At Charles Day Steels, we understand that quality and compliance are non-negotiable when it comes to industrial manufacturing. Our commitment to delivering exceptional metal profiling services means we adhere to the highest standards, one of which is the BS EN 1090. But what exactly is BS EN 1090, and why is it crucial for businesses working with structural steel and aluminum components?

What is BS EN 1090?

BS EN 1090 is a European standard that governs the fabrication and assembly of steel and aluminum structures. Officially titled “Execution of steel structures and aluminum structures,” this standard is a vital part of the Construction Products Regulation (CPR) within the European Union and the UK. It ensures that structural components meet stringent safety, performance and quality requirements before they enter the market.

The standard is divided into several parts, with BS EN 1090-1:2009 + A1:2011 being particularly significant as it outlines the requirements for conformity assessment of structural components. This part of the standard mandates CE marking and UKCA marking, certifying that products meet the necessary safety standards for use in construction.

Why BS EN 1090 Matters

Compliance with BS EN 1090 is not just a legal obligation; it’s a guarantee of quality and safety. Here’s why it’s essential:

Regulatory Compliance

Adhering to BS EN 1090 is a legal requirement for manufacturers and suppliers of structural steel and aluminum components. Non-compliance can result in significant legal and financial repercussions, including fines and project delays.

Market Access

The CE and UKCA markings, which come from compliance with BS EN 1090, are mandatory for selling structural components within the EU and UK markets. Without these certifications, businesses may find themselves unable to compete in these regions.

Quality Assurance

BS EN 1090 ensures that every structural component is manufactured to the highest standards, minimising the risk of failure in use. This is particularly important in industries such as construction and nuclear, where safety is paramount.

Customer Confidence

For our clients, knowing that we comply with BS EN 1090 provides peace of mind. It assures them that they’re receiving products that meet the highest quality and safety standards, which is essential for the integrity of their projects.

