Plasma Cutting Service

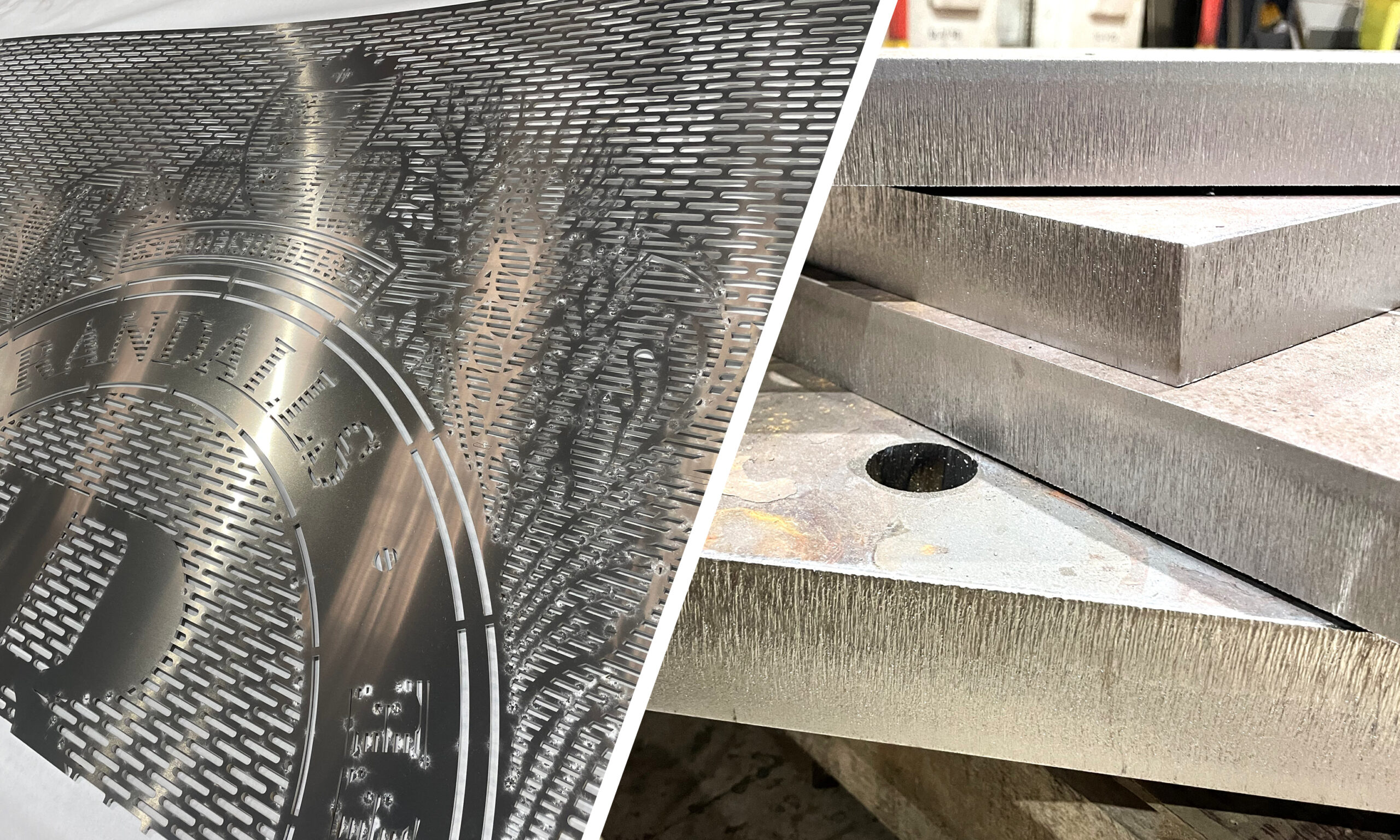

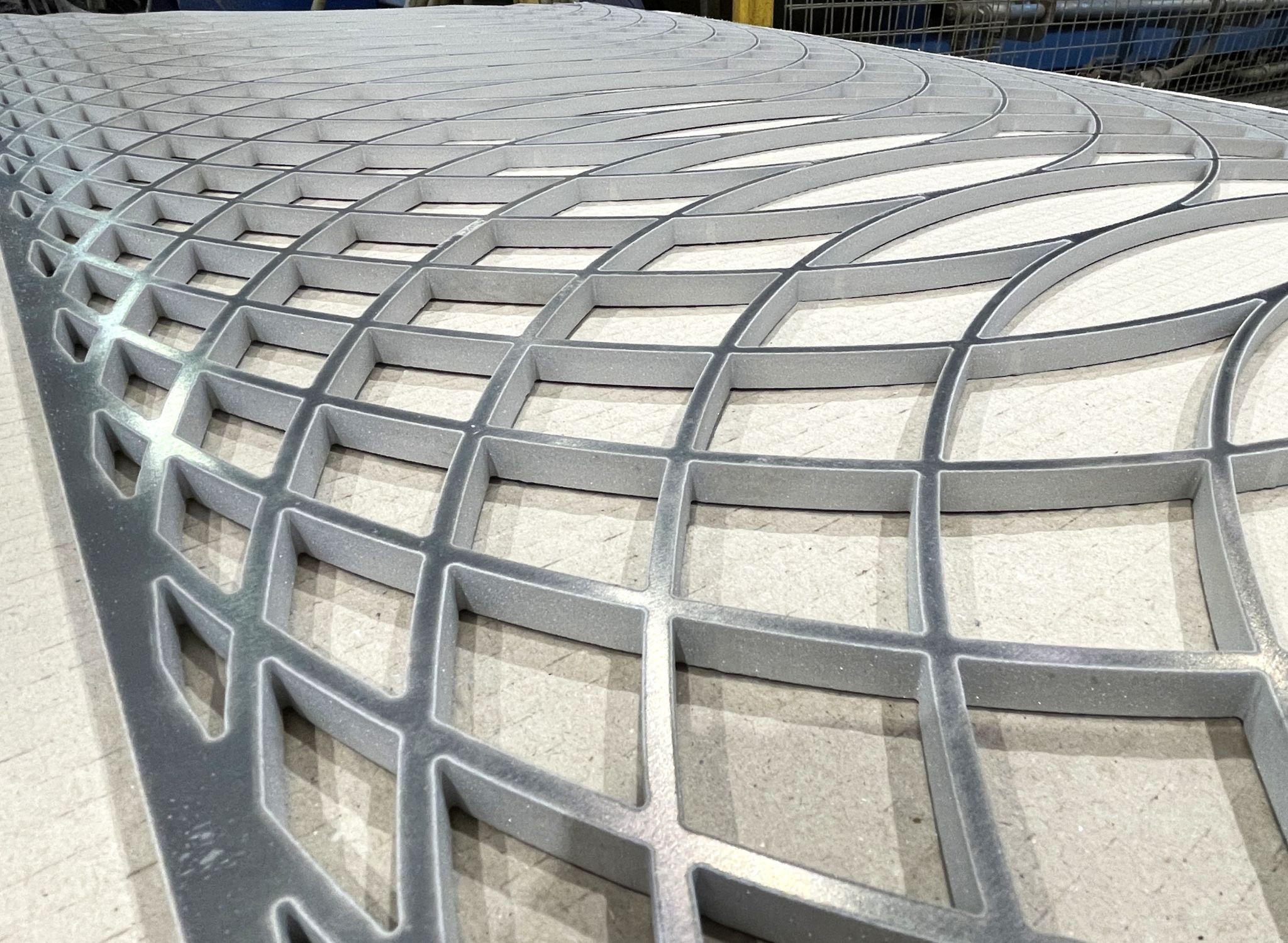

Often touted as an alternative to flame cutting, high-definition plasma cutting is perfect for profiling carbon/mild steels, aluminium, and stainless steel up to 40mm thick. Our twin-head plasma machine can handle sheets and plates up to 12mx5m.

With over 35 years of industry experience providing a high-definition plasma profiling service, Charles Day is proud to still offer this traditional and cost-effective method of profiling steel.

How Does Plasma Cutting Work?

Plasma cutting is a process of using a jet of ionised gas at temperatures above 20,000 °C to melt and expel material from the desired cut. High-definition plasma profiling has the advantage over flame cutting due to its ability to profile stainless steel and aluminium – alongside a vast array of carbon steels.

What Are The Benefits Of Plasma Cutting?

As well as providing a smoother cut edge compared to a flame, hi-def plasma cutting can also prove to be faster and cheaper than flame on certain thicknesses – if this is the case, we will always offer you the choice between cutting methods to ensure you get the best value profiled parts.

Our twin-head plasma cutting machine offers a cutting bed 12m x 5m and is an ideal choice for large sheets requiring a higher accuracy edge squareness than flame cutting.

All material grades are offered, and we keep many popular grades and thicknesses in stock. However, if we don’t have your desired material, we can usually source them within 48 hours. We will also happily cut your free-issue material if required.

HD Plasma Cut Materials

- Stainless Steel

- Carbon/Mild Steel

- Aluminium

HD Plasma Cutting Details

- Cutting thickness up to 30mm

- Carbon steels can be cut up to 40mm thick but we can only perform edge start cuts (i.e. no piercing cuts)

- Sheet/plate size up to 12m x 5m

- High-definition plasma machine for maximum edge squareness

- Full range of carbon and mild steels stocked in popular

HD Plasma Cutting Tolerances

- Thickness tolerance is in accordance with BS EN 10029:2010 Class A regulations.

- Flatness tolerance is in accordance with BS EN 10029:1991 regulations

- Profiling tolerance top face +/- 1.0mm.

- Edge squareness less than 3 degrees through part

Quality Assurance

Quality. Accuracy. Compliance.

From drawing to delivery, Charles Day take pride in delivering quality profile cutting services to boost downstream efficiency and profitability.

Factory production controls comply with construction product regulation BS EN 1090 EXC4 for intricate cutting of construction and nuclear regulation profiles.

Certified to BS EN ISO 9001:2015 for all profiling requirements.

FAQs

What is plasma cutting?

Plasma cutting is a simple and effective method of cutting through electrically conductive material via an accelerated jet of hot plasma.

What gas is used in plasma cutting?

Different gasses are required for differing materials. Oxygen is most commonly used for steel as it offers a speedier cutting time, however, nitrogen and argon are also used.

How much does plasma cutting cost?

The price depends entirely on the material and the amount that needs to be cut but is considered to be significantly less expensive than laser and flame cutting.

Can you cut aluminium with a plasma cutter?

Yes! – aluminium is a great material for plasma cutting, and is a highly effective method of cutting aluminium safely and efficiently.

What materials can be plasma cut?

Because plasma cutting utilises ionized gas to form a flame, any metal that is electrically conducive can be plasma cut. Some examples include steel, aluminium, bronze, copper, and brass.