0.25mm to >41mm, depending on the material thickness. This method is especially beneficial for materials that cannot withstand the heat of traditional cutting methods.

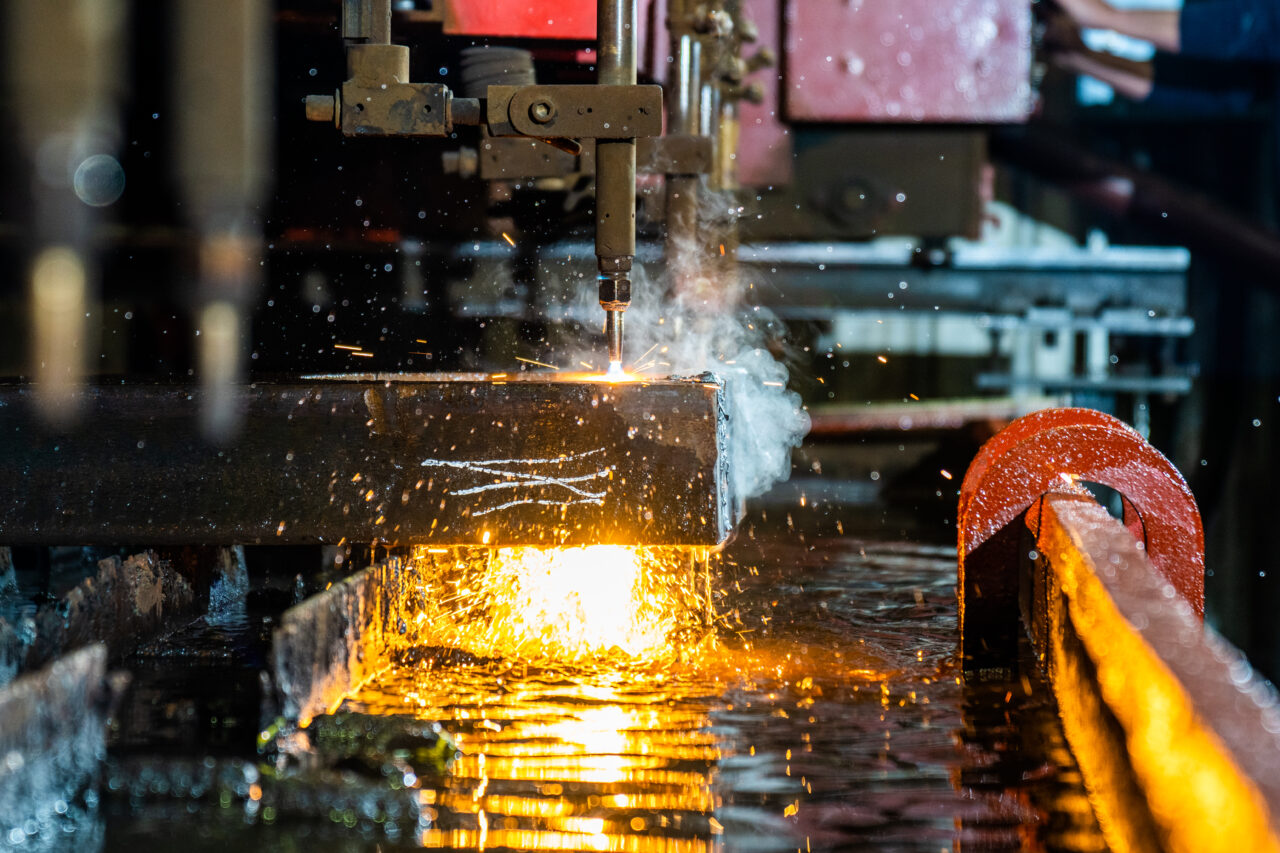

Flame Cutting: Economical Steel Cutting with Varied Tolerances

Flame cutting is a cost-effective solution, particularly suited for thick carbon and low alloy steels. At Charles Day Steels, flame cutting services accommodate materials up to 42 meters x 5 meters. The tolerances range from +/-2.0mm to +/-6.0mm, influenced by the material’s thickness and length. This method is typically preferred for large-scale projects involving thick steel, such as heavy machinery manufacturing.

Plasma Cutting: Versatile and Precise Steel Cutting

Plasma cutting strikes a balance between speed and precision, often chosen for materials like stainless steel, it can handle sizes up to 12 meters by 5 meters, with a typical tolerance of +/- 1.0mm. Plasma cutting is valued for its ability to efficiently cut through various material thicknesses while maintaining a high level of accuracy.

Charles Day Steels and The Art of Precision in Steel Cutting

Understanding and applying the right tolerances in steel cutting is crucial for achieving excellence in metal fabrication. Charles Day Steels exemplifies how varying cutting methods are tailored to meet different tolerance requirements, material types, and project scales. Whether it’s the precision of laser cutting, the adaptability of waterjet cutting, the economic efficiency of flame cutting, or the balanced performance of plasma cutting, recognising and utilising these tolerances is fundamental for ensuring high-quality results in any steel cutting project.

For further information and guidance regarding our steel cutting tolerances, please contact our team at Charles Day Steels today.