Laser Etching and Engraving in Sheffield

Here at Charles Day Steels, we recognise the impact that laser cutting has made upon modern manufacturing, and how materials can be processed and customised. With a host of laser etching and engraving services on offer at our state-of-the-art profile cutting facility, we can provide laser etching and laser engraving for a range of applications including industrial, automotive, and electronics sectors.

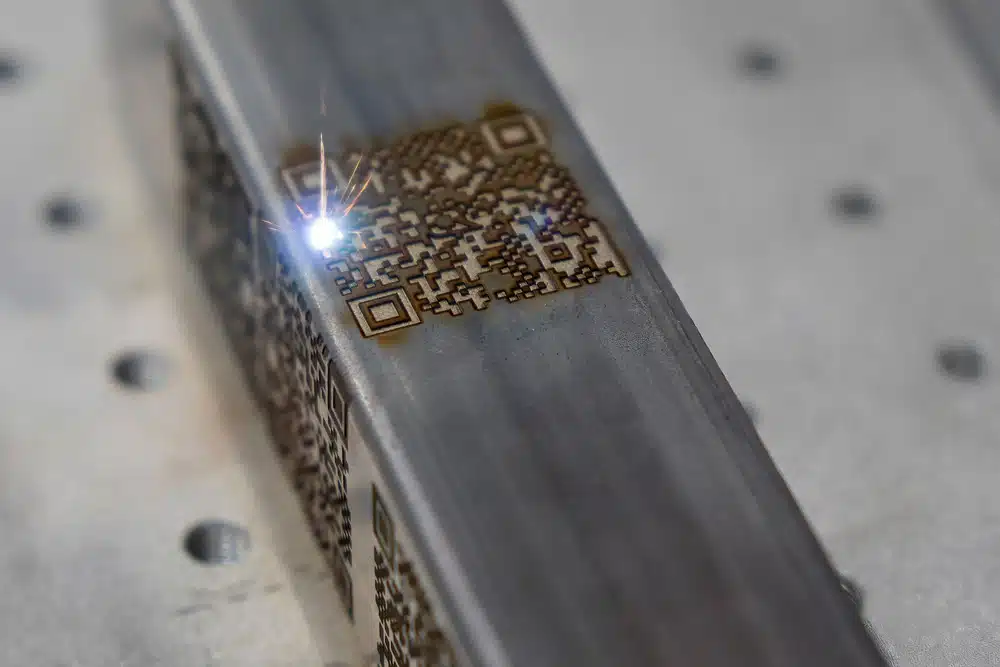

Typically used across industries to apply batch numbers, serial codes, QR codes, and downstream maintenance data, laser etching and engraving is an essential process for reliable supply chain traceability. Laser marking is an extremely versatile profiling method, and is often utilised for aesthetic purposes including logos and complex decorative features. These aesthetic applications can be used on a series of materials such as stainless steel, aluminium, acrylic, wood, and more; no matter your laser engraving requirements, we here at Charles Day Steels have the expertise and on-site capabilities to create laser etchings and engravings that exceed your expectations.

What Are The Differences Between Laser Etching and Laser Engraving?

Despite both methods being laser-based processes used for marking and aesthetic designs, laser etching and laser engraving differ in the ways they interact with materials and the type of marks produced.

Laser Etching

Unlike laser engraving, laser etching does not remove material from the surface, but instead alters its appearance by causing a visible contrast and/or colour change. Particularly useful on materials such as metal, anodised aluminium, and some plastics, laser etching is capable of modifying a material’s surface without significant penetration; resulting in a flat etching that may not be tactile due to minimal material being removed.

Laser Engraving

On the other hand, laser engraving removes material from the surface of the material with a high-intensity laser beam to produce a tactile cavity or indentation. Commonly used for engraving logos, text, and intricate designs, laser engraving is extremely versatile. Creating a groove that can be felt when touched, the overall contrast and depth of the engraving are dependent on the speed and power of the laser, and its settings allow for precise control over the final product.

What Are The Benefits of Laser Etching and Engraving?

Precision and Elaboration

Laser etching and engraving have gained acclaim for their unmatched precision and elaborate detailing. Leveraging a focused laser beam facilitates the creation of meticulously accurate designs, intricate logos, precise text, or graphics on a diverse array of materials. With the right configuration and parameters, a laser can precisely engrave to the specific depth mandated by the automotive industry for marking VINs. This exceptional precision ensures the replication of intricate designs with seamless consistency, elevating the aesthetic appeal and intrinsic value of your products.

Adaptability and Diversity of Materials

A paramount advantage of laser etching and engraving lies in their adaptability to diverse materials. Whether laser marking is required on robust metals, engraving on delicate substances, or etching on textured surfaces, our advanced laser technology adeptly accommodates all requirements. This adaptability positions it as the optimal choice across a spectrum of industries, including automotive, electronics, signage, and promotional products.

Customisation and Tailoring

In the current competitive market landscape, customisation stands as a pivotal aspect of product offerings. Laser etching and engraving emerge as powerful tools for tailoring items to meet individual preferences and demands. From corporate mementoes to embedding unique serial numbers on industrial components, laser technology facilitates seamless customisation, fostering heightened customer loyalty and bolstering brand recognition.

Operational Efficiency and Cost-Efficiency

Laser engraving and etching processes showcase remarkable efficiency, significantly reducing production time in comparison to conventional methods. The automation and swiftness of laser cutting translate into expedited turnaround times, translating into financial savings for clients. Moreover, with minimal tool wear and a lack of physical contact between the laser and material, these processes are not only environmentally friendly but also cost-effective.

.

Non-Intrusive and Environmentally Friendly

The application of contact-free laser marking technology eliminates the necessity for direct contact with the processed material, mitigating the risks of damage, distortion, or contamination, especially in delicate applications. Furthermore, this method is generally environmentally friendly, devoid of chemicals or inks, ensuring the eco-friendliness of the end product.

Consistent Reproduction and Uniformity

The cutting-edge laser cutting technology at Charles Day Steels ensures remarkable consistency across each batch of engraved or etched items. Once a design or pattern is programmed, our laser cutters replicate it precisely across multiple pieces, guaranteeing uniformity in the final products. This level of consistency is particularly vital for businesses engaged in large-scale production of branded items or identical components.

Seamless Integration with CAD Software

Laser etching and engraving seamlessly integrate with computer-aided design (CAD) software, facilitating a seamless transition from digital designs to physical manifestations. This digital compatibility streamlines design modifications expedites prototyping, and facilitates efficient batch processing, allowing for swift iterations and improvements without compromising quality.

Why Choose Charles Day Steels for Laser Etching and Engraving Services?

Choosing between laser engraving and laser etching depends upon your chosen material, desired finish, and specific application. At Charles Day Steels, our dedicated team of professional metal profiling and laser marking experts can recommend the most appropriate method to produce optimum results.

We understand more than most that every project is different, and comes with its own challenges; by choosing Charles Day Steels for your laser etching and engraving project, you can rest assured that your project is in safe and capable hands.

Contact our team for expertly informed laser etching and engraving services today.

Quality Assurance

Quality. Accuracy. Compliance.

From drawing to delivery, Charles Day take pride in delivering quality profile cutting services to boost downstream efficiency and profitability.

Factory production controls comply with construction product regulation BS EN 1090 EXC4 for intricate cutting of construction and nuclear regulation profiles.

Certified to BS EN ISO 9001:2015 for all profiling requirements.