BS EN 1090 at Charles Day Steels

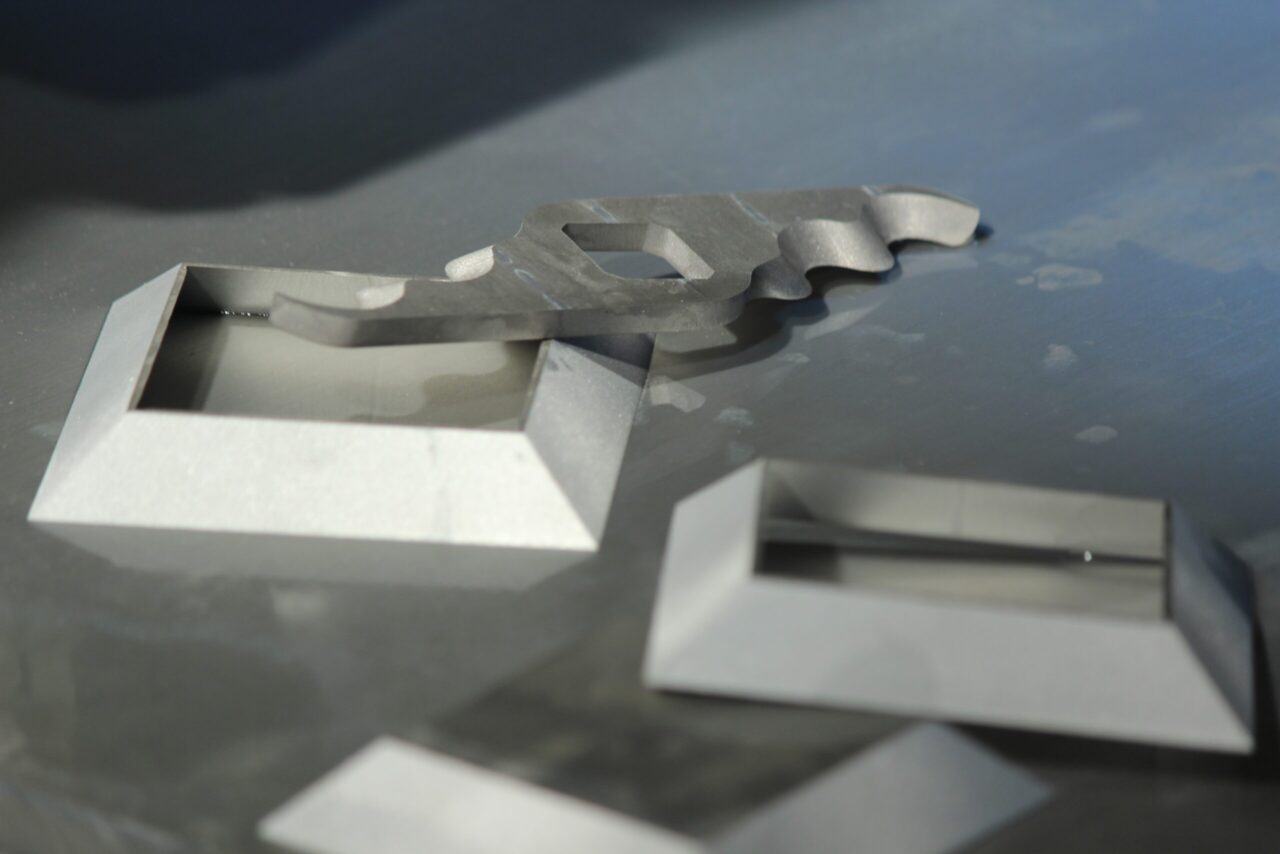

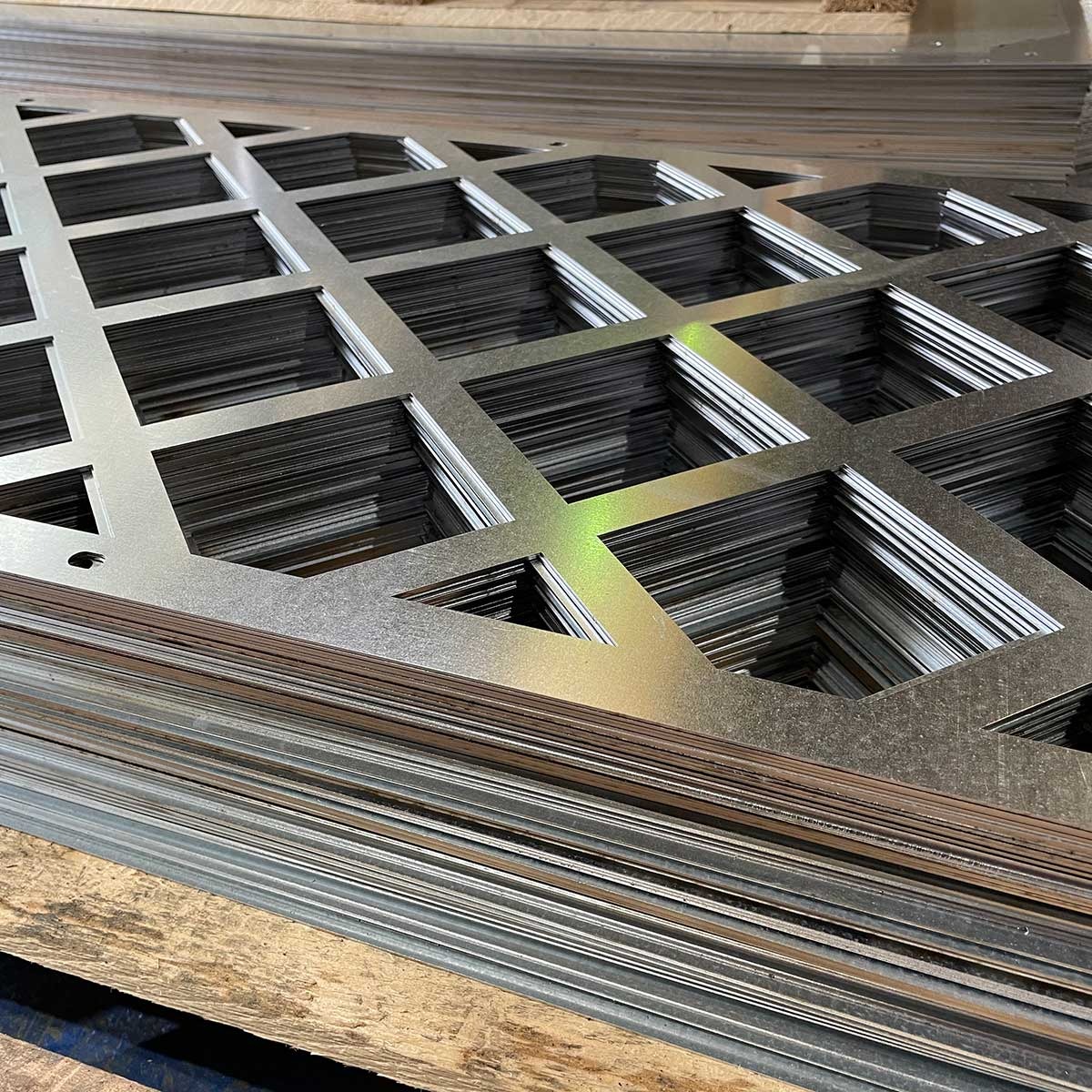

At Charles Day Steels, we take BS EN 1090 compliance seriously. Our factory production controls align with the strict requirements of BS EN 1090-1 EXC4, the highest execution class, which applies to the most demanding projects, including those in the nuclear sector. This means that from the initial drawing to the final delivery, every step in our process is meticulously controlled and documented to ensure compliance.

Our adherence to BS EN 1090 extends across all our profiling services, including laser cutting, waterjet cutting, flame cutting, and more. By maintaining this standard, we ensure that the components we produce are not only compliant but also of the highest quality, delivering superior performance and reliability.

Trust Charles Day Steels for BS EN 1090 Compliant Solutions

At Charles Day Steels, our commitment to BS EN 1090 compliant solutions underpins everything we do, ensuring that our clients receive products that are compliant, reliable and of the highest quality. Whether you’re in construction, aerospace, or any other industry requiring precision and durability, you can trust that our services meet these rigorous standards.

For more information on our BS EN 1090 compliance or to discuss your project requirements, contact the team at Charles Day Steels today. We’re here to ensure that your project meets the highest standards from start to finish.