Angles up to 60 degrees

Here at Charles Day, our unrivalled metal profiling capabilities ensure the best quality parts are procured in a rapid turnaround. Offering some of the very best in metal profiling, we can provide weld preps and chamfers in angles up to 60 degrees on plates between 6mm to 60mm (greater thicknesses are available on request).

Weld preparation of metal parts carried out during the profiling process helps our customers save both time and money. Combining the cutting and beveling processes from a single source reduces the number of steps within the supply chain; improving efficiency and saving you money overall. We are also able to create expert weld preps on laser, waterjet, flame and plasma cut parts.

With industry-defining capabilities available on-site, we are able to produce top-face and bottom-face (or a combination of both) edge preps between 15° – 60°. Preps are commonly requested on metals such as stainless steel, mild steel, and aluminium, but we can also preform bevels on tough metals such as wear plate, duplex, super duplex, and Inconel.

Our weld preparations are suitable for single and double-sided, partial and full-penetration butt welds.

Weld Joint Configurations At Charles Day

Due to our unrivalled facilities, we are able to procure a range of joint configurations, some of which include…

Single Weld Prep

Also known as a bevel cut, the desired angle of the edge prep goes completely through the thickness of the plate.

Weld Prep With Root Face

Sometimes referred to as a chamfer, the contour of the edge prep only penetrates a proportion of the material thickness, leaving a partially flat edge.

Compound Weld Prep

Two different angle bevels are carried out on a single face.

Double Weld Prep With Root Face

A double weld prep features a bevel/chamfer on both the top face and bottom face of the plate.

Double Weld Prep Alternative Angles

A double weld prep features a bevel/chamfer on both the top face and bottom face of the plate.

J Weld Prep

Unlike straight chamfers, a J prep works off a set radius in order to create a smooth, curved edge.

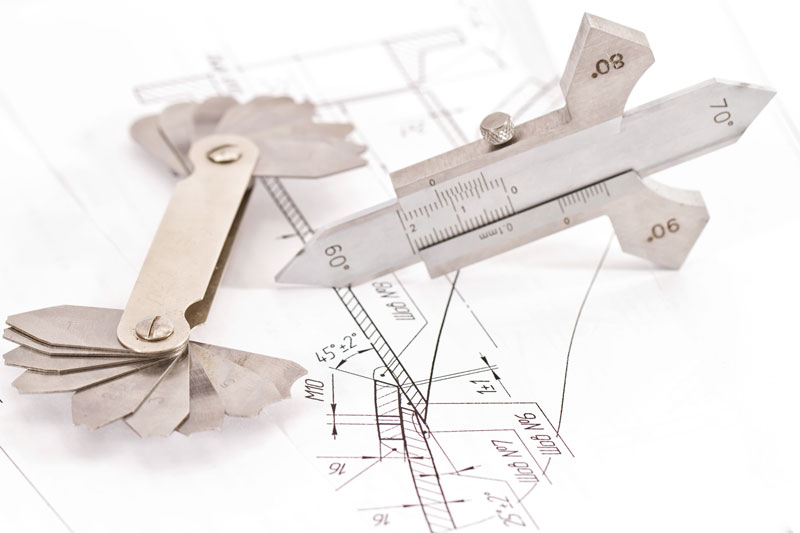

Why Choose Charles Day For Weld Preps and Chamfers?

At Charles Day, our commitment to providing the very best in metal profiling means we are dedicated to investing in only the most innovative and state-of-the-art technology for the benefit of our customers. Capable of processing a plethora of weld joint configurations, chamfers, and bevels, we always go above and beyond to provide a professional and timely service.

Versatile Capability

With a suite of high-spec machinery on site, and a series of extensive tooling libraries, even the most complex of projects can be procured efficiently. We can create weld preps and chamfers in angles up to 60 degrees on plates between 6mm to 60mm.

In-House Programming

With a team of CAD experts and a host of technology available on site, we are able to produce bespoke designs to support you in the early design stages. This ensures that your weld preps, chamfers and bevels are correct and procured in a timely manner.

One Stop Shop

Offering a fully comprehensive service, from sourcing materials, to in-house processing and timely delivery, we make procuring accurate parts for your project simple.

Robust Partner Network

We work closely with a range of trusted partner suppliers to ensure that even the most heavy duty or more complex of projects can be completed reliably to the highest quality possible.