At Charles Day Steels, we understand the difference between laser etching and laser engraving can be confusing. With over 45 years of expertise, we know how important it is to choose the right profiling service for your industry.

Laser cutting within modern manufacturing has been indispensable in product customisation and design. The rise of laser etching and engraving boasts versatility that delivers excellent results on a range of materials. Both processes are especially beneficial for part traceability within the manufacturing pipeline. Although laser etching and engraving appear similar, they each have their own nuanced advantages. But which method is best for your project requirements?

Understanding Laser Etching

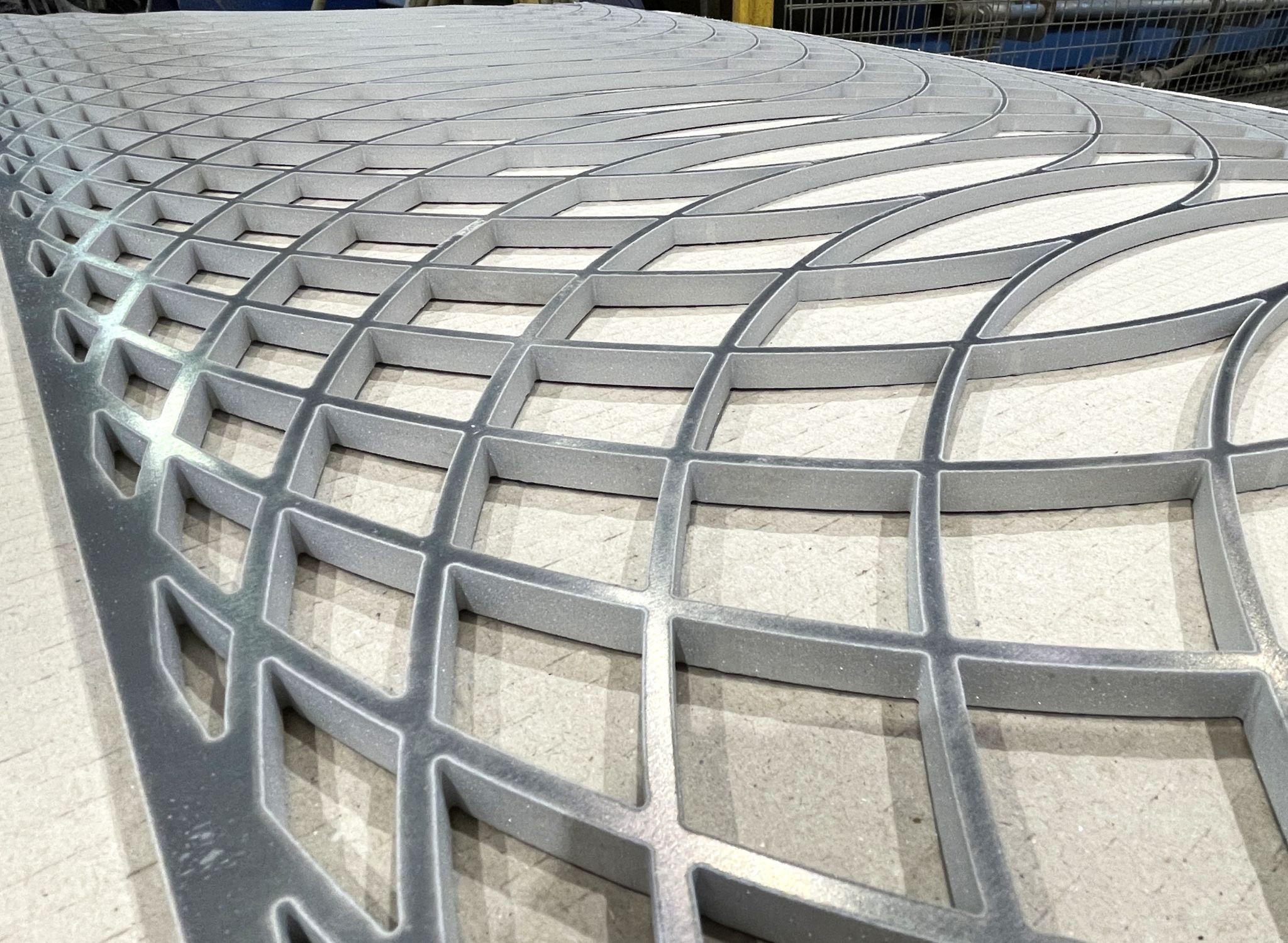

Laser etching provides high-quality results with minimal impact. A concentrated heated beam alters the surface rather than vaporising material below the external layer. The laser etches visible contrast and/or alters colour to leave a permanent flush result on the material exterior. Charles Day Steels invests in state-of-the-art machines at our 24/7 profiling cutting facility to deliver high-quality results with rapid lead times.

Key Features of Laser Etching

Material Versatility

Laser etching can be used across various materials, including metal, anodised aluminium, wood, ceramics, glass, paper, acrylics and some plastics.

Material Thickness

Laser etching has a non-invasive shallow depth, allowing versatility that can be used on both thick and thin materials. This makes laser etching excellent for a spectrum of processes, particularly for delicate projects.

Tolerance and Precision

A focused laser beam facilitates the creation of intricate designs, offering seamless integration with CAD software. Our machines allow for iterations and batch processing without compromising quality.

Speed and Efficiency

Laser etching is typically faster and ideal for mass production. It also uses less heat and energy, causing a reduction in operation costs. Rapid results allow for responsive turnaround times, providing impressive lead times whilst adhering to high specifications.

Exploring Laser Engraving

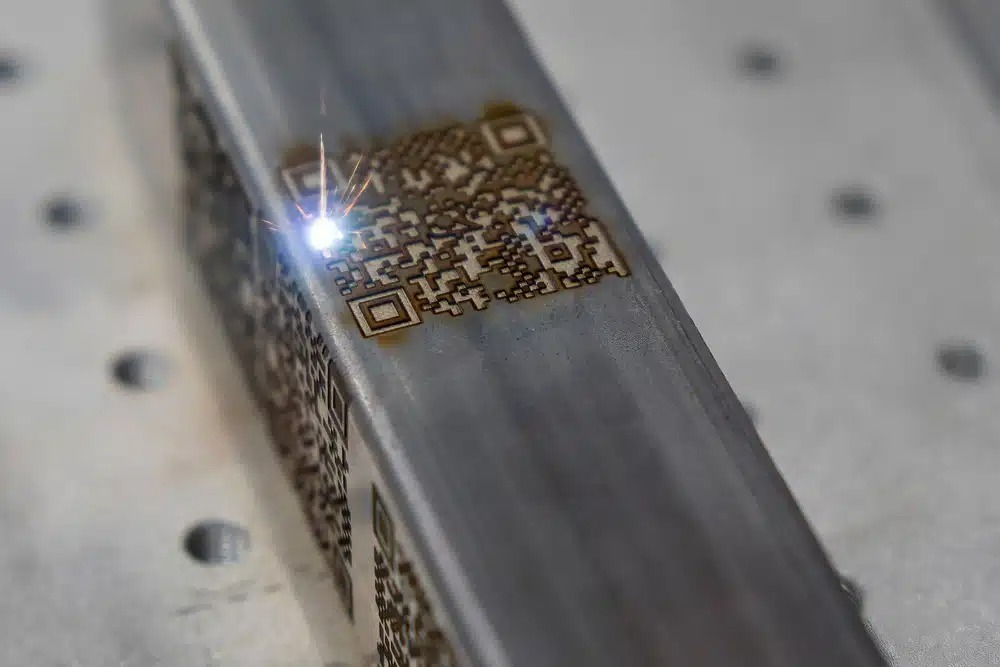

On the other hand, laser engraving uses high-intensity localised lasers that remove material from the product surface. This is especially useful in providing tactile finishes to create a cavity or indentation. This is applied across industries to provide batch numbers, serial codes, QR codes, and downstream maintenance data for reliable traceability. Charles Day Steels utilises 7 state-of-the-art machines, maintaining superior capabilities and minimal heat distortion for project needs.

Key Features of Laser Engraving

Precision and Quality

Laser engraving provides elaborate detailing, perfect for intricate logos, text, or graphics. Integrated with CAD software, digital designs can efficiently transition to deliver tangible results.

Maximum Durability

Laser engraving is adaptable, useful on a magnitude of projects and robust metals. Since engravings are below the surface level, they have the ability to handle more abrasive treatments and impact damage.

Speed and Efficiency

Laser engraving provides rapid results through the use of automation, reducing turnaround times. Due to the lack of contact between the laser and the material, it enables a sustainable and efficient method of laser engraving.

Tactile Design

The use of laser engraving creates grooves that allow for tactile and intricate designs. This is especially useful for data matrix codes, which allow for essential supply chain traceability along the production line.

Laser Etching and Engraving Applications

- Electronics

- Signage

- Promotional Products

Choosing the Right Method for Your Project

Material Type and Thickness

When requiring profile methods on more delicate and thin products, laser etching is often the best choice since it does not vaporise material on the surface layer. Whilst laser etching can be used on thick materials, laser engraving allows for intricate and detailed designs on thick, robust metals.

Customisation and Tailoring

Both laser etching and engraving can deliver powerful and tailored designs for your project. Laser engraving allows for versatile implementations, bespoke logo productions and detailed text, such as VINs for the automotive industry. Laser engraving is an excellent choice for aesthetic purposes and complex decorative features.

Cost Considerations

The cost can vary significantly based on the project, material, and cutting requirements. Laser etching is faster and requires less energy, therefore it tends to be a more cost-effective option for mass production. However, laser engraving showcases remarkable intricacies with maximum quality for tailored needs.

Contact Charles Day Steels for Professional Laser Etching and Engraving

Deciding between laser etching and laser engraving depends on your project requirements. Both laser etching and engraving profiling methods offer incredible results in modern manufacturing. Ensuring detailed results for effective part traceability, bespoke designs and aesthetic results.

Charles Day Steels understands every project is different, which is why our dedicated team is here to help you find the right method when choosing between laser etching and engraving. Our state-of-the-art machines deliver high specifications, offering precision cutting up to 50mm and maintaining the highest level of productivity for your project.

Get in touch with our team to discuss your laser etching and engraving requirements and find the perfect solution for your project